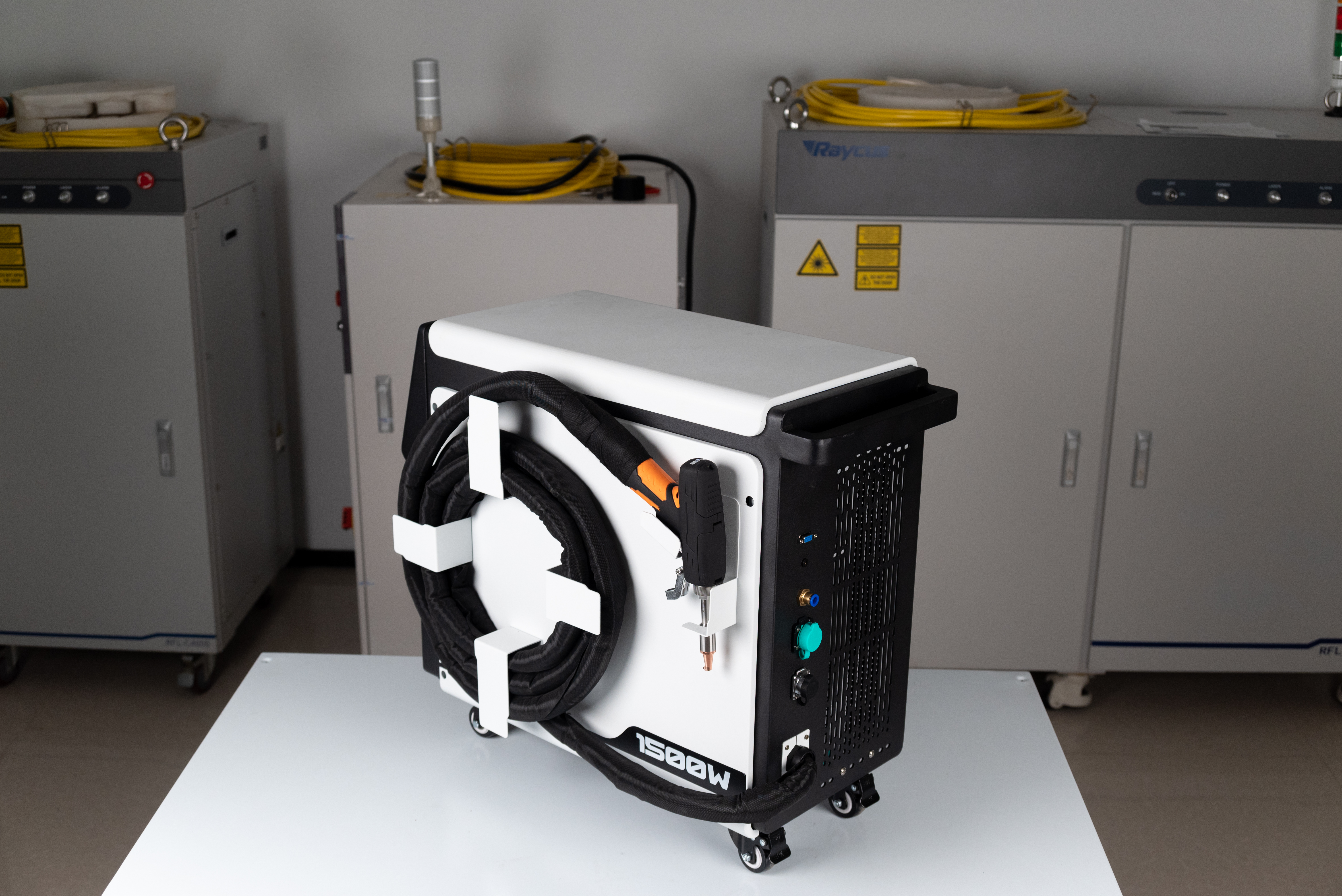

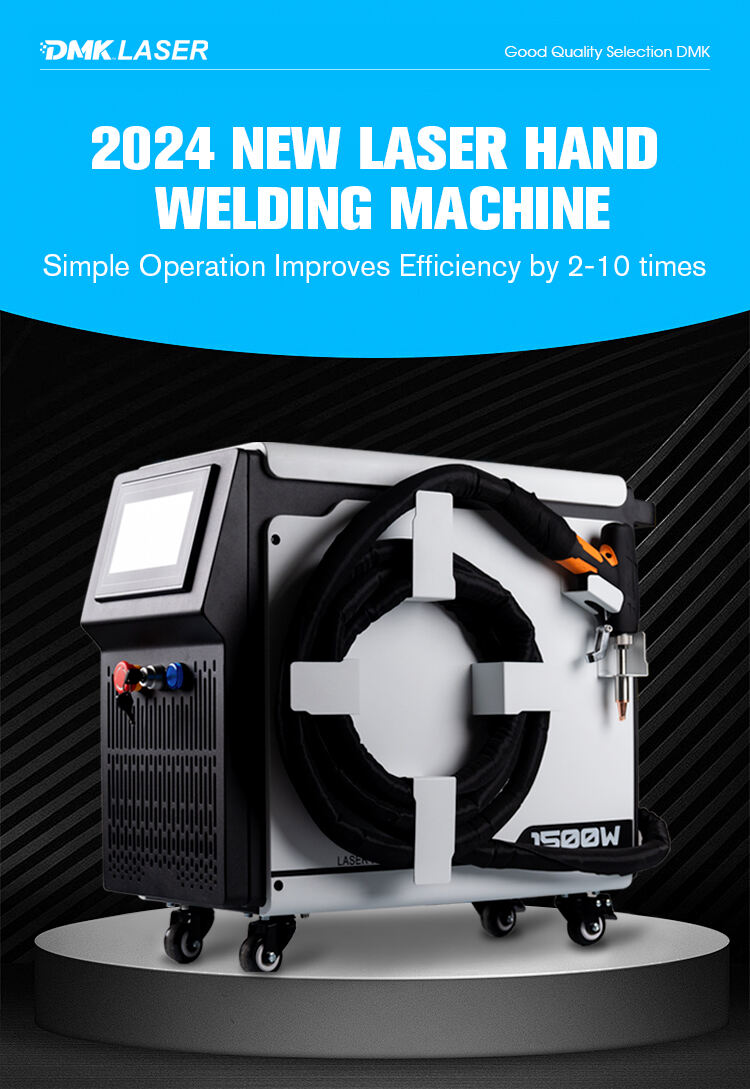

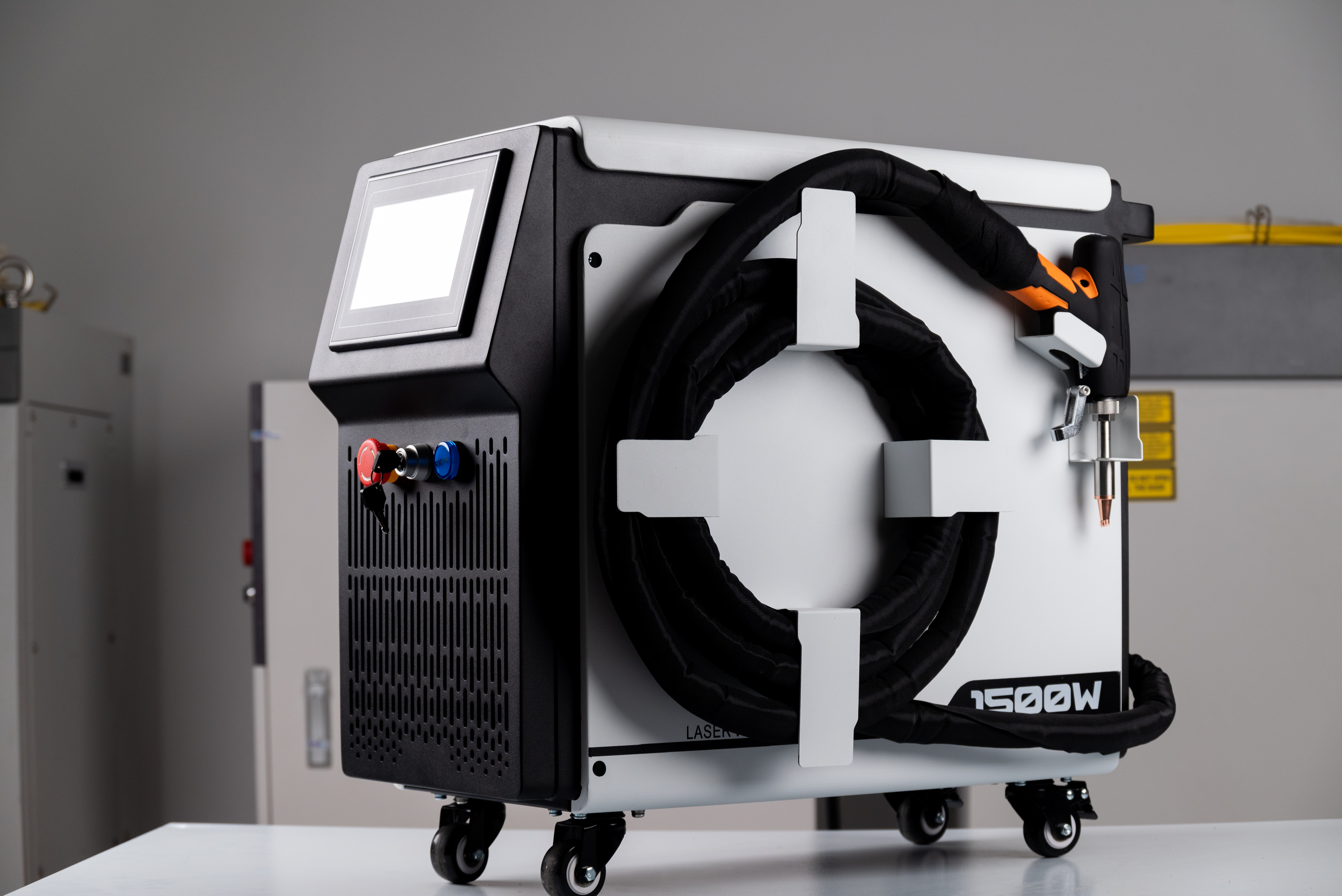

DMK 1500W Air-cooling Portable Handheld Fiber Laser Welding Machine

| Product Description |

The "fiber continuous laser handheld welding machine" consists of an integrated cabinet, fiber laser, laser control system and handheld welding head. This product is widely used in metal advertising word welding, stainless steel engineering welding, sheet metal cabinet welding and large sheet metal structure welding.

| Product Features |

|

Easy to move The volume of the whole machine is less than 0.1m³, and the weight is light: 54Kg. Easy to hold The welding torch head is small in size, all aluminum alloy body, light in weight. Precise and stable The laser control system is precise, the beam is stable, and the weld quality is consistent. |

|

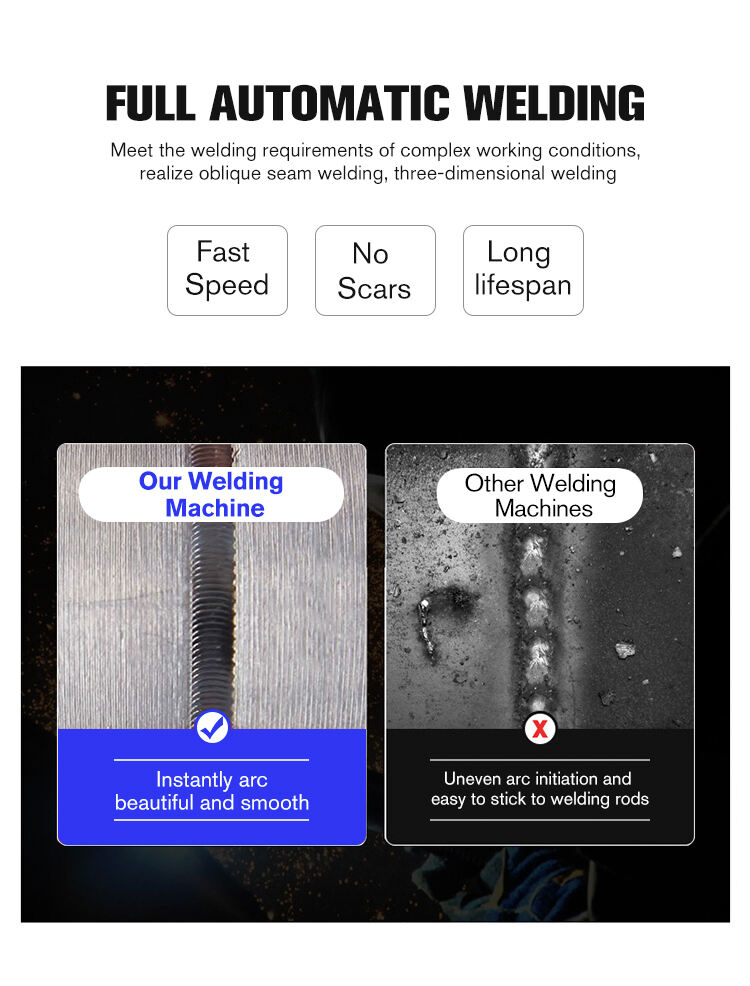

Welding speed is fast The weld is smooth and beautiful No welding work deformation |

|

|

|

Patent appearance Unique appearance patent design, magnesium aluminum alloy shell, good toughness and high strength. Simple storage

Patented design for quick storage of armored cables and welding torch tips. Easy maintenance

Integrated design, easy maintenance. |

| Production Specification |

|

Model |

KW-80FL |

KW-15FL |

KW-15FT |

KW-20FT |

|

Laser power |

750W |

1200W |

1500 |

2000 |

|

Working mode |

Continuous or modulate |

|||

|

Laser wavelength |

1064NM |

|||

|

Beam quality |

M2<1.1 |

M2<1.2 |

M2<1.2 |

M2<1.2 |

|

|

|

|

|

|

|

Power supply |

AC220V±5% 50/60Hz 10A |

AC220V±5% 50/60Hz 16A |

AC220V±5% 50/60Hz 16A |

AC220V±5% 50/60Hz 20A |

|

Power |

≤2300W |

≤3000W |

≤3500W |

≤4500W |

|

Cooling system |

Air-cooling |

|||

|

Fiber length |

Customizable |

|||

|

Temperature range of working environment |

0~38 ℃ |

|||

|

Applicable materials

|

Carbon steel、stainless steel、galvanized sheet, etc |

|||

|

Welding thickness range |

MAX2mm |

MAX3mm |

MAX4mm |

MAX4mm |

|

Weld requirements |

<0.5mm |

|||

| Product Details |

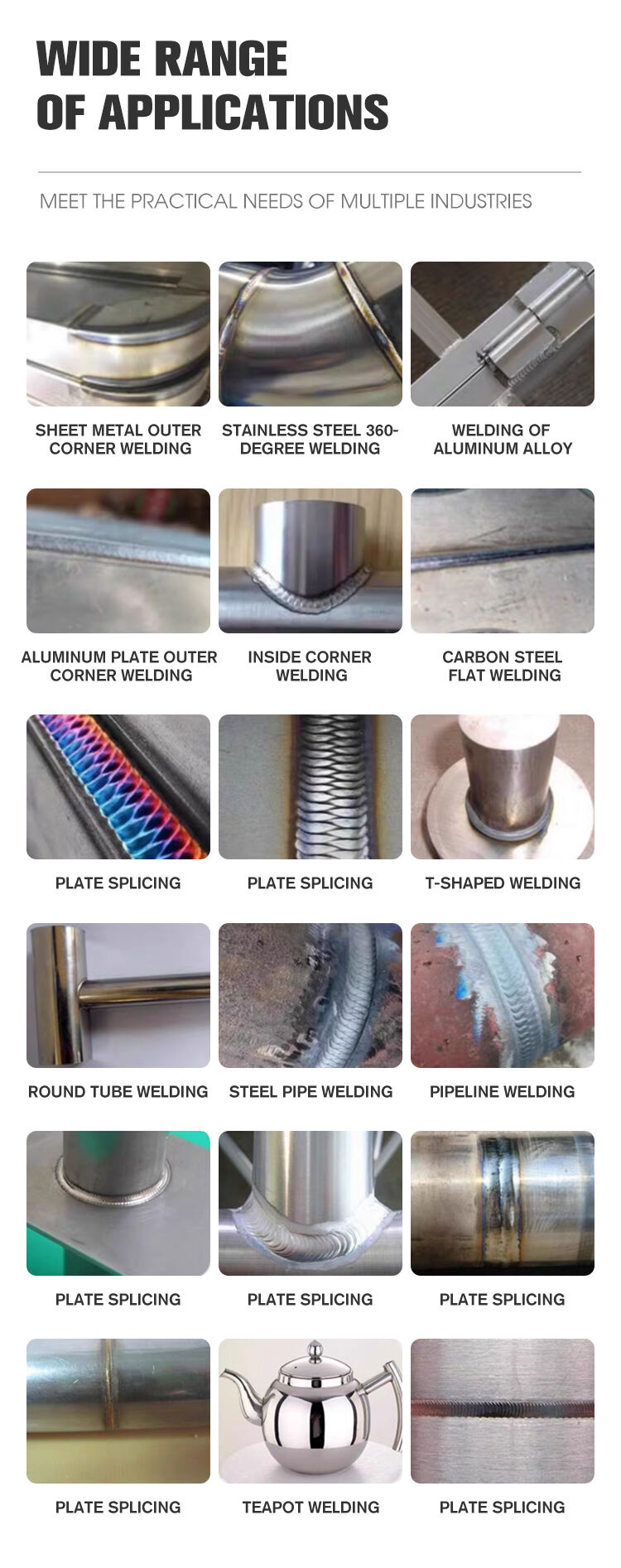

| Product Applications |

Wide range of welding materials: carbon steel, stainless steel, aluminum alloy, brass, copper, pickling sheet, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy and other metal materials.

| Package |

|

|

|

|

Features Of Our Company’s Product Transportation Packaging:

1)Protection: The Main Function Of Packaging Is To Protect The Product From Damage During Transportation. This Includes Shipping Products Around The World By Truck, Sea Or Air.

2)Security: Packaging Can Also Include Security Features Such As Seals Or Shrink Wrap To Prevent Tampering And Theft.

3)Compliance: International Shipping Must Comply With Different Regulations, And Packaging Often Needs To Reflect These Compliances. This Can Include Specific Labels And Documentation Attached To The Packaging.

4)Environmental Protection: As People's Awareness Of Sustainable Development Continues To Increase, It Is Important To Consider Environmentally Friendly Packaging Solutions.

FAQ

FAQ

Q: What are the advantages of using a handheld laser welding machine?

A: Some of the advantages of using a handheld laser welding machine include precision, speed, and flexibility. The machine can weld materials that are difficult or impossible to weld with traditional welding methods, and it produces a high-quality weld with minimal distortion.

Q: What types of materials can be welded with a handheld laser welding machine?

A: Handheld laser welding machines can be used to weld a variety of materials, including stainless steel, aluminum, copper, brass, and titanium. They can also be used to weld dissimilar materials, such as steel and aluminum.

Q: What are some applications of handheld laser welding machines?

A: Handheld laser welding machines are used in a wide range of industries, including automotive, aerospace, medical, and jewelry. They can be used to weld components for engines, transmissions, and other mechanical parts, as well as to repair or modify existing parts.

Q: Are handheld laser welding machines safe to use?

A: Yes, handheld laser welding machines are generally safe to use when operated properly. However, it is important to follow safety guidelines and wear appropriate protective gear, such as goggles or a face shield, when using the machine.

Q: What is the cost of a handheld laser welding machine?

A: The cost of a handheld laser welding machine can vary depending on the manufacturer, model, and features. Generally, they can range from several thousand dollars to tens of thousands of dollars.

Q: Do handheld laser welding machines require special training to operate?

A: Yes, operating a handheld laser welding machine requires special training and certification. This is because of the high-powered laser beam used by the machine, which can be dangerous if not handled properly. Training programs are offered by manufacturers and industry organizations.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR