The dual-beam welding method has been proposed, mainly used to improve the adaptability of laser welding to assembly accuracy, increase the stability of the welding process, and improve weld quality, especially for the welding of thin plates and alum...

Contact Us

The dual-beam welding method has been proposed, mainly used to improve the adaptability of laser welding to assembly accuracy, increase the stability of the welding process, and improve weld quality, especially for the welding of thin plates and aluminum alloys.Dual-beam laser welding can separate the same type of laser into two separate beams for welding using optical methods, or it can use two different types of lasers for combination. CO2 lasers, Nd:YAG lasers, and high-power semiconductor lasers can all be combined with each other.By changing the energy of the beams, the distance between the beams, and even the energy distribution pattern of the two beams, the welding temperature field can be adjusted conveniently and flexibly. This changes the existence mode of holes and the flow mode of liquid metal in the weld pool, providing a wider choice of space for the welding process, which is unmatched by single-beam laser welding.Not only does it possess the advantages of deep fusion, fast speed, and high precision of laser welding, but it also has great adaptability to materials and joints that are difficult to weld with conventional laser welding.

1.Dual-beam laser welding principle

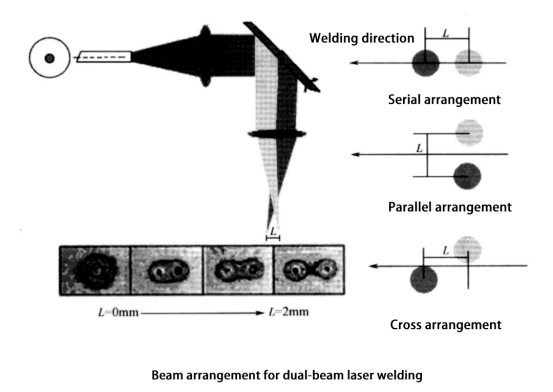

Dual-beam welding means using two lasers simultaneously during the welding process. The beam arrangement, beam spacing, angle formed by the two beams, focusing position, and energy ratio of the two beams are all relevant setup parameters in dual-beam laser welding.Normally, during the welding process, there are generally two ways of arranging the dual beams. As shown in the figure, one is to arrange them in a series along the welding direction. This layout can reduce the cooling rate of the weld pool and decrease the hardening tendency of the weld and the production of porosity. The other is to arrange or cross the beams side by side on both sides of the weld seam to increase the adaptability to the gap in the weld seam.

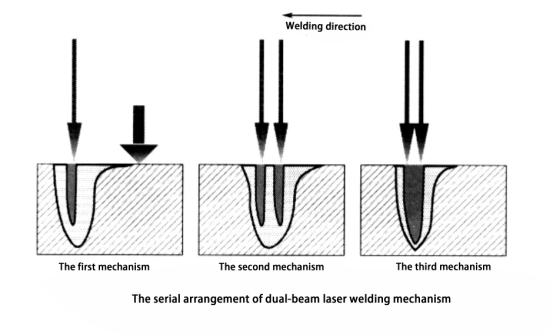

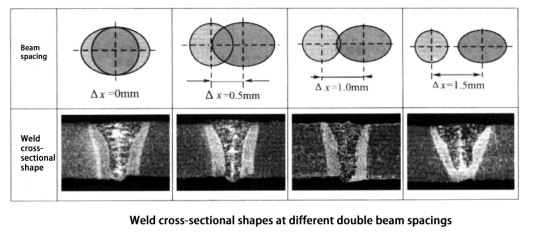

For a dual-beam laser welding system with a serial arrangement, there are three different welding mechanisms depending on the spacing between the two beams.

1)In the first type of welding mechanism, the spacing between the two beams is relatively large. One beam has a higher energy density and is focused on the surface of the workpiece to produce a keyhole in welding; while the other beam has a lower energy density and only serves as a heat source for pre or post-welding heat treatment.This welding mechanism allows the cooling rate of the welding pool to be controlled within a certain range, which is conducive to the welding of materials with high crack sensitivity such as high carbon steel and alloy steel, and it can also improve the toughness of the weld seam.

