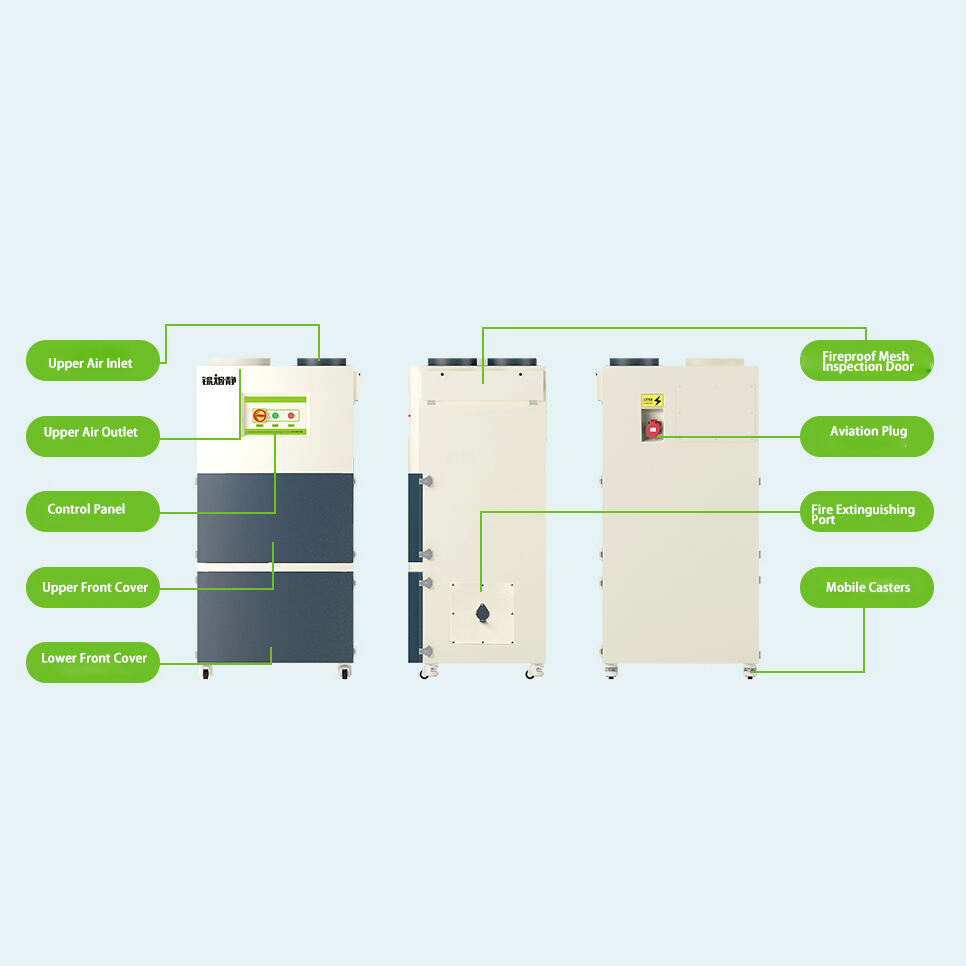

XS1500-10 Laser Fume Extractor

| Product Description |

High-Efficiency Fume Extraction for Laser and Soldering Applications

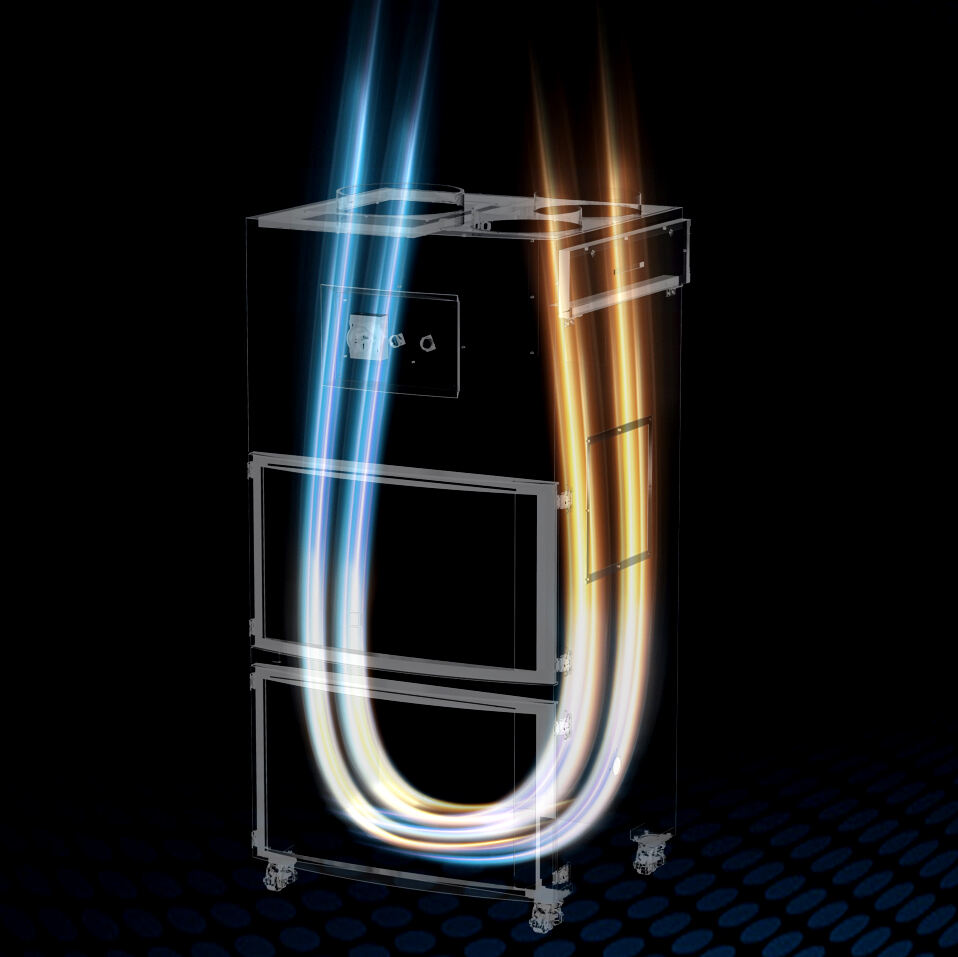

The XS1500-10 is a high-performance fume extractor designed to effectively remove harmful smoke, dust, and odors generated during various industrial processes. Its robust filtration system ensures a cleaner and safer working environment.

| Key Features |

Versatile Application: Ideal for wave soldering, reflow soldering, laser welding, and laser cutting operations.

Advanced Filtration System: Equipped with a multi-stage filtration system, including pre-filters, HEPA filters, and activated carbon filters, achieving a purification efficiency of up to 99.97% for particles as small as 0.3 microns.

High Airflow Capacity: Delivers a substantial airflow rate to effectively capture and filter fumes and particulates.

Energy-Efficient Operation: Designed for low power consumption without compromising performance.

Quiet Performance: Operates at low noise levels, ensuring a comfortable working environment.

User-Friendly Design: Features a compact and mobile design with easy-to-use controls for convenient operation and maintenance.

| Technical Specifications |

| Model | XS1500-10 | XS2000-12 |

|---|---|---|

| Number of Filter Layers | 3 | 4 |

| Weight (kg) | 160 | 190 |

| Size (mm) | 688x585x1520 | 838x704x1670 |

| Air Flow (m³/h) | 1500 | 2000 |

| Noise (dB) | ≤65 | ≤70 |

| Power (kW) | 1.1 | 2.2 |

| Voltage | AC380V / 50Hz / 3-Phase | AC380V / 50Hz / 3-Phase |

| Negative Pressure (Pa) | 1800 | 2200 |

| Wind Speed (m/s) | 17 | 20 |

| Application |

Wave Soldering

During wave soldering, flux fumes and heated solder can release harmful gases and particulates. The XS1500-10 effectively captures and filters these emissions at the source, preventing operator exposure and maintaining air quality.

Reflow Soldering

In reflow soldering processes, the heat used to melt solder paste can generate volatile organic compounds (VOCs) and fine smoke. This fume extractor removes these contaminants to protect sensitive electronics and ensure a cleaner, safer environment.

Laser Welding

Laser welding produces dense fumes, metallic particles, and laser-generated airborne contaminants. The XS1500-10 captures these emissions before they spread, protecting both operators and optical equipment while improving overall workshop cleanliness.

Laser Cutting

Laser cutting of metals and plastics generates significant smoke and dust. This extractor prevents accumulation of fumes and particulates, reducing fire hazards, protecting machine optics, and enhancing cutting precision through improved visibility.

Electronics Manufacturing

In environments with high-precision electronics production, maintaining clean air is critical. The XS1500-10 helps eliminate airborne pollutants that could settle on circuit boards or damage sensitive components, ensuring higher product yield and reliability.

Metal Processing

Processes such as grinding, polishing, or welding metals produce fine particles and metal dust. The fume extractor minimizes worker exposure to hazardous materials, keeps equipment clean, and supports compliance with occupational health standards.

|

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR