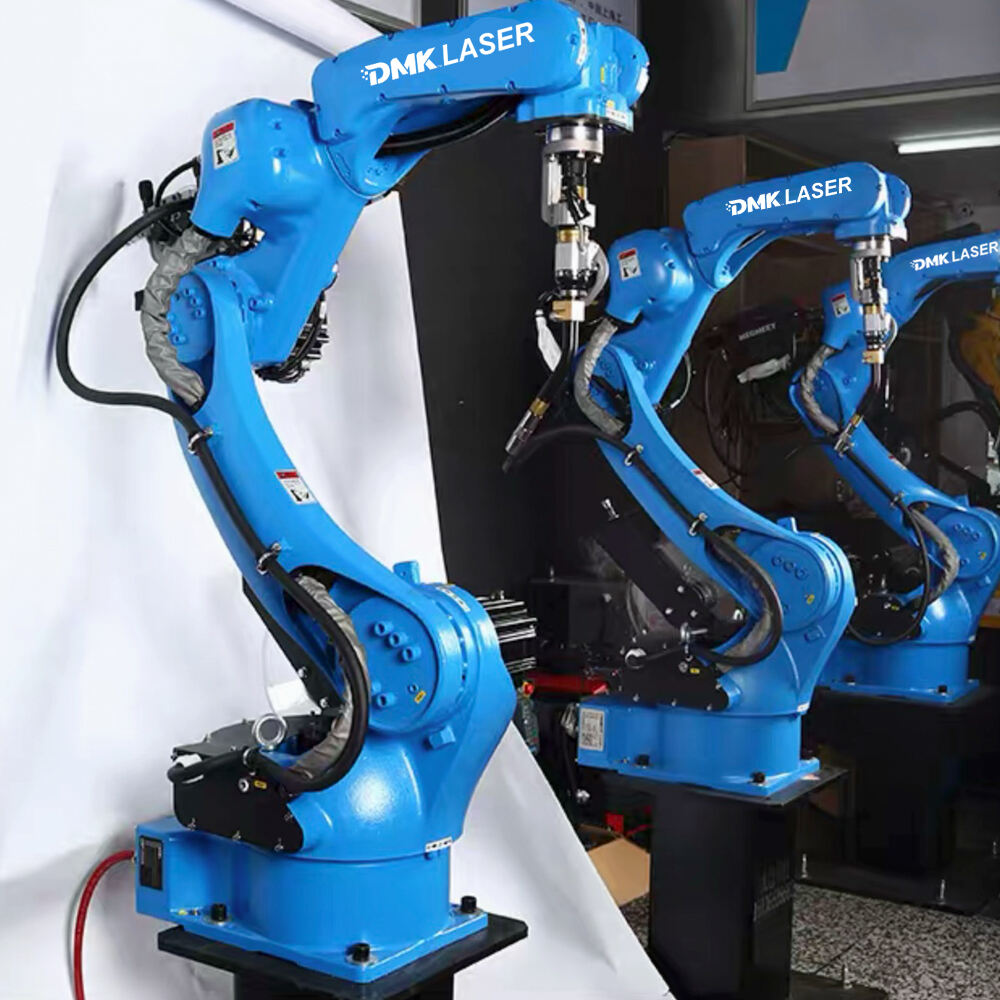

Yaskawa Six-Axis Industrial Welding Robot for Automated Welding

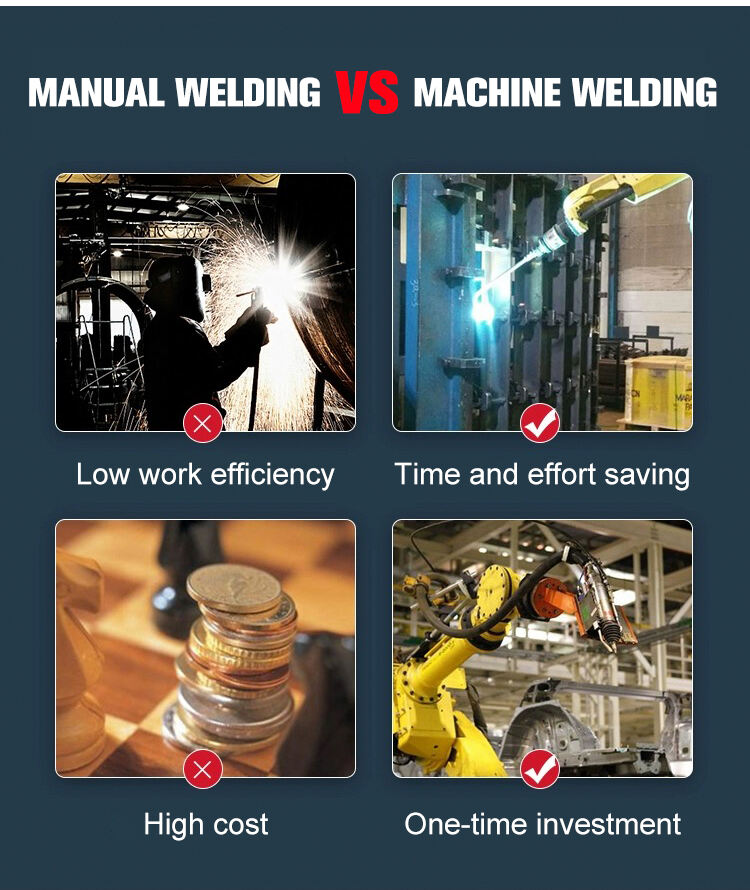

Product Description

Digital Communication

Ethernet-based digital communication with the robot ensures seamless integration.

Ultra-Low Spatter

Through precise control of the entire welding cycle, from arc ignition to droplet formation and bridge breakage, ultra-low spatter is achieved, reducing spatter by up to 90% compared to standard digital welding power sources.

Contact Lift-Arc Ignition

New contact lift-arc ignition technology reduces spatter during arc start and increases arc ignition success rate.

Constant Arc Length Control

High-speed digital inverter control rapidly adjusts arc and voltage, ensuring stable welding performance across a wide voltage range.

Easy Operation

With one-touch adjustments, the arc shape can be freely customized, making it easy to meet different welding requirements.

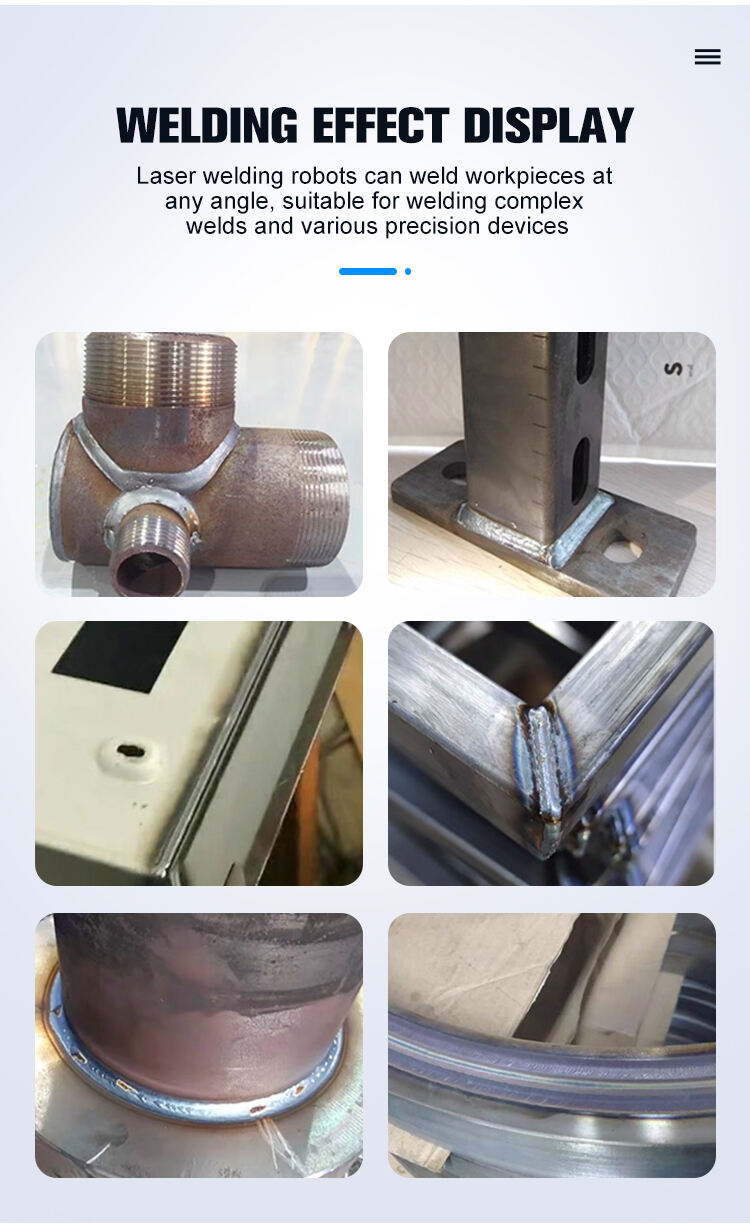

Suitable for Various Materials

Equipped with an extensive welding expert database, this system supports pulse and short-circuit welding for materials like carbon steel, stainless steel, galvanized sheets, and aluminum alloys. It is especially ideal for thin sheet applications in industries such as furniture, metal fabrication, and electric vehicles.

Standard Specifications

| Structure | Vertical multi-joint type (6 degrees of freedom) | |

| Moveable mass*1 | Head of hand | 180kg |

| U arm | 30kg | |

| Up to max. | 2702 mm | |

| Repeat positioning accuracy*2 | 0.05mm | |

| Body weight | 1020kg | |

| Protection Grade | Body:IP54,Wrist shaft:IP67 | |

| Installation | Floor-mounted | |

For More Details

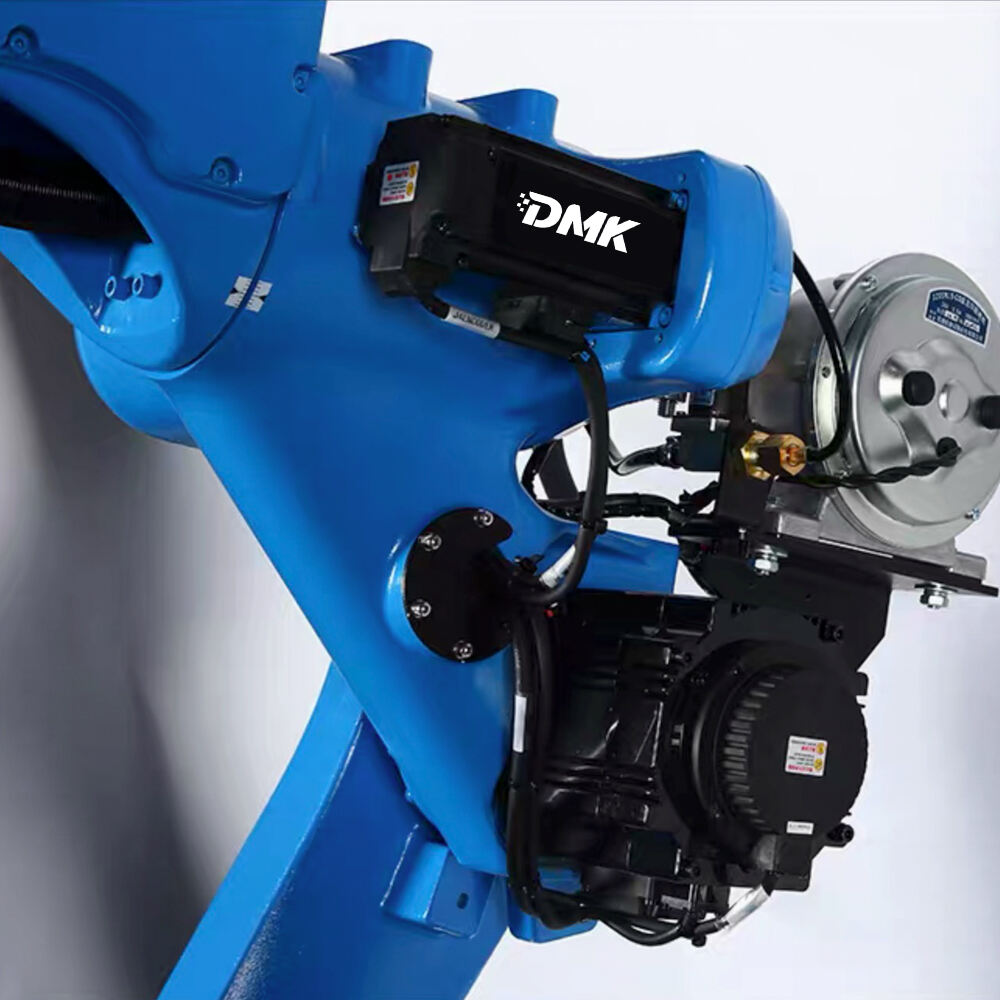

Servo Welding Torch

Built-in servo welding torch enables high-speed welding with ultra-low spatter, improving positional accuracy and offering greater operational flexibility.

Water-Cooling Design

The integrated water-cooling system for the torch neck and motor significantly enhances usage efficiency and durability.

Precise and Stable Wire Feeding

The torque-assisted wire feeding mechanism ensures synchronized forward and backward feeding, delivering smooth and powerful wire supply.

Advanced Sensing Technology

Optional advanced sensing technologies include contact sensing, laser seam detection, arc tracking, and laser tracking.

6-Axis Articulated Design

The arm is designed to minimize interference with surrounding equipment, saving valuable workspace.

Constant Arc Length Control

Fully digital inverter control rapidly adjusts arc voltage, ensuring stability throughout the welding process.

Appliance

Widely used in arc welding, laser processing, handling, automotive industry, hardware and machinery industry;

Usage:Handling assembly/distribution; can meet the needs of a wide range of users such as bulk parts gripping, nesting, assembling, hitting, processing pickup/packaging, palletising, etc.

Company Profile

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR