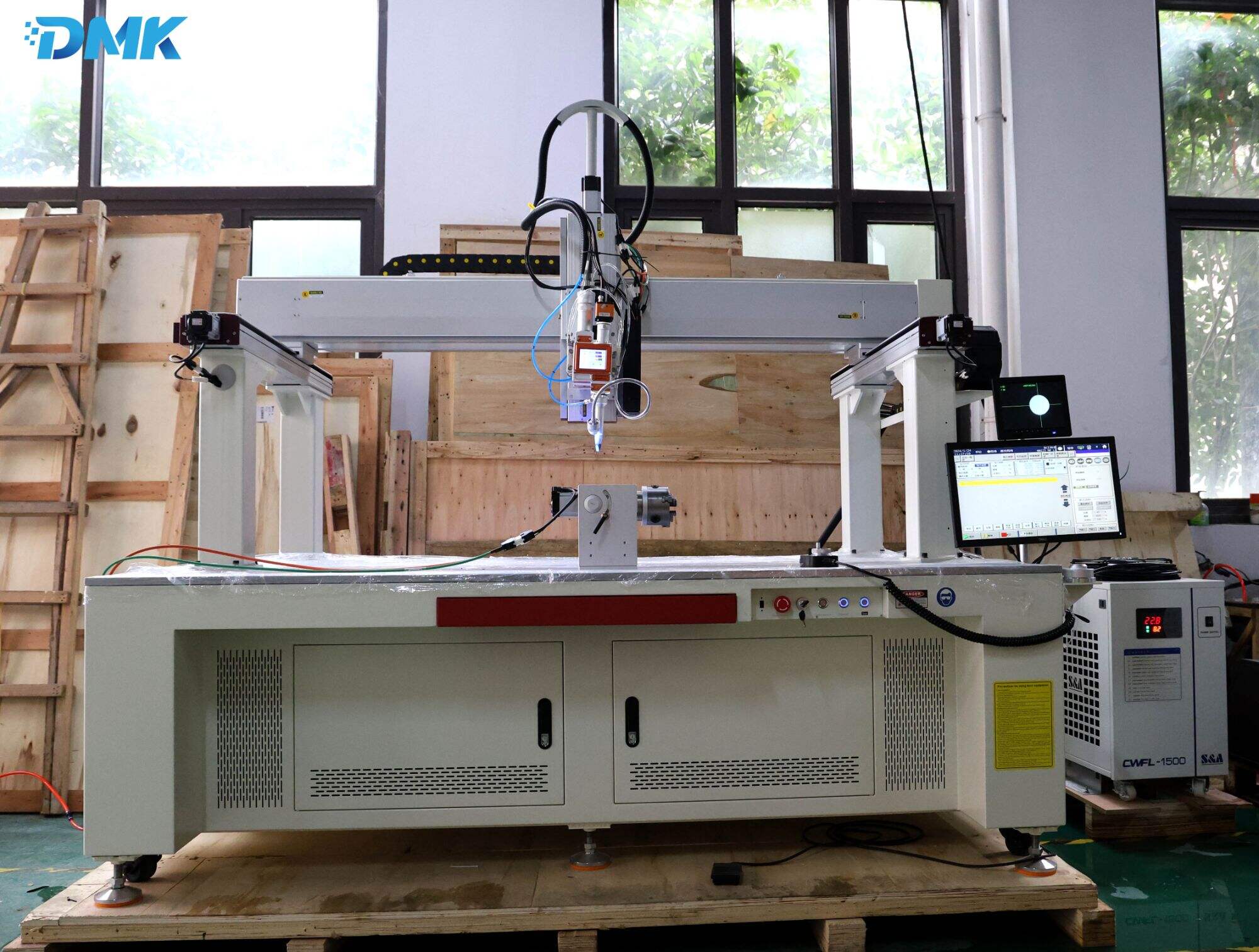

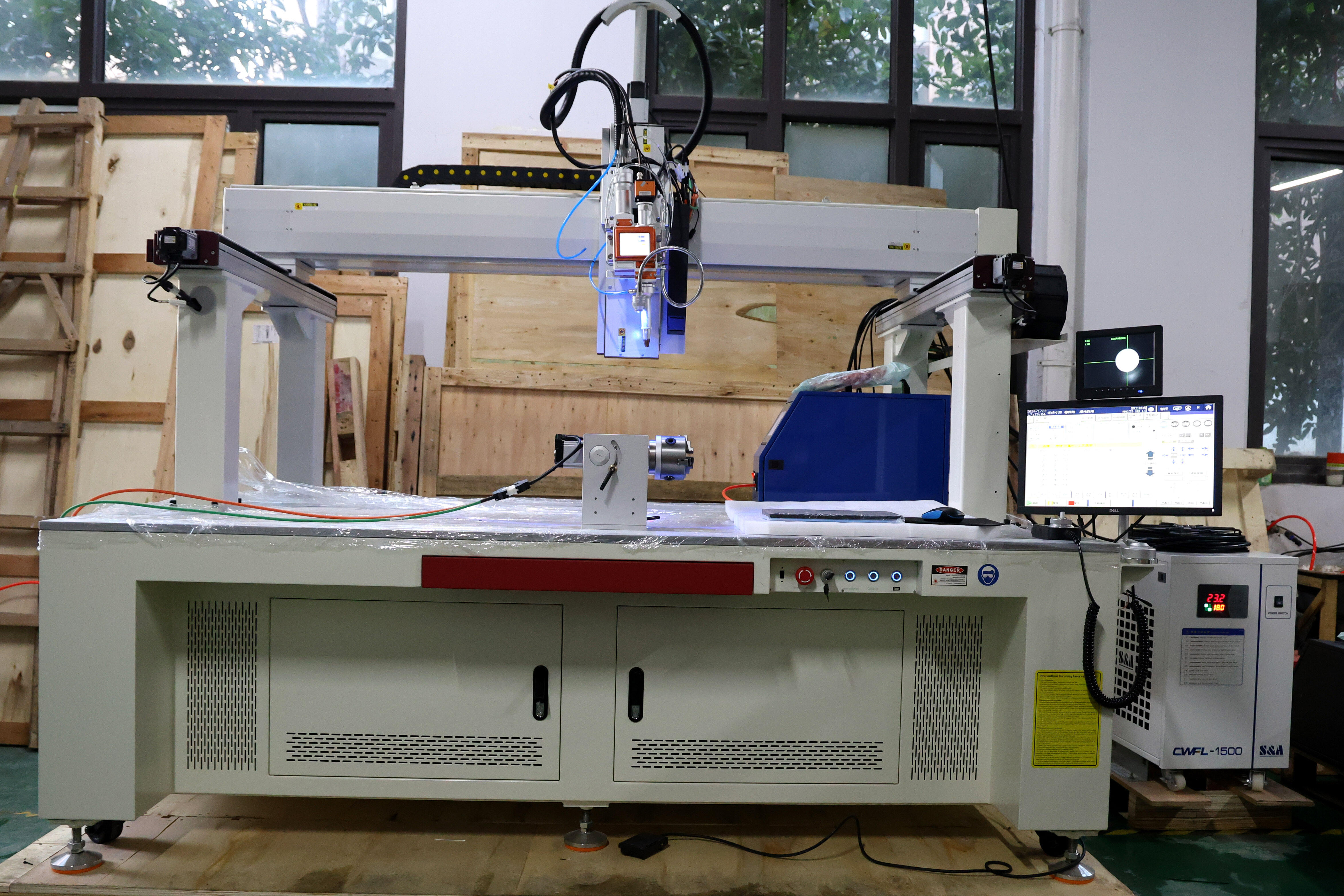

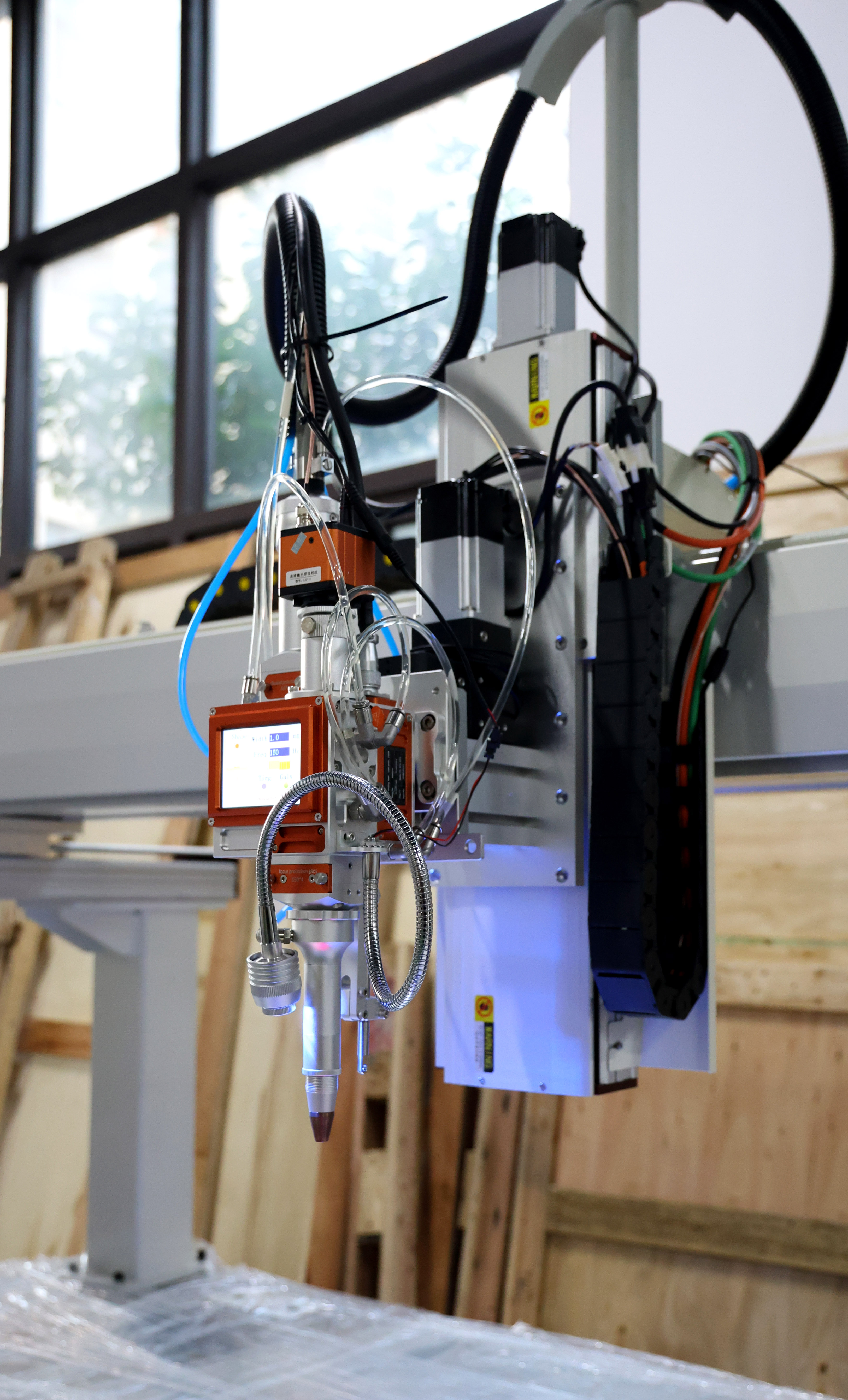

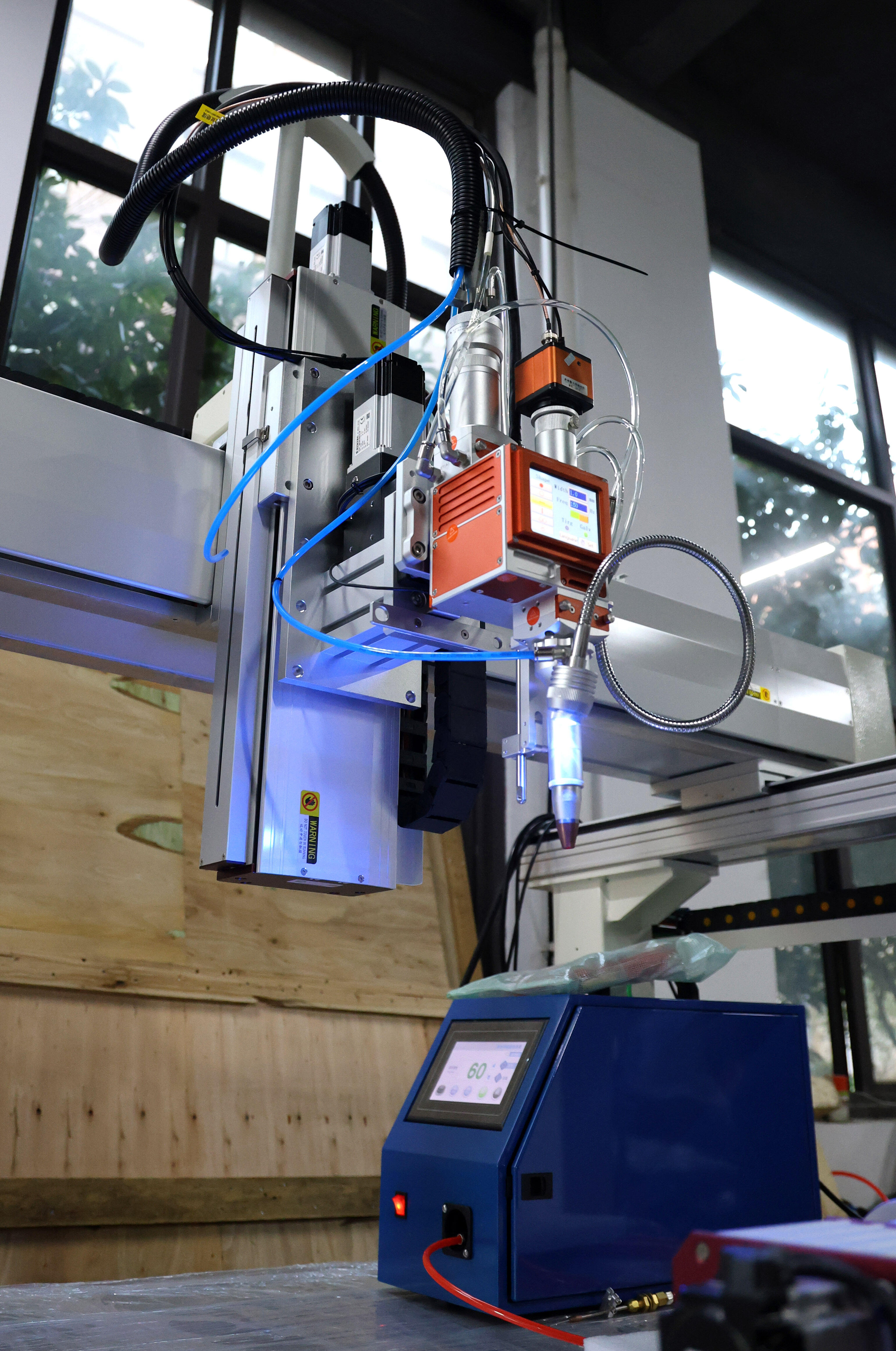

Gantry Double Drive Fiber Laser Welding Machine

| Product Description |

Automatic Platform 3 Axis 4 Axis 5 Axis Fiber Laser Welding MachineEquipped with a CCD monitoring system and advanced control software, the fiber laser welder makes accurate positioning, auto-focuses on the welding parts, and produces high-tensile tight seams with top visual quality. With fixtures and rotating devices, you gain a boosted welding efficiency by quickly welding similar products in large quantities and with high consistency.

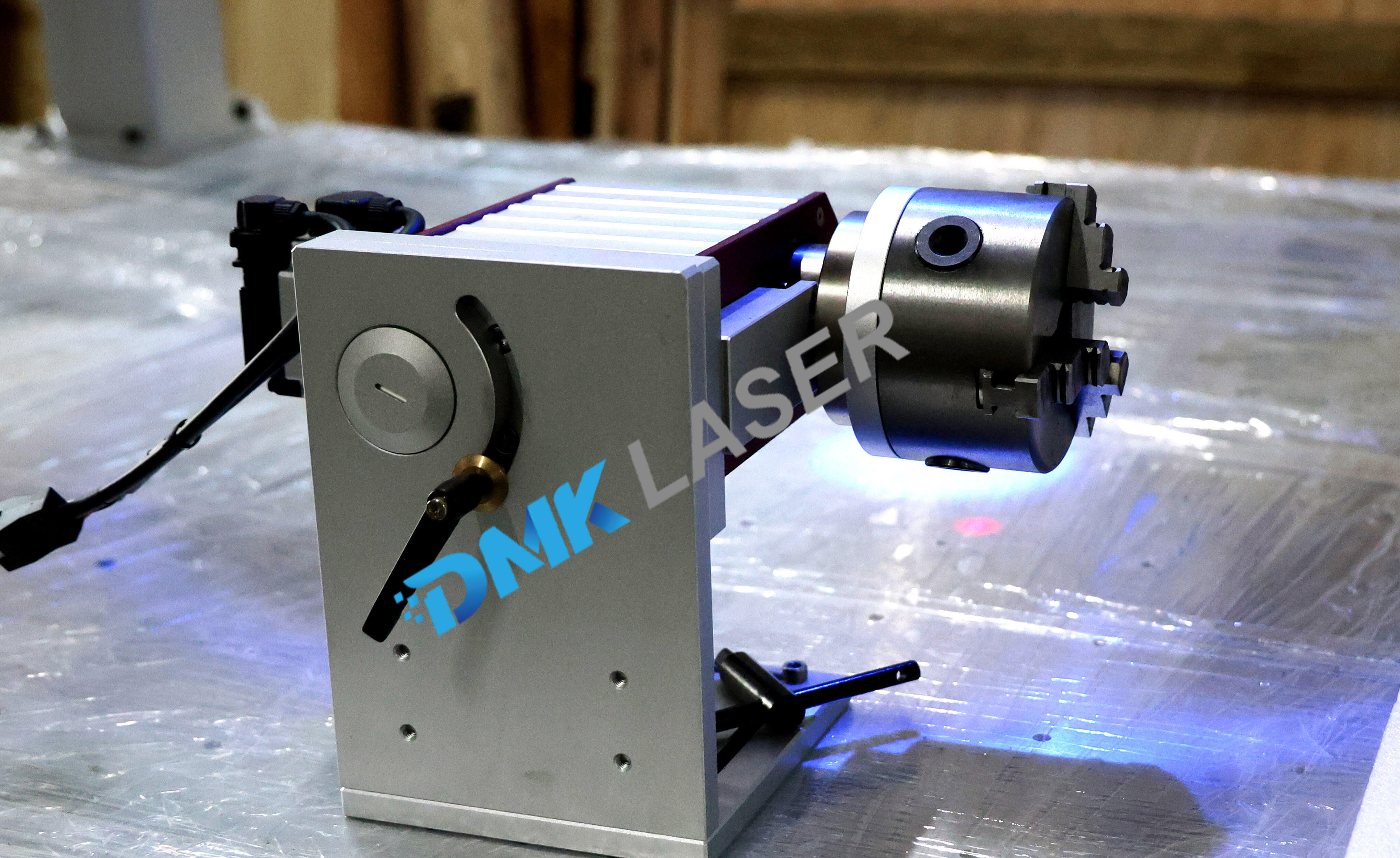

1. It get more design freedom to create various seam shapes. 2. X, Y, Z electric three-axis stroke 400*300*300, it can reach repeat positioning accuracy ±0.05. 3. Optional laser generator, such as YAG, QCW high-speed splitter, fiber laser, semiconductor, etc. 4. Exclusive models can be customized according to customer needs, and two rotating shafts can be added. |

|

|

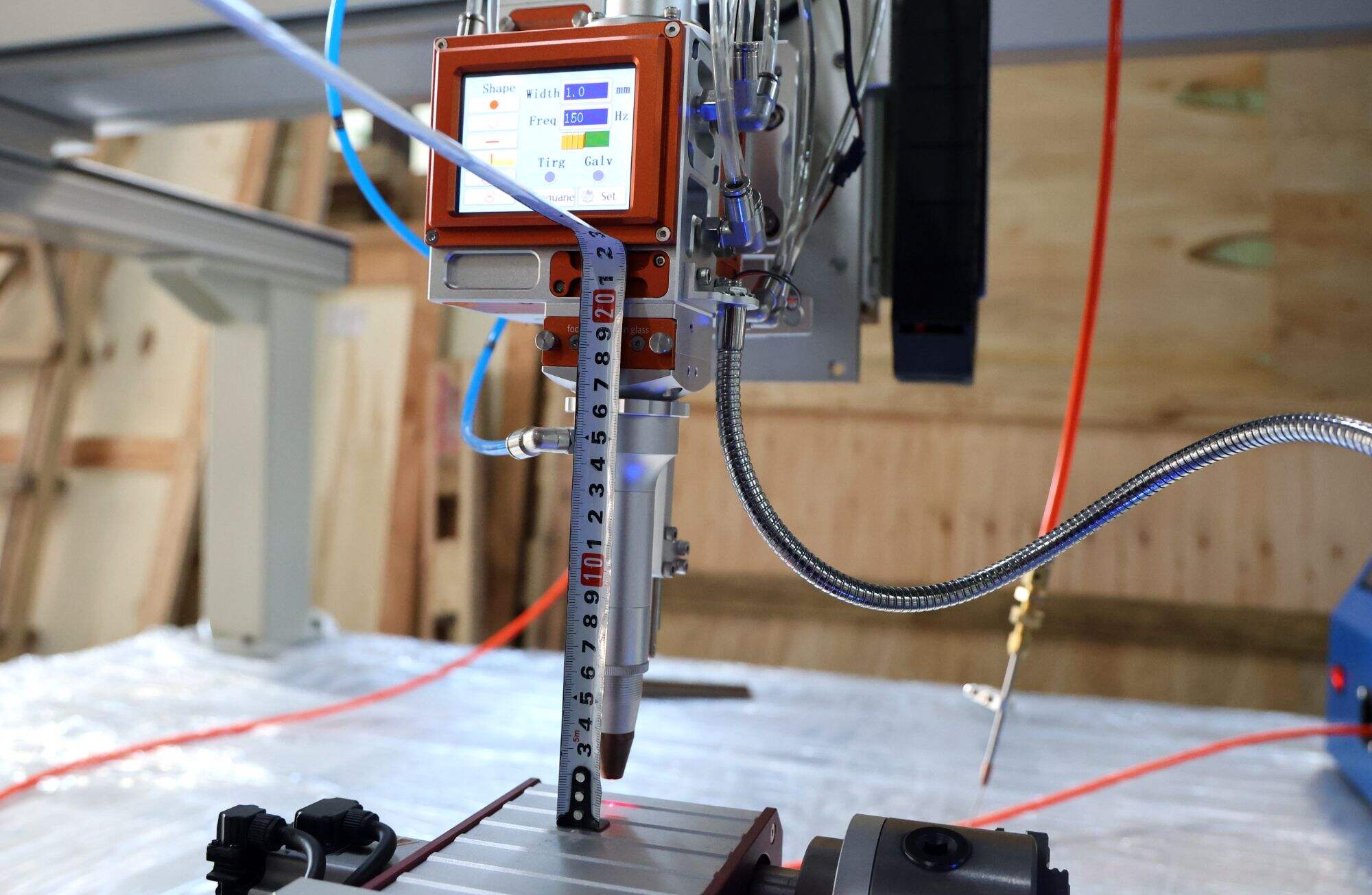

"HW20 Double Pendulum Galvo"lt is a dual-axis swing welding headindependently developed by our company. The welding head consists of a QBHcollimation module, a dual-axis galvanometer assembly, a focusing module and aCCD monitoring module.The internal integrated galvanometer controller and driver, the galvanometerfrequency is 200Hz, and the spot width is 0-5mm. |

| Product Feature |

|

|

| Parameter |

| Product Name | Galvo Scanner Laser Welding Machine |

| Laser Power | 1KW 1.5KW 2KW 3KW 5KW optional |

| Laser Wavelength | 1070nm |

| Pulse Width | 0.5-20ms |

| Pulse Frequency | ≤100Hz |

| Spot Diameter | 0.1-3mm |

| Repeat Accuracy | ±0.01mm |

| Machine Voltage | AC220V/380V 50-60Hz 3-Phase |

| Cooling System | Water Cooling |

| Details lmages |

|

laser source |

laser chiller |

|

Custom Fixture |

Special Welding Software |

| Application |

|

Applications of lithium battery welding machines include:

|

| Company Profile |

Demark (Wuhan) Technology Co., Ltd is a high-tech enterprise focusing on the research and development, production, sales and service of fiber laser equipment. It is headquartered in Wuhan Optics Valley, the birthplace of laser technology in China. Relying on the solid scientific research strength of Huazhong University of Science and Technology, the company has mastered a number of core technologies in laser cutting, welding, cleaning and marking through more than 20 years of exploration and accumulation, and has more than 60 patent protections.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR