With the rise of handheld welding machines, they are starting to be adopted in different industries, from smaller fields like hardware and stainless steel, home appliances and kitchen utilities, and electronic products, to larger areas like aerospace...

Contact Us

With the rise of handheld welding machines, they are starting to be adopted in different industries, from smaller fields like hardware and stainless steel, home appliances and kitchen utilities, and electronic products, to larger areas like aerospace and automobiles. The surge in manufacturers of handheld laser welding machines has led to an uneven quality of products in the market, turning the choice of these machines into an important issue.

Many people take price into consideration when selecting a manufacturer of handheld laser welding machines. The quality of equipment varies with each manufacturer, as does the price. The pricing factor is not only related to the size of the manufacturer and their capabilities, but also the effect of the brand. Different construction and production processes result in different prices.

The choice of handheld laser welding machine manufacturers also depends on the choice of major component brands. Handheld laser welding machines consist principally of laser source, chillers, handheld welding heads, optical fibers, and sheet metal cabinets. The quality of the main components fundamentally determines the use quality of the equipment. Demark Laser cooperates with domestic and international well-known brands for the supply of core laser parts, promising to ensure the basic performance and lifespan of the equipment. The stability of the light source is also better than that of average brands.

Here, I have made a comparison between our DMK handheld laser welding machine and a similarly powered but cheaper handheld laser welding machine available in the market, unraveling the secret behind the cheapness of the latter. This comparison should give you a more intuitive understanding. After reading this article, I believe you will gain a completely new perspective on choosing a handheld laser welding machine!

1.Buttons and wiring of the control panel

|

Cheap: Buttons are plastic and labels are stickers |

DMK laser welder: The buttons are made of metal and the labels are laser marked. |

This is the operation screen and button area of the equipment. If we only look at the exterior, the differences between the two devices seem not so obvious. However, by pressing the buttons, we can clearly feel that the buttons of the relatively cheaper device are made of plastic, the material is light, and the bounce-back is quite slow. The buttons of this device rebound very smoothly, they also feel more solid, including a few other buttons that are made of metal. The material is quite substantial, and there is a clear difference in texture and aesthetics compared to this device. The overall durability of the DMK welding machine is also better.

Although the button is a relatively small part, there is a cost difference of nearly tens of dollars.

|

Cheap: The wiring is messy and there are no markings on the connections. |

DMK laser welder: Neat wiring, all marked |

Opening the front covers of the two devices, we can see the internal wiring. The wiring of the device in the upper left picture is somewhat chaotic, the connections are not marked, allowing for quicker installation and saving on labor time. However, it's not convenient to troubleshoot when a wiring problem occurs. Looking at the device in the right picture, the wiring is relatively neat and standard, and all are equipped with line markers. The level of formality is very intuitive. So, there is a clear difference in the labor costs of the two in terms of wiring.

2.AC contactor

|

Cheap: Unknown brand, CHNT |

DMK Laser welder:Schneider Electric |

Let's compare the AC contactors of these two devices. The device on the left uses CHNT from Zhengtai, while the one on the right uses Schneider Electric, an imported brand from Germany. There is a certain difference between the two in terms of cost. Of course, in terms of quality and performance stability, the DMK handheld welding device definitely has more advantages.

3.Filter

|

Cheap without filter |

Our welding machine has a filter |

The filter is a very crucial electronic component. Its main function is to effectively filter out high-frequency noise. Comparing our device on the right, we see that the device in the left picture does not have a filter installed. We all know that due to unstable current in many countries, its use could lead to circuit faults and damage to the laser due to unstable current factors. It also presents certain safety hazards for the operators.

A device equipped with a filter can screen out spikes, noise, electromagnetic interference and other clutter signals generated in the output signal, effectively protecting the circuit and maintaining the normal operation of the system. This greatly reduces the risk of device failure.

4.Chiller alarm line

|

|

This is the alarm line for the chiller. The chiller alarm line of the device on the left (the inexpensive one) is not connected. This may cause the chiller to burn out directly during operation if improperly used. This might subsequently result in a series of fault chain reactions, even damaging the laser source. On the other hand, the device on the right (DMK welding machine) is equipped with an equal-line terminal. There are connections to the chiller, the laser, and the control light wiring, all neatly arranged. The circuit markings are also very clear. As soon as a fault occurs in the chiller, an immediate alarm is given to stop the device from working, investigate the fault, and thus minimize the risk of device damage.

5.Power cord length

|

|

The cheap one has only 1.5m, and our power cord is 10m. It also includes a key part of the power cord. We all know that the equipment in use is restricted by the power supply of the workplace. If the line is too short, it will greatly affect the mobility of the equipment, especially for users who do not have extended power cord coils.

We can see that the power cord of this device (the cheaper one) is only 1.5m, while this device (DMK) is equipped with a 7m power cord. We feel the difference through a straightforward unfold for comparison. Therefore, the convenience of the power cord length during use is very significant. Of course, the length of the line also makes a distinct difference in terms of cost.

6.Laser machine details

|

|

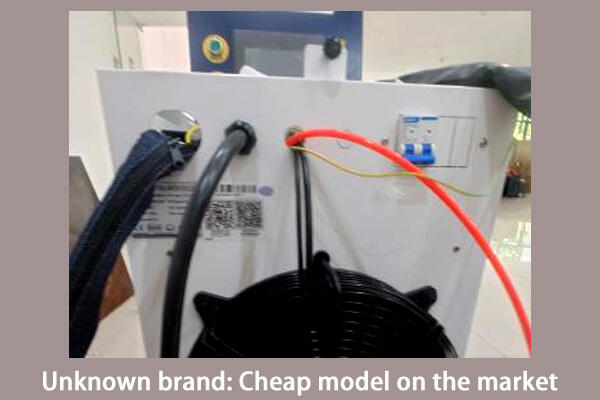

Let's take a look at the wiring treatment on the back of the device, where there are also some differences in detail. The wiring on the back of the device (the cheaper one) on the left has not been fixed, it is easy to pull excessively during operation, which leads to loose wiring and creates a risk of circuitry connection failure.

The fixed wiring component on this DMK welding machine on the left is very sturdy, and it remains stable even if we pull on it randomly. This includes various other treatments on the back, such as structural processing and detailed wiring treatment, which are standardised.

Through the direct comparison of the devices above, we should be able to very intuitively see that the differences in the parts and process details of different devices bring about not only differences in parts and labor costs, but also invisibly affect the repair risks and costs of the device in future use. It may even affect the efficiency of work production.

Therefore, when we select laser welding equipment, we first need to consider the material and thickness of the product we process, the development and production capabilities of the handheld laser welding machine manufacturer, and its after-sales service capabilities, among other factors. We should choose a laser welding machine that can achieve the processing effect of the enterprise and bring benefits to the enterprise. Only in this way can we make the right choice.