Laser cutting machine and laser welding machines are widely used in the following industry, such as sheet metal fabrication, metallic job-shops,Elevator industry,Shipyard building industry,Food and drugs machine manufacturing, other machine manufacturing…

The rail locomotive industry robot laser cleaning and derusting machine is a kind of equipment specially used for cleaning and removing the rust on the surface of rail locomotives.

The three-dimensional laser cutting machine for special-shaped materials in the automotive industry is a special equipment for cutting special-shaped materials in the automotive industry.

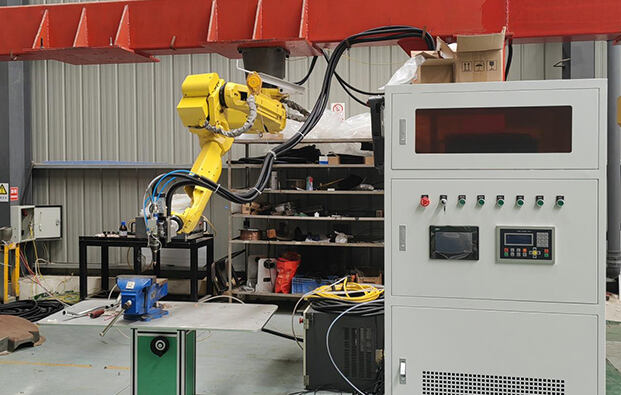

The robot laser welding machine manufactured by our company is composed of Eston six-axis industrial robot, MAX continuous fiber laser, Qilin BWT30 light double pendulum laser welding head and Hanli chiller, etc.

For craftsmen, manufacturers, and business owners, choosing the right glass laser marking machine is key to unlocking the value of glass processing. A suitable device can transform ordinary glass into high-quality products with personalized designs o...

The safety of laser technology in glass marking is a core concern for users. The answer is clear: laser marking on glass is completely safe when using professional equipment and strictly following operational procedures. For professional manufacturer...

With the rapid development of the automotive industry, the remanufacturing of high-value parts from end-of-life vehicles has become a crucial link in resource recycling. As the core component of automobiles, transmissions—especially components ...

In fields such as industrial rust removal, cultural relic restoration, and precision component cleaning, laser cleaning is gradually replacing traditional processes like chemical cleaning and mechanical grinding, thanks to its non-contact, non-damagi...

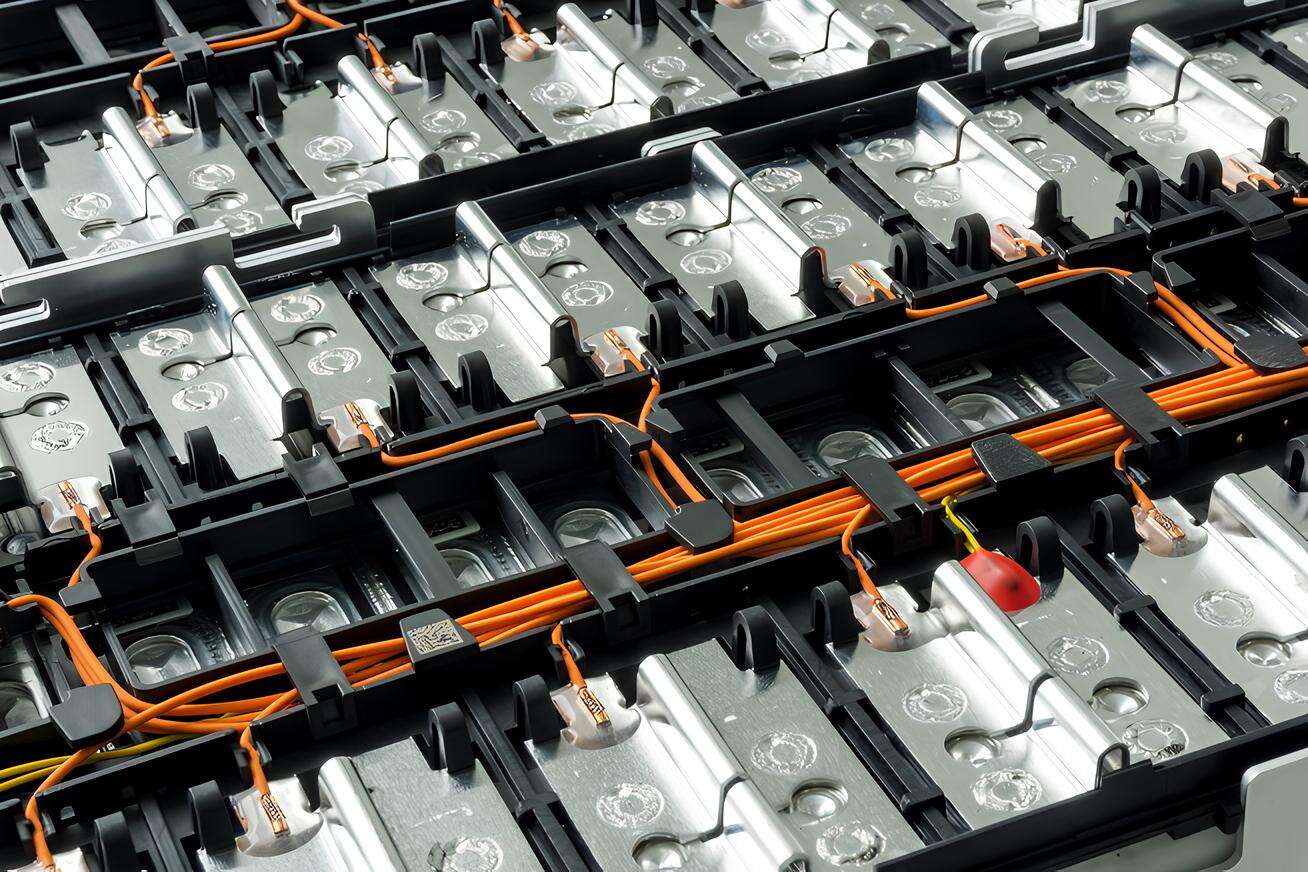

Choosing the right automated welding machine for battery manufacturing is not about chasing the latest technology blindly—it’s more like finding the perfect piece in a complex puzzle, precisely aligning with your production needs, budget ...

As the core component of most electric vehicles, prismatic battery packs must withstand thousands of charge-discharge cycles, extreme temperatures, and continuous vibrations. Their thin aluminum and copper tabs are highly vulnerable to damage, but mo...