2)In the second type of welding mechanism, the distance between the focal points of the two beams is relatively small. The two beams produce two separate keyholes in a single welding pool, causing a change in the flow pattern of the molten metal. This helps prevent defects such as undercut and weld bead protrusion, improving weld seam formation.

3)In the third type of welding mechanism, the distance between the two beams is very small, and at this time, the two beams produce the same keyhole in the welding pool. Compared to single-beam laser welding, the size of this keyhole is larger and less likely to close, making the welding process more stable, and the gas is easier to discharge. This is beneficial in reducing porosity, spatter, and achieving a continuous, uniform, and attractive weld seam.

During the welding process, the two laser beams can also be set at a certain angle to each other, and its welding mechanism is similar to the parallel dual-beam welding mechanism. Experimental results have shown that, by employing two high-power OO laser beams at a 30° angle to each other and spaced 1~2mm apart, a funnel-shaped keyhole can be achieved. The keyhole is larger and more stable, which can effectively improve the welding quality. In actual applications, different combinations of the two beams can be adjusted according to different welding conditions to achieve different welding processes.

2.Implementation method of dual-beam laser welding

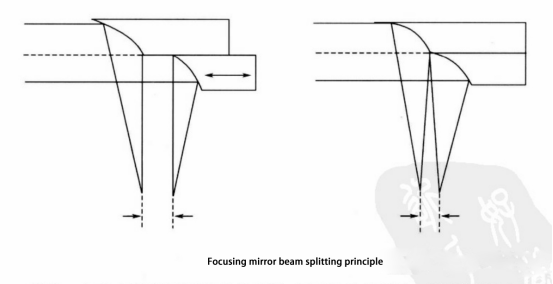

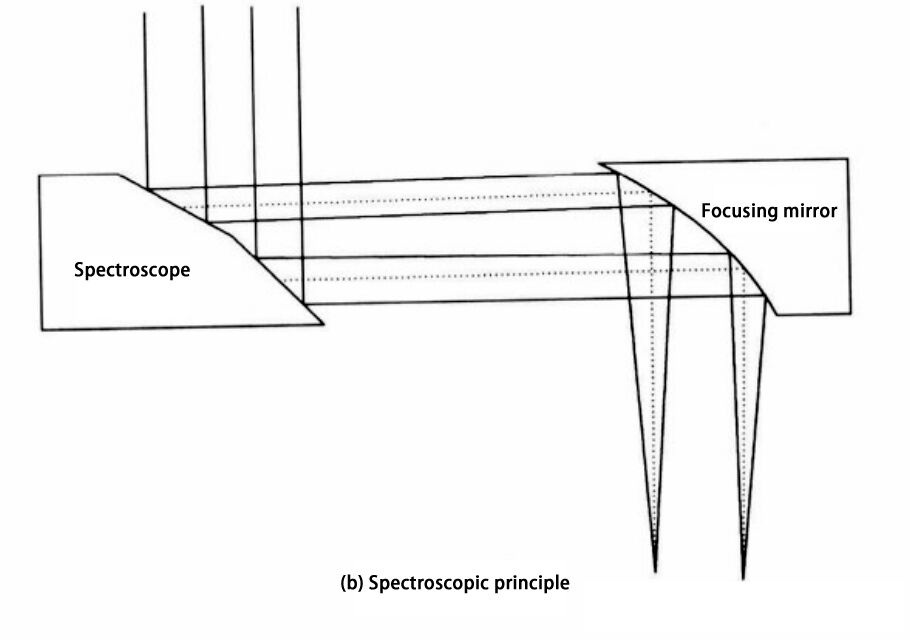

Obtaining dual beams can be achieved by combining two different laser beams, or by using an optical beam-splitting system to split one laser beam into two for welding.To separate a beam into two different power, parallel lasers, a beam-splitting mirror or some special optical systems can be used. The picture shows two types of beam-splitting principles using a focusing lens as the beam-splitter.

In addition, a reflector can be used as a beam-splitting mirror, with the last reflector in the optical path serving as the beam splitter. This type of reflector is also known as a ridge reflector, its reflecting surface is not a single plane but composed of two planes. The intersecting line of the two reflective surfaces is located in the middle of the mirror, resembling a ridge, as shown in the figure.A parallel beam of light is projected onto the beam-splitter and is reflected into two beams by two planes at different angles. These beams illuminate different positions on the focusing lens, and after focusing, two beams with a certain spacing are obtained on the surface of the workpiece. By changing the angle between the two reflecting surfaces and the position of the ridge, beam-splitting light beams with different focal spacing and arrangement methods can be obtained.

When using two different types of laser beams to form a dual beam, there are various combination methods. A high-quality CO2 laser with a Gaussian energy distribution can be used for primary welding work, assisted by a semiconductor laser with a rectangular energy distribution for heat treatment work.This combination method is economical on the one hand, and on the other hand, the power of the two beams can be adjusted independently. For different joint forms, an adjustable temperature field can be obtained by adjusting the overlap position of the laser and semiconductor laser, which is very suitable for welding process control. In addition, YAG laser and CO2 laser can be combined into a dual beam for welding, continuous laser and pulsed laser can be combined for welding, and focused beam and defocused beam can also be combined for welding.

3.Dual-beam laser welding principle

3.1 Dual-beam laser welding of galvanized sheet

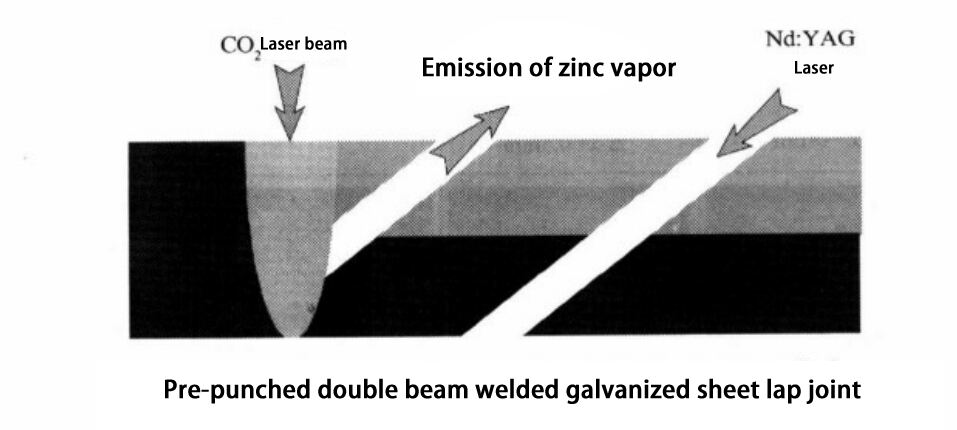

Galvanized steel plate is the most commonly used material in the automotive industry. The melting point of steel is around 1500°C, while the boiling point of zinc is only 906°C. Therefore, when using the welding method, a large amount of zinc vapor is usually generated, causing instability in the welding process and forming air holes in the weld seam.For lap joints, the volatilization of the galvanized layer not only occurs on the upper and lower surfaces, but also at the joint interface. During the welding process, zinc vapor rapidly sprays out of the molten pool surface in some areas, while in other areas it is difficult for zinc vapor to escape from the surface of the molten pool, resulting in very unstable welding quality.

Dual-beam laser welding can solve the welding quality issues caused by zinc vapor. One method is to control the existence time and cooling speed of the molten pool by reasonably matching the energy of the two beams, which is beneficial for the escape of zinc vapor; another method is to release zinc vapor through pre-drilling or grooving treatment.As shown in the figure below, CO2 lasers are used for welding, with YAG lasers on the front side of the CO2 laser used for drilling or cutting grooves. The pre-processed holes or slots provide an escape route for zinc vapor generated during subsequent welding, preventing it from staying in the molten pool and forming defects.

3.2 Dual-beam laser welding of aluminum alloy

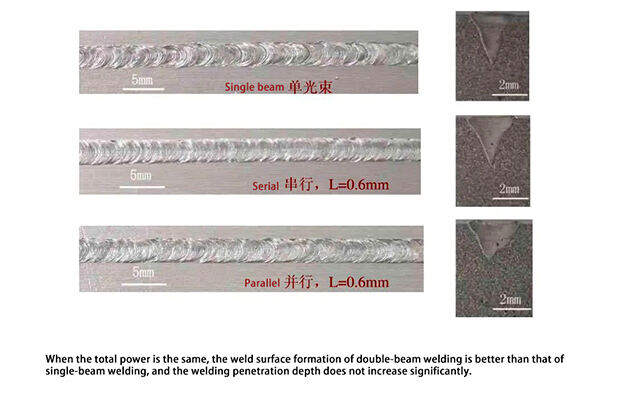

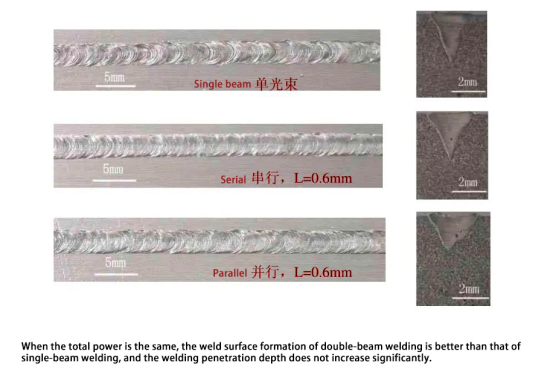

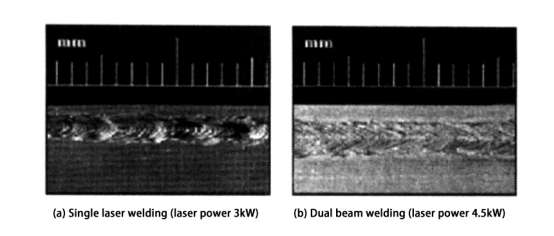

Due to the unique properties of aluminum alloy materials, laser welding presents the following difficulties: the absorption rate of the laser by aluminum alloys is low, with the initial reflection rate on the surface of the CO2 laser beam exceeding 90%; while welding, aluminum alloy laser weld seams are prone to porosity and cracks; there is loss of alloy elements during the welding process. When using single laser welding, it is difficult to establish keyholes, and they are not easy to maintain stability.When using dual-beam laser welding, the size of the keyhole can be increased, making it difficult for the keyhole to close and facilitating gas exhaust. At the same time, it can reduce the cooling rate, reducing the occurrence of pores and welding cracks. Because the welding process is more stable and the amount of spatter is reduced, the surface forming of the weld obtained by dual-beam welding of aluminum alloys is also significantly better than that of a single beam. The figure below shows the appearance of butt joints of 3mm thick aluminum alloys welded with a single CO2 laser beam and two laser beams.

Research shows that when welding a 2mm thick 5000 series aluminum alloy, the process is relatively stable when the distance between the two beams is 0.6~1.0mm. The resulting keyhole opening is larger, which facilitates the evaporation and escape of magnesium elements during the welding process.If the distance between the two beams is too small, the process will be similar to single-beam welding and will not easily be stable; if the distance is too large, it will affect the welding penetration depth, as shown in the figure below.In addition, the energy ratio of the two beams also has a significant impact on the welding quality. When two beams are arranged in series for welding at a distance of 0.9mm, it is beneficial to appropriately increase the energy of the prior beam, making the energy ratio of the two beams greater than 1:1. This helps to improve the quality of the weld, enlarge the melting area, and still achieve smooth and aesthetically pleasing welds even at higher welding speeds.

3.3 Dual beam welding of plates of unequal thickness

In industrial production, it is often necessary to weld two or more metal sheets of different thicknesses and shapes together to make a spliced sheet. Especially in car manufacturing, the application of spliced sheets is becoming more and more widespread.

By welding together sheets of different specifications, surface coatings, or performance, it can increase strength, reduce consumption, and reduce weight. In splicing plate welding, laser welding of plates of different thicknesses is usually used. A major issue is the necessity of prefabricating the workpieces to be welded with highly precise edges, and ensuring high-precision assembly.The use of double beam welding for plates of unequal thickness can adapt to varying gaps, docking parts, relative thicknesses, and material differences of the sheets. It can weld sheets with larger edge and gap tolerances, improving welding speed and weld quality.

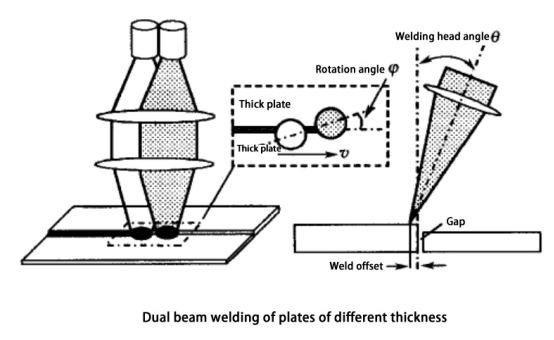

The main process parameters of double beam welding for plates of unequal thickness can be divided into welding parameters and plate parameters, as shown in the figure. Welding parameters include the power of the two lasers, welding speed, focal point position, welding head angle, beam rotation angle of the double beams on the butt joint, and welding deviation. Plate parameters include material dimensions, performance, edge trimming, and plate gap. The power of the two lasers can be adjusted separately according to different welding purposes.

Generally, a stable and efficient welding process can be achieved when the focal point is on the surface of the thin sheet. The welding head angle is usually chosen to be around 6 degrees. If the thickness of the two plates is quite large, a positive welding head angle can be adopted, i.e., the laser is tilted towards the thin plate as shown in the figure. When the plate thickness is relatively small, a negative welding head angle can be used. The welding deviation is defined as the distance between the laser focal point and the edge of the thick plate. By adjusting the welding deviation, the weld concavity can be reduced to achieve a good weld cross-section.

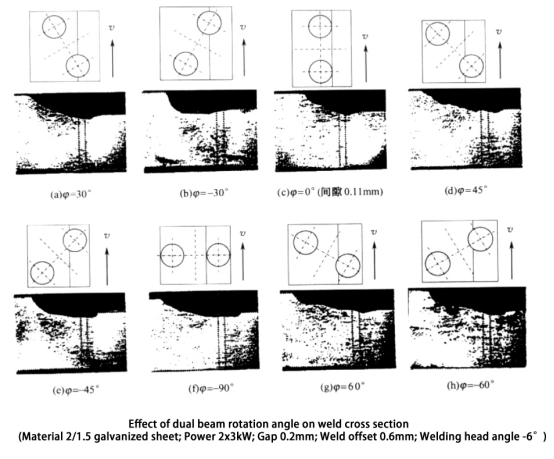

When welding plates with large gaps, the effective beam heating diameter can be increased to achieve good gap filling ability by rotating the double beam angle. The width of the top of the weld seam is determined by the effective beam diameter of the two lasers, that is, determined by the beam rotation angle. The larger the rotation angle, the wider the double beam heating range, and the wider the upper width of the weld seam.The two lasers play different roles during the welding process; one is mainly used to penetrate the joint, and the other is mainly used to melt thick plate material to fill the gap. As shown in the figure below, under a positive beam rotation angle (the front beam acts on the thick plate, the rear beam acts on the seam), the front beam impinges on the thick plate, heating and melting the material, and the following laser beam produces penetration.The first laser beam at the front can only partially melt the thick plate, but it makes a significant contribution to the welding process because it not only melts the side of the thick plate for better gap filling, but also pre-connects the joint material, making it easier for the following beam to penetrate the joint, thereby improving the welding speed.In the dual beam welding with a negative rotation angle (the front beam acts on the weld seam, the rear beam acts on the thick plate), the roles of the two beams are just opposite. The front beam penetrates the joint, and the rear beam melts the thick plate to fill the gap.

In this case, the front beam has to penetrate the cold plate, the welding speed is lower than that with a positive beam rotation angle. And, due to the preheating effect of the front beam, the following beam will melt more thick plate material at the same power.In this case, the power of the second laser beam should be appropriately reduced. In comparison, adopting a positive beam rotation angle can appropriately increase welding speed, while adopting a negative beam rotation angle can achieve better gap filling. The following image shows the effects of different beam rotation angles on the cross-section of the weld seam.

3.4 Dual-beam laser welding of thick plates

With the improvement of laser power levels and beam quality, it has become a reality to use laser welding for thick plates. However, due to the high cost of high-power lasers, and the general need for metal filling in thick plate welding, there are certain limitations in actual production.The use of dual-beam laser welding technology not only improves laser power but also increases the effective beam heating diameter, enhances the ability to melt filler wire, and stabilizes the laser keyhole, improving welding stability and thereby enhancing welding quality.