1.Laser weld seam tracking principle The laser-seam tracking sensor operates on the principle of laser triangulation. That is, the laser beam is amplified to form a laser line projected onto the surface of the object being measured. The reflecte...

Contact Us

1.Laser weld seam tracking principle

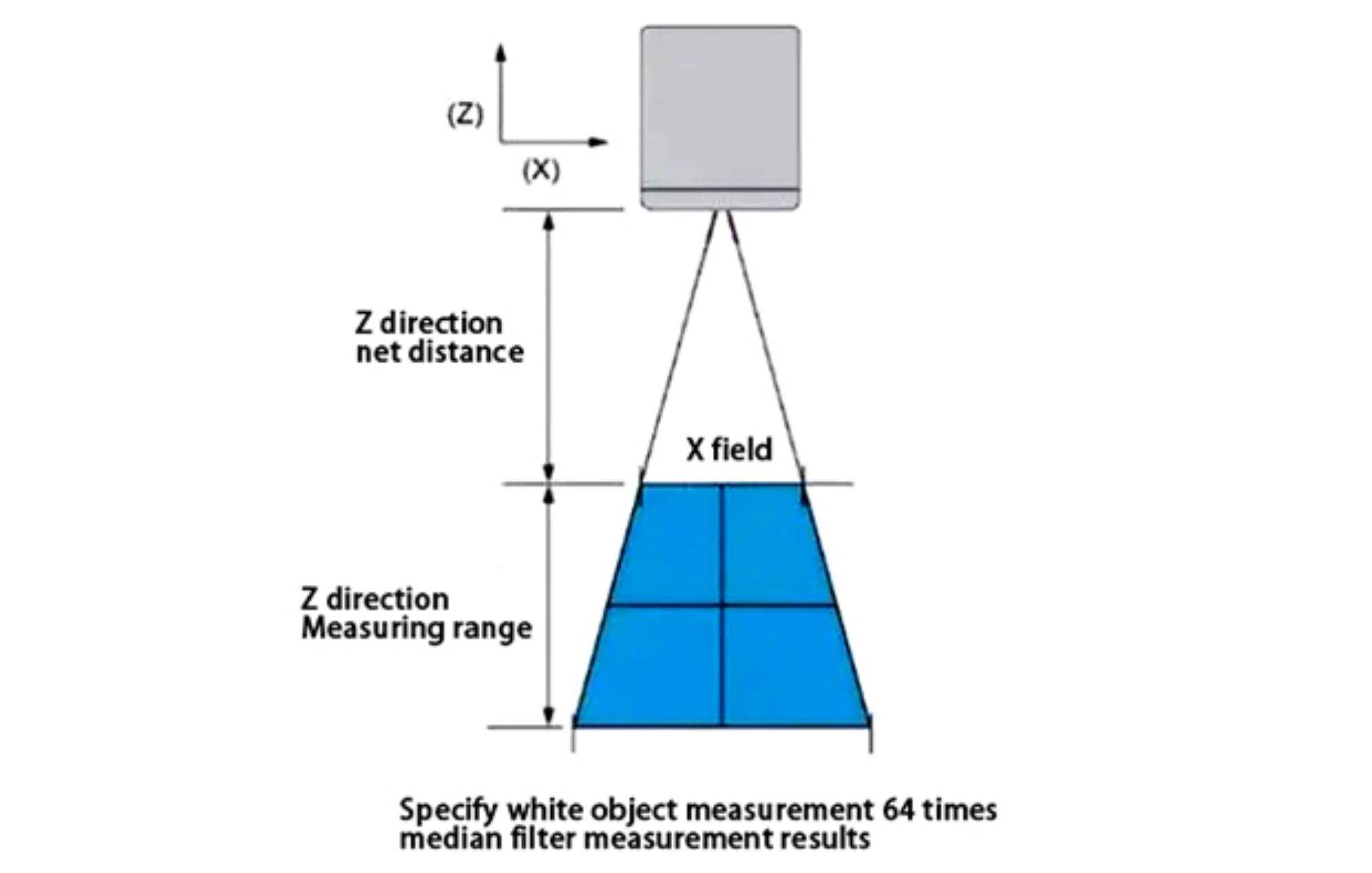

The laser-seam tracking sensor operates on the principle of laser triangulation. That is, the laser beam is amplified to form a laser line projected onto the surface of the object being measured. The reflected light passes through a high-quality optical system and is projected onto an imaging matrix. Through calculation, the distance from the sensor to the measured surface (Z-axis) and the position information along the laser line (X-axis) is obtained.By moving the object being measured or the profiler probe, a set of three-dimensional measurements can be obtained. The information obtained can be used for weld seam search and positioning, seam tracking, adaptive welding parameter control, and seam formation detection. This information is transmitted in real time to the robot unit to complete various complex welding tasks, avoid deviations in welding quality, and achieve unmanned welding.

Sensor model and parameters

| model |

X on site (mm ) |

Z net distance (mm ) |

Z Measuring range (mm) |

X resolution (mm) |

Z resolution (mm) |

Z linear Accuracy (%) |

Zrepeat Accuracy (%) |

| HD6-0007(Blu-ray) | 7 | 27 | 6 | 0.007 | 0.0006 | ±0.2 | 0.001 |

| HD6-0020(Blu-ray) | 20 | 60 | 20 | 0.021 | 0.0017 | ±0.2 | 0.002 |

| HD6-0032(Blu-ray) | 32 | 77 | 20 | 0.035 | 0.0028 | ±0.2 | 0.003 |

| HD6-0050(Blu-ray) | 50 | 170 | 50 | 0.058 | 0.015 | ±0.2 | 0.003 |

| HD6-0090(Blu-ray) | 90 | 130 | 70 | 0.11 | 0.024 | ±0.2 | 0.003 |

| HD6-0150 (red light and blue light optional) | 150 | 300 | 175 | 0.185 | 0.047 | ±0.3 | 0.004 |

| HD6-0200 (red light and blue light optional) | 200 | 350 | 125 | 0.245 | 0.064 | ±0.3 | 0.004 |

| HD6-0300 (red light and blue light optional) | 300 | 550 | 210 | 0.394 | 0.126 | ±0.3 | 0.005 |

| HD6-0500(red light) | 500 | 400 | 400 | 0.792 | 0.254 | ±0.3 | 0.007 |

| HD6-0600(red light) | 600 | 500 | 400 | 0.994 | 0.365 | ±0.4 | 0.008 |

| HD6-0800(red light) | 800 | 600 | 500 | 1. 269 | 0.408 | ±0.4 | 0.010 |

| HD6-1100(red light) | 1100 | 900 | 600 | 1.758 | 0.565 | ±0.4 | 0.013 |

| HD6-0050W(red light) | 50 | 140 | 60 | 0.08 | 0.04 | ±0.3 | 0.009 |

| HD6-0020W(Blu-ray) | 20 | 90 | 20 | 0.02 | 0.008 | ±0.2 | 0.002 |

| HD6-0022W(red light) | 22 | 140 | 30 | 0.03 | 0.012 | ±0.2 | 0.002 |

The white object refers to a laboratory standard block, and the measurement result refers to the average value of the Z-axis measured 64 times in repetition.

2.The concept of laser weld seam tracking technology

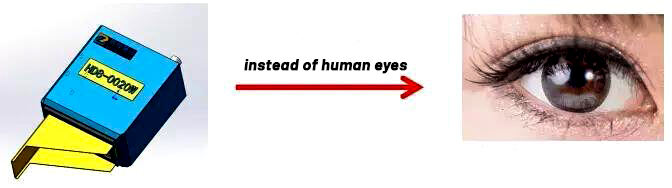

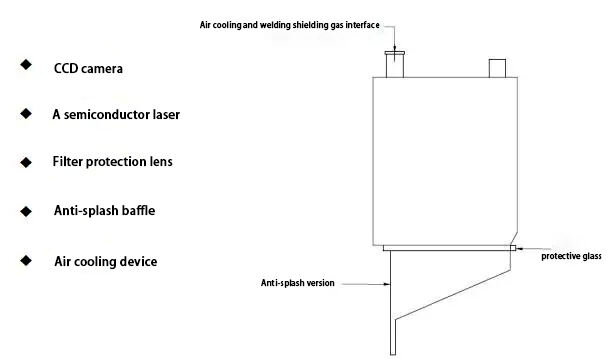

The seam tracking sensor mainly consists of a CCD camera, semiconductor laser, laser protection lens, anti-splash baffle, and air cooling device. It uses the principles of optical propagation and imaging to obtain the position information of each point within the laser scanning area, and uses complex program algorithms to complete real-time online detection of common weld seams.

For the detection range, detection capabilities, and common issues during the welding process, there are corresponding function settings. The sensor is usually installed in front of the welding gun at a predetermined distance (lead), so it can observe the distance from the seam sensor body to the workpiece, that is, the installation height depends on the installed sensor model. Only when the welding gun is correctly positioned above the seam can the camera see the seam.

The device calculates the deviation between the detected weld seam and the welding gun, outputs deviation data, and the motion executor corrects the deviation in real-time, guiding the welding gun for automatic welding. This process realizes real-time communication with the robot control system to track the weld seam for welding, which is equivalent to giving eyes to the robot.Manual or semi-automatic welding relies on the operator's naked eye observation and manual adjustments to track the weld seam.For fully automated welding applications, such as robots or automatic welding machines, they primarily rely on the machine's programming and memorization capabilities, as well as the precision and consistency of the workpiece and its assembly to ensure that the welding gun can aim at the weld seam within the precision range permitted by the process.Usually, the machine's repeat positioning accuracy, programming, and memory capabilities are sufficient to meet the requirements of welding.

However, in many cases, the precision and consistency of the workpiece and its assembly are not easy to meet the requirements of large-scale workpieces or large-scale automatic welding production. There is also the influence of stress and deformation caused by overheating.Therefore, when encountering these situations, an automatic tracking device is needed to perform functions similar to the coordinated tracking and adjustment of the eyes and hands in manual welding.

3.Components and functions of weld seam tracking sensors

CCD camera

The main function of the CCD camera in the welding seam tracking sensor is to read images. When shooting a scene with a CCD camera, the light reflected from the object is transmitted to the CCD through the lens of the CCD camera. After the CCD is exposed, the photodiode is excited by the light and releases a charge, and the electric signal of the photosensitive element is generated from this.

The CCD control chip uses the control signal lines in the photosensitive elements to control the current generated by the photodiodes, which is output by the current transmission circuit. The CCD camera collects the electrical signals generated by a single imaging process and outputs them collectively to the amplifier.The electric signal, after amplification and filtering, is sent to the A/D converter, which converts the electric signal (analog signal at this point) into a digital signal, and the value is directly proportional to the intensity of the electric signal, i.e., the voltage level. These values are essentially the data of the image.

However, the image data obtained in the previous step alone cannot directly generate an image. It needs to be output to the Digital Signal Processor (DSP).In the DSP, these image data undergo post-processing such as color correction, white balance treatment (depending on the user's settings in the CCD camera), and are encoded into data formats supported by the camera, such as image formats, resolution, etc., before they are saved as image files. Finally, the image files are written to the CCD camera's storage, either built-in or external.

A semiconductor laser

The laser is generated by a light source through a linear generator that produces power with uniform density, high linearity, and good stability, and outputs in a straight-line pattern. There are red and blue lasers to choose from, and the wavelength, angle, and line width can also be selected according to specific customer requirements.

Filter protection lenses

Due to the dust and spatter produced during the welding process, which can have an effect on data collection, a filter protection lens must be installed on each sensor. The filter protection lens serves to protect the laser camera on one hand, and to filter light on the other.When its surface is dirty, it should be replaced promptly. During the installation and replacement of the protective lens, any trace of adhesive, even a fingerprint or a drop of oil, will increase the absorption rate of the lens and reduce its service life.Therefore, the cleaning work of lenses cannot be ignored:

1) You must wear gloves during installation and do not leave any fingerprints;

2) Do not let anything scratch the surface of the lens;

3) When taking out the lens, hold the edge of the lens with your fingers and do not touch the film;

4) Use clean tissue paper, test paper and optical grade solvent to clean the lens.

Anti-splash baffle

It is mainly used to block the interference to the laser such as arc light splash, smoke and dust, so as to make the sensor system more accurate and stable in use.

Air cooling device

Due to the high temperatures during welding, most systems now use an air cooling system. This is done on one hand to cool down the sensor, and on the other hand to extend the sensor's service life.The protection level of the sensor casing is IP67, and the appropriate temperature for use is between 5°C and 45°C. Exceeding this temperature range will affect the service life of the sensor. If necessary, an additional water-cooled installation board can be used to cool the sensor head.

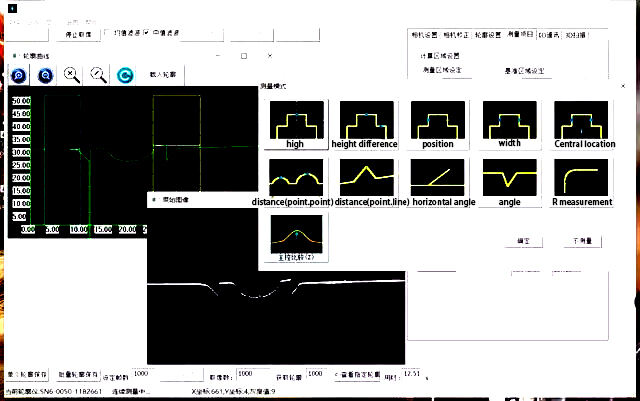

The sensor completes real-time online detection of common weld seams through complex program algorithms. There are appropriate function settings for the detection range, detection capabilities, and common issues encountered during the welding process.The device calculates the deviation between the detected weld seam and the welding gun, outputs deviation data, and the motion execution mechanism corrects the deviation in real time, accurately guiding the automatic welding of the welding gun, thereby achieving intelligent real-time tracking of the weld seam during the welding process.

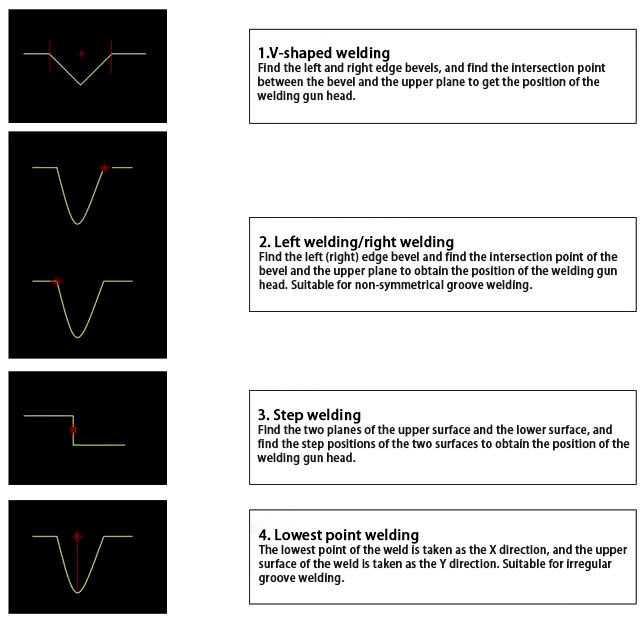

4.Welding type

Apply welding process:argon arc welding、laser welding、Laser hybrid welding、plasma arc welding、Carbon dioxide laser gas shielded welding、Submerged arc welding, etc.

Application areas:pressure vessel、car、shipbuilding、railway、structural steel、Container welding.

5.Development and Prospects

In the field of dedicated machines, seam trackers can meet various environmental needs, such as welding the inner lining of water heaters, welding air compressor storage tanks, and tracking lines on steel cylinders, etc. Imported brands mainly excel at tracking small diameter pipes, but for long straight lines and circular lines, the technology differences between domestic and imported models is minor. However, the cost is only one third to half of that of imports, making the market prospects attractive.

With the development of advanced manufacturing technology, realizing the automation and intelligence of welding tracking has become an inevitable trend. In the next few years, laser seam tracking will not only need technological upgrades, but also need to understand customer applications deeply in order to meet user needs and improve products in terms of application expansion.