1.Laser thermal conductivity welding definition and characteristics Laser thermal conductivity welding is a method of laser welding. This welding mode has shallow penetration depth and small depth-to-width ratio.When the power density is less th...

Contact Us

1.Laser thermal conductivity welding definition and characteristics

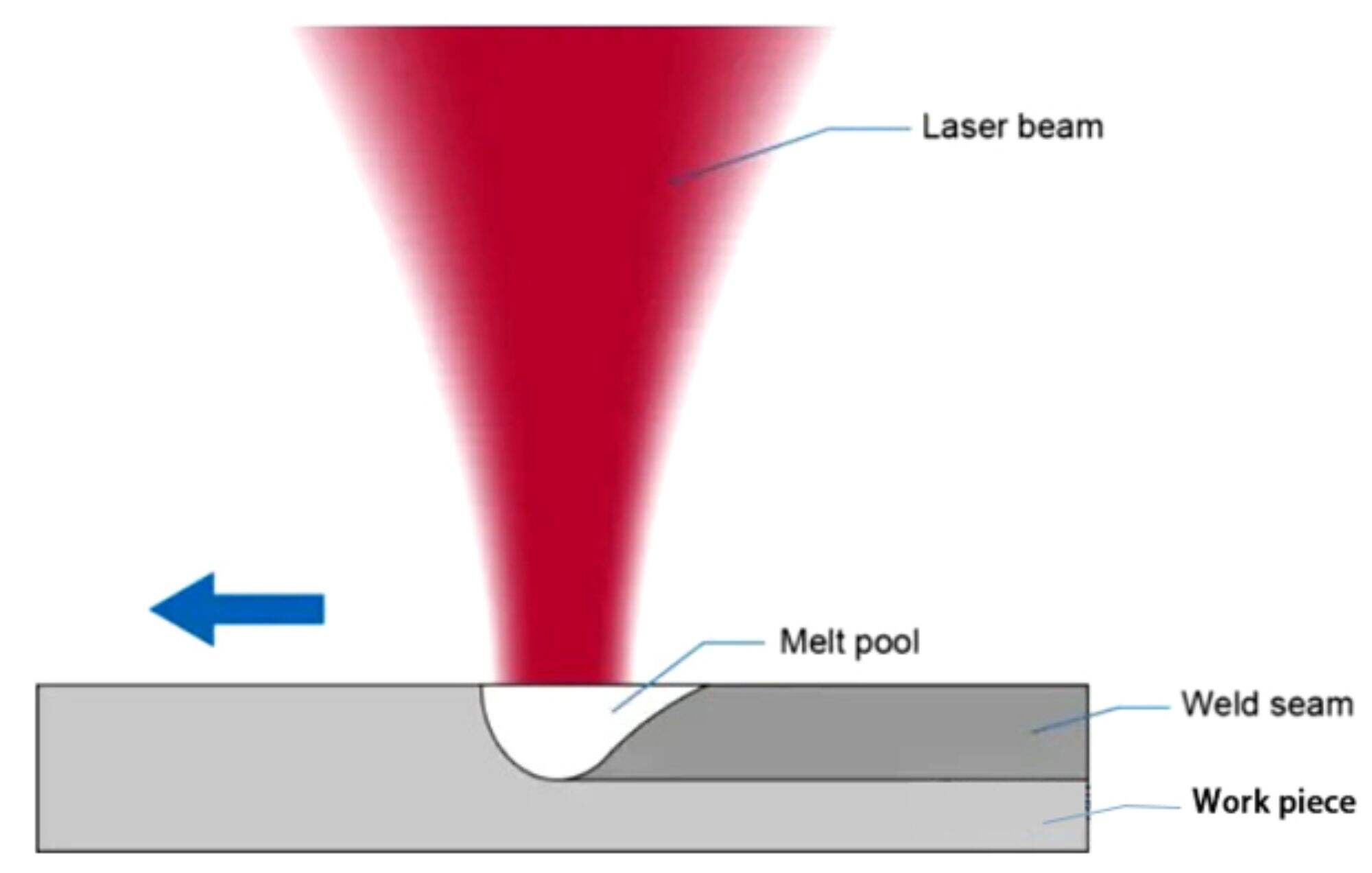

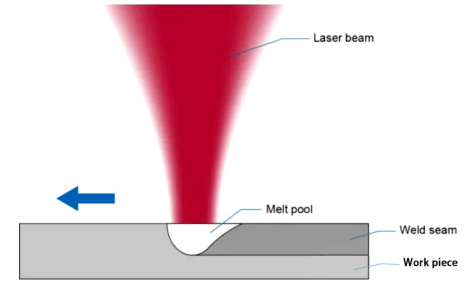

Laser thermal conductivity welding is a method of laser welding. This welding mode has shallow penetration depth and small depth-to-width ratio.When the power density is less than 10^4~10^5 W/cm2, it is classified as conduction welding, which is characterized by its shallow depth of fusion and slower welding speed.

During thermal conduction welding, laser radiation energy acts on the surface of the material, and the laser radiation energy is converted into heat on the surface.The surface heat diffuses to the interior through thermal conduction, causing the material to melt and forming a molten pool in the link area between the two materials.The molten pool moves forward along with the laser beam, and the molten metal in the molten pool does not move forward.As the laser beam moves forward, the molten metal in the molten pool solidifies, forming a weld connecting the two pieces of material.

Laser radiation energy only acts on the surface of the material, and the melting of the underlying material is carried out by heat conduction.After the laser energy is absorbed by the thin layer of 10~100nm on the surface and melted, the surface temperature continues to increase, causing the isotherm of the melting temperature to propagate deep into the material.The maximum surface temperature can only reach the vaporization temperature.Therefore, the melting depth that can be achieved with this method is limited by the vaporization temperature and thermal conductivity. It is mainly used for welding thin (about 1mm) and small parts.

The power density of the beam used in welding is low. After the workpiece absorbs the laser, the temperature only needs to reach the surface melting point, and then heat is transferred to the interior of the workpiece to form a molten pool by thermal conduction, so it is economical.In addition, the weld seam is smooth and has no pores, and can be used for welding processing of appearance parts.

Typical applications are stainless steel sink welding, metal bellows, metal pipe fittings welding, etc.

2.Laser deep penetration welding definition and characteristics

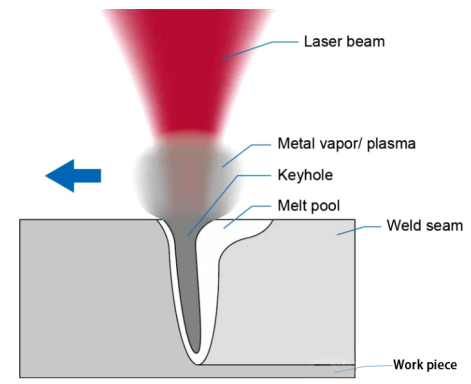

When the power density is greater than 10^5~10^7 W/cm2, the metal surface is concave into "holes" due to heat, forming deep penetration welding, which has the characteristics of fast welding speed and large aspect ratio.

The metallurgical physical process of laser deep penetration welding is very similar to that of electron beam welding, that is, the energy conversion mechanism is completed through the "small hole" structure.Under irradiation with a high enough power density beam, the material evaporates to form small holes.This small hole filled with steam is like a black body, absorbing almost all the energy of the incident light, and the equilibrium temperature in the hole reaches about 25,000 degrees.Heat is transferred from the outer wall of this high-temperature cavity, causing the metal surrounding the cavity to melt.The small hole is filled with high-temperature steam generated by the continuous evaporation of the wall material under the irradiation of the beam. The walls of the small hole are surrounded by molten metal, and the liquid metal is surrounded by solid materials.The liquid flow outside the hole wall and the surface tension of the wall layer are in phase with the continuously generated steam pressure in the hole cavity and maintain a dynamic balance.The light beam continuously enters the small hole, and the material outside the small hole is continuously flowing. As the light beam moves, the small hole is always in a stable state of flow. That is to say, the small hole and the molten metal surrounding the hole wall move forward with the forward speed of the pilot beam. The molten metal fills the gap left after the small hole is removed and condenses accordingly, and the weld is formed.All of this happens so quickly that welding speeds can easily reach several meters per minute.

Deep penetration welding of materials requires very high laser power.Different from heat conduction welding, deep penetration welding not only melts the metal, but also vaporizes the metal.The molten metal is discharged under the pressure of metal vapor to form small holes. The laser beam continues to illuminate the lower part of the hole, causing the hole to extend until the vapor pressure inside the hole balances with the surface tension and gravity of the liquid metal.After deep penetration welding, a narrow and uniform weld will be formed, and its depth will generally be greater than the width of the weld.This process has the characteristics of fast processing speed and small heat-affected zone, so the material deformation is small.

Typical applications are the welding of thick steel plates (10-25mm) and the welding of power battery aluminum shells.

3.Characteristics of laser deep penetration welding

High aspect ratio. Because molten metal forms around a cylindrical chamber of high-temperature vapor and extends toward the workpiece, the weld becomes deep and narrow.

Minimum heat input. Because the temperature inside the small hole is very high, the melting process occurs extremely quickly, the heat input to the workpiece is very low, and the thermal deformation and heat-affected zone are small.

High density. Because the small holes filled with high-temperature vapor are conducive to the stirring of the welding pool and the escape of gas, resulting in a penetration weld without pores. The high cooling rate after welding can easily refine the weld structure.

Strong welds. Because of the hot heat source and the full absorption of non-metallic components, the impurity content is reduced, the inclusion size and its distribution in the molten pool are changed.The welding process does not require electrodes or filler wires, and the melting zone is less contaminated, making the strength and toughness of the weld at least equal to or even exceeding that of the parent metal.

Precise control. Because the focused light spot is small, the weld seam can be positioned with high precision.The laser output has no "inertia" and can be stopped and restarted at high speeds. Complex workpieces can be welded using CNC beam movement technology.

Non-contact atmospheric welding process.Because the energy comes from the photon beam and there is no physical contact with the workpiece, no external force is exerted on the workpiece. In addition, magnetism and air have no effect on laser light.

Advantages of laser deep penetration welding:

1)Because focused laser has a much higher power density than conventional methods, it results in fast welding speed, small heat-affected zone and small deformation, and can also weld difficult-to-weld materials such as titanium.

2)Because the beam is easy to transmit and control, there is no need to frequently replace welding guns and nozzles, and there is no vacuum required for electron beam welding, which significantly reduces downtime and auxiliary time, so the load factor and production efficiency are high.

3)Due to the purification effect and high cooling rate, the weld seam has high strength,toughness and overall performance.

4)Due to the low average heat input and high processing accuracy, reprocessing costs can be reduced; in addition, laser welding operating costs are also low, which can reduce workpiece processing costs.

5)It can effectively control the beam intensity and fine positioning, and it is easy to realize automatic operation.

Disadvantages of laser deep penetration welding:

1)The welding depth is limited.

2)The workpiece assembly requires high requirements.

3)The one-time investment in the laser system is relatively high