Laser cutting machine and laser welding machines are widely used in the following industry, such as sheet metal fabrication, metallic job-shops,Elevator industry,Shipyard building industry,Food and drugs machine manufacturing, other machine manufacturing…

Advantages of Laser Welding Compared to Traditional Welding Technologies 1. High Depth-to-Width Ratio Laser welding achieves deep penetration with a narrow weld seam and a small heat-affected zone. The depth-to-width ratio can reach up to 20:1. &nbs...

With the rise of handheld welding machines, they are starting to be adopted in different industries, from smaller fields like hardware and stainless steel, home appliances and kitchen utilities, and electronic products, to larger areas like aerospace...

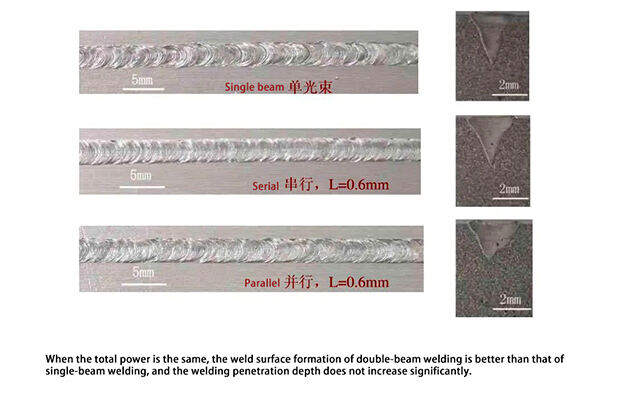

The dual-beam welding method has been proposed, mainly used to improve the adaptability of laser welding to assembly accuracy, increase the stability of the welding process, and improve weld quality, especially for the welding of thin plates and alum...

1.1 Focus plane 1.1.1 Focus Definition:The energy distribution of the beam cross-section is as shown in the left figure, and the longitudinal section of the beam energy distribution is also as shown in the left figure. The beam is output from the las...

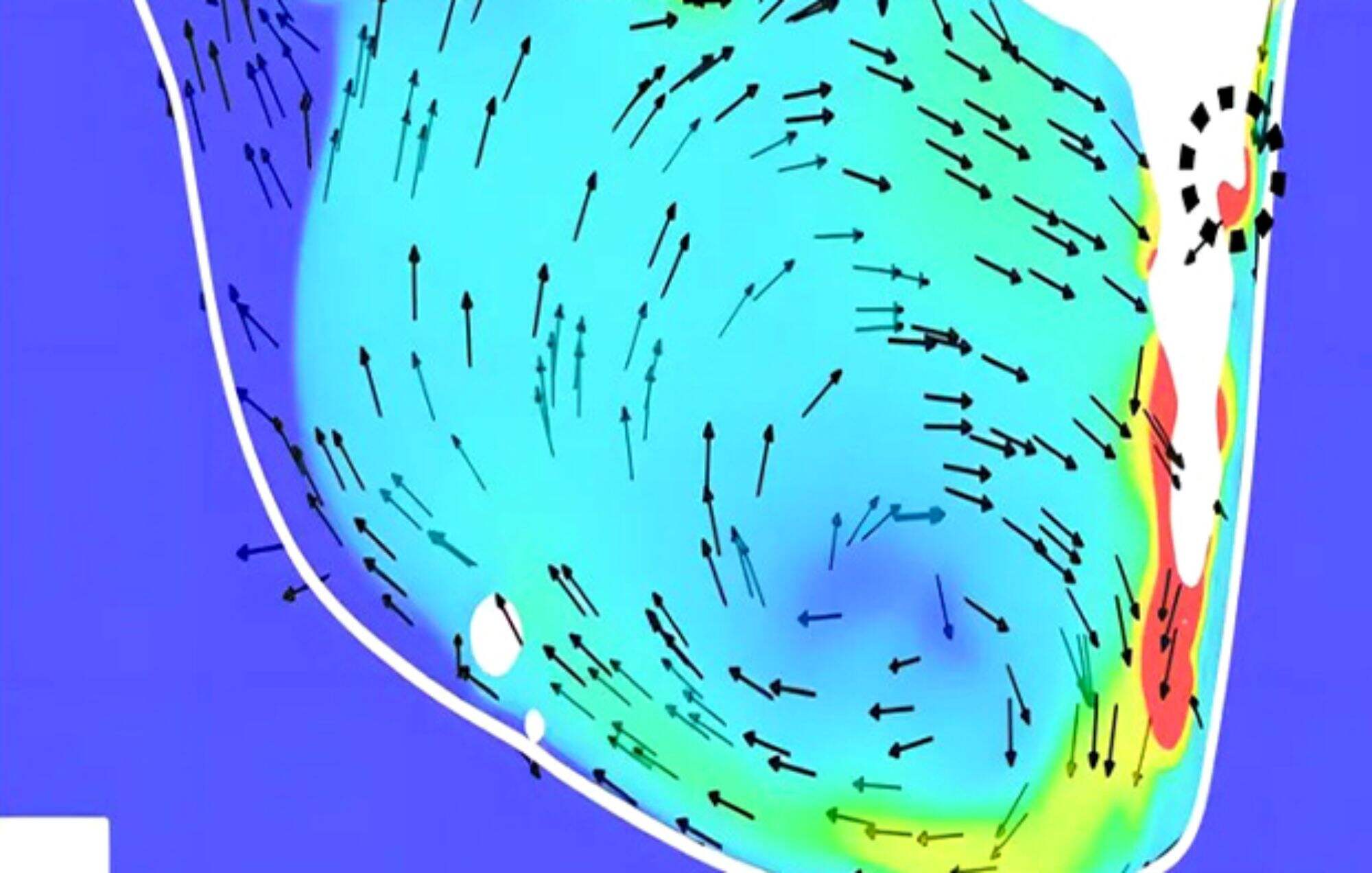

1.keyhole definition Keyhole definition: When the radiation intensity is greater than 10^6W/cm^2,When the surface of a material melts and evaporates under the action of a laser, and when the evaporation speed is sufficiently large, the recoil pressur...

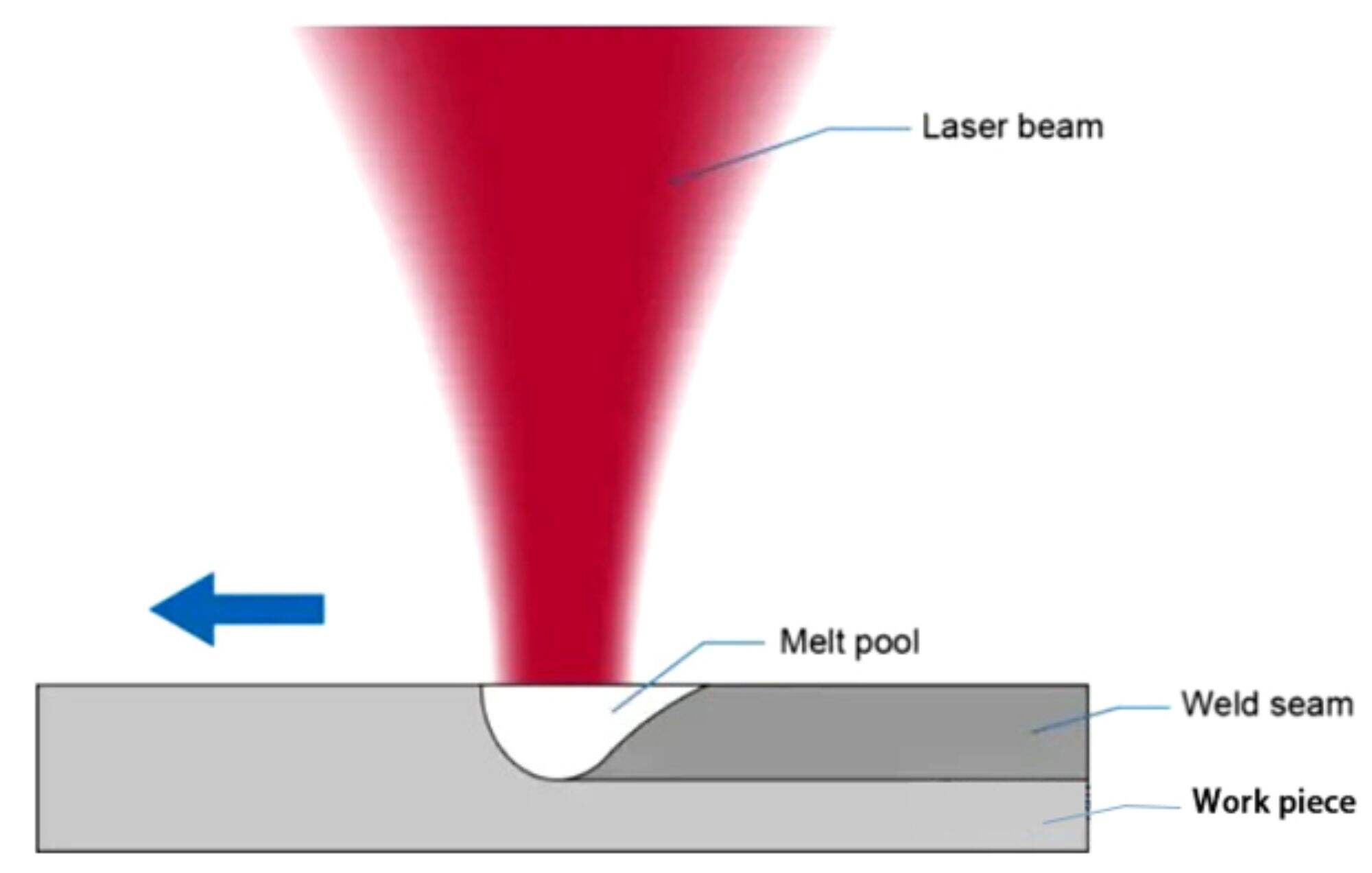

1.Laser thermal conductivity welding definition and characteristics Laser thermal conductivity welding is a method of laser welding. This welding mode has shallow penetration depth and small depth-to-width ratio.When the power density is less than 10...

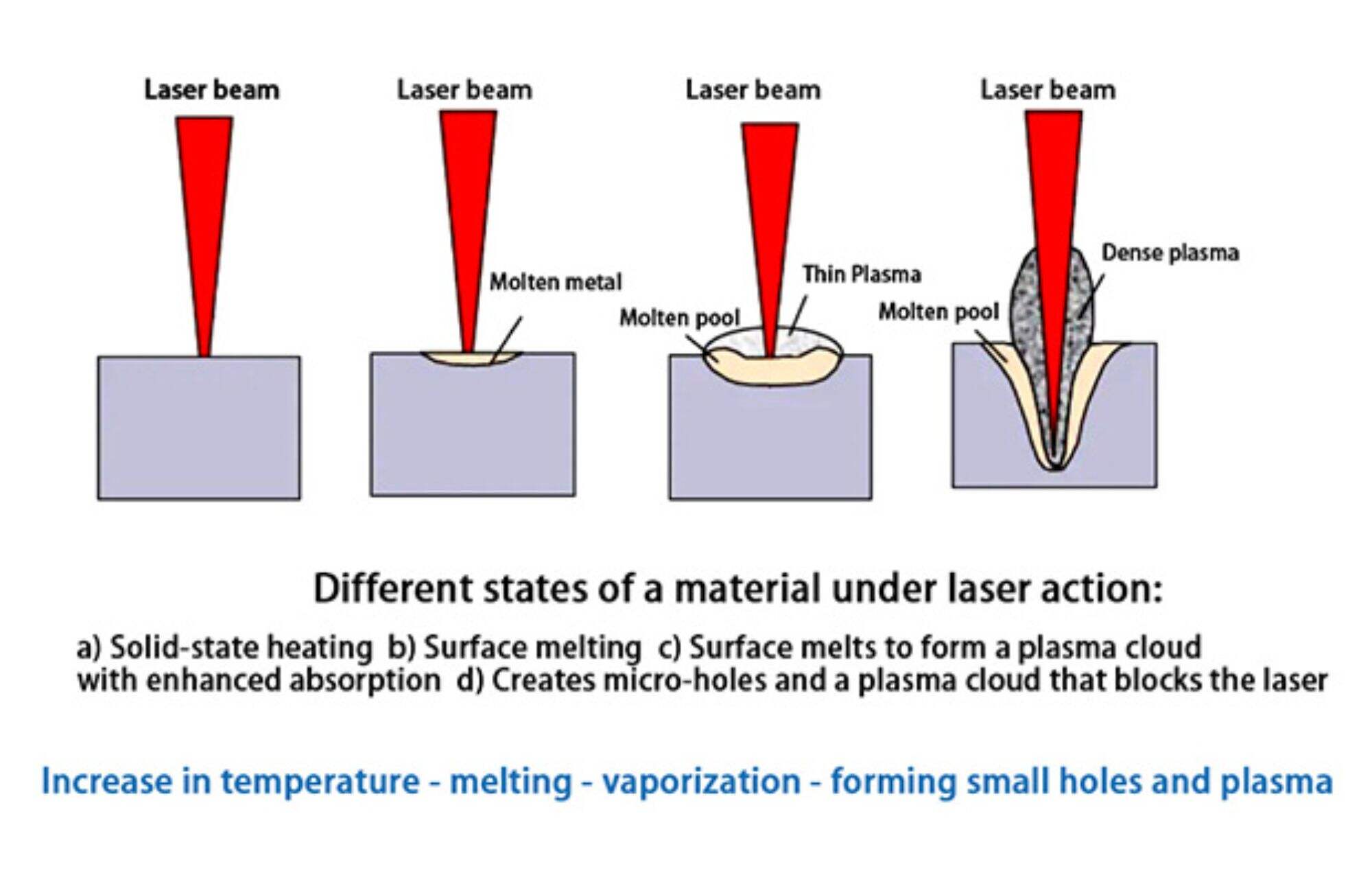

Plasma effect in laser welding process In the laser welding process, plasma is a common phenomenon, which has an important impact on the effect and quality of the welding process.Plasma is composed of ionized gas in which atoms or molecules in the ga...

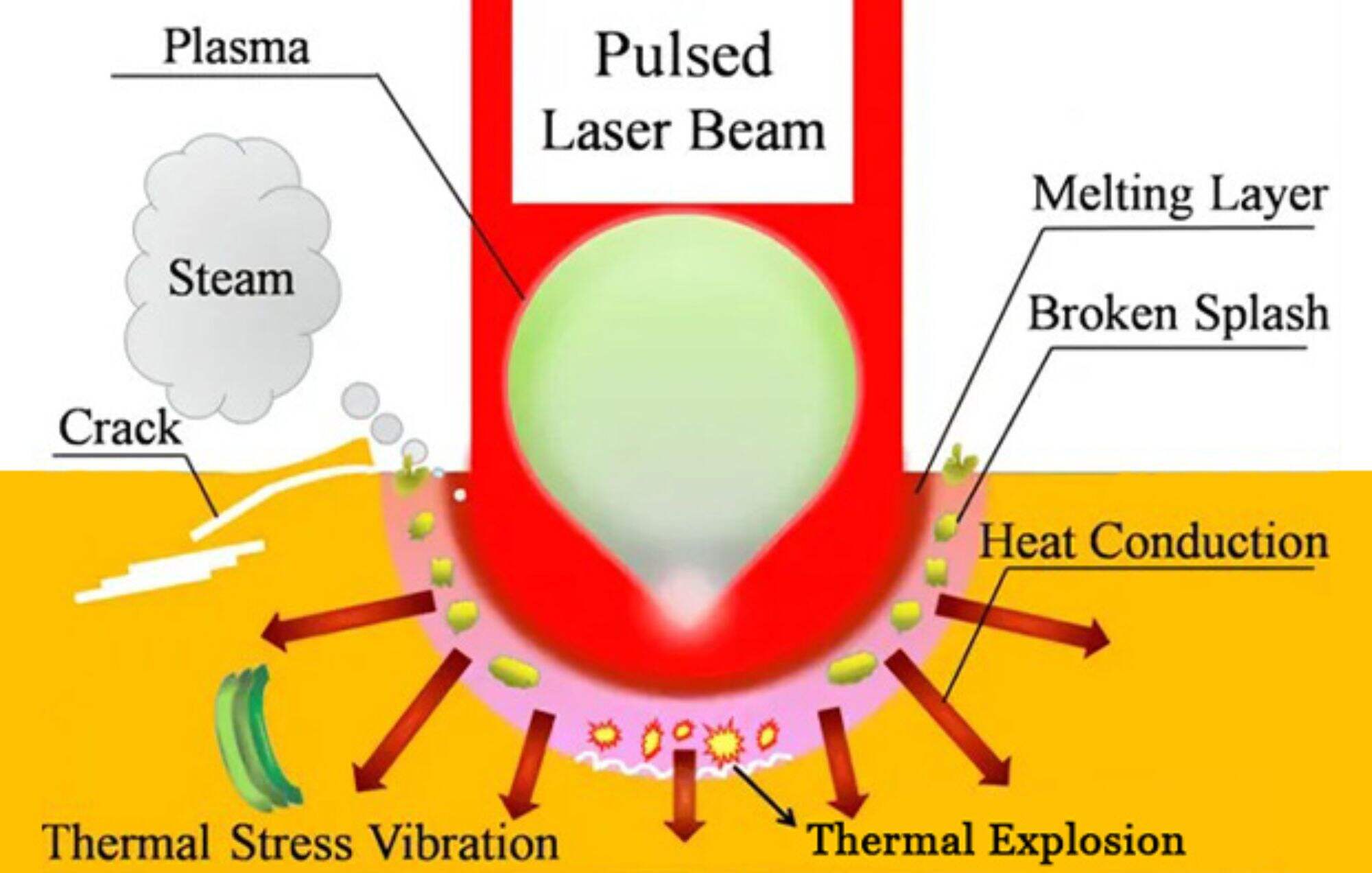

1.1 Changes in physical state caused by the interaction between laser and materials The laser processing of metallic materials is mainly a thermal processing based on photothermal effects. When the laser irradiates the surface of the material, variou...

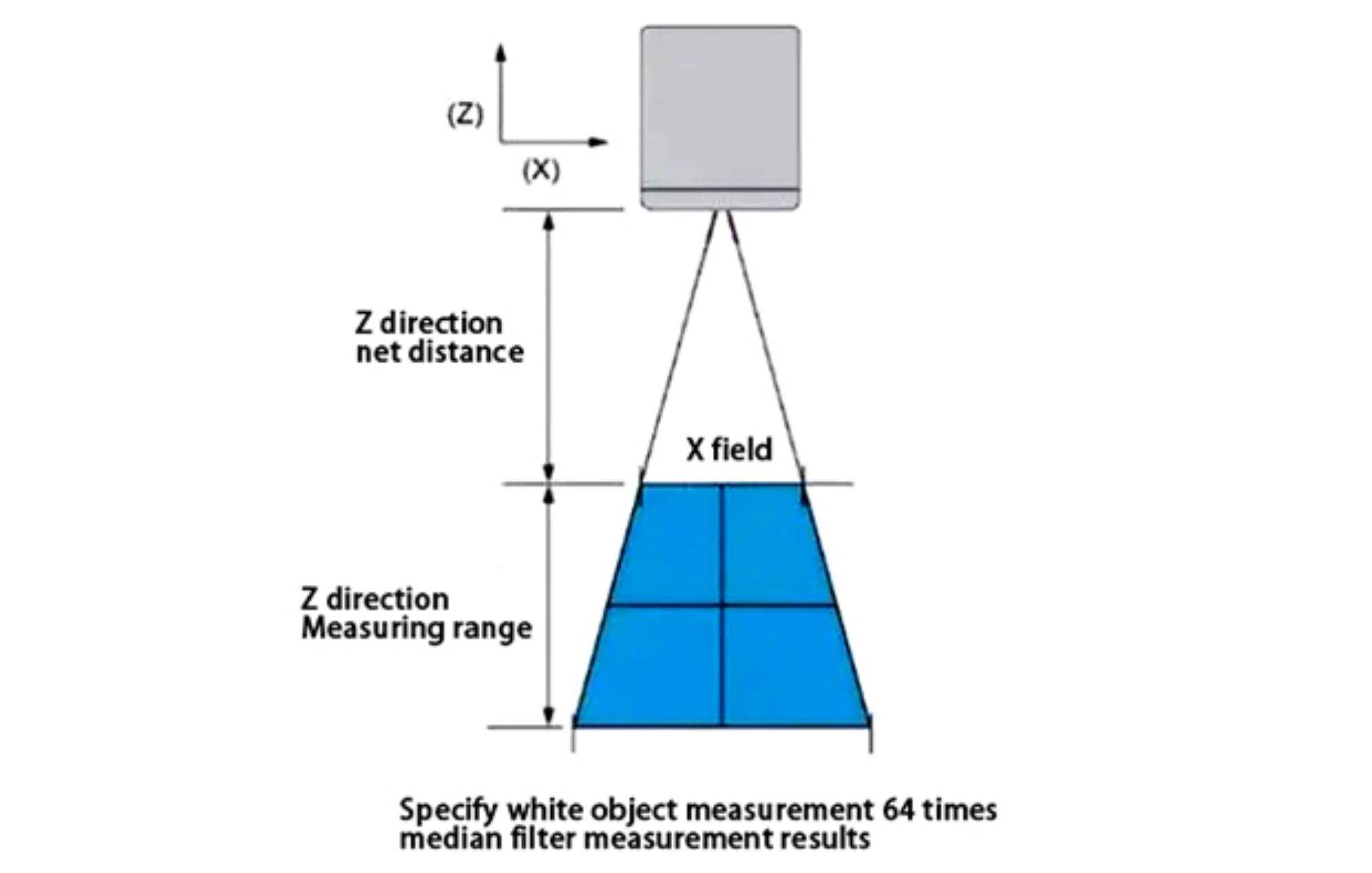

1.Laser weld seam tracking principle The laser-seam tracking sensor operates on the principle of laser triangulation. That is, the laser beam is amplified to form a laser line projected onto the surface of the object being measured. The reflected lig...