Vision Seam Tracker

Features

|

·One-key start, easy to operate;

·Manual/automatic dual mode control;

·Welding process can be visualized remotely;

·The software can be reversed left and right;

|

|

·Fanless design of key components;

·The smoothness of tracking welding can be adjusted;

·Replaceable splash guard.

|

|

Princlples

It is composed of a lens, an optical sensor, and a central processing unit. It does not require an external industrial computer. It can be directly connected to the robot controller, PLC and other multi-axis controllers, and directly output the calculation results to realize real-time tracking, online detection,automatic deviation correction and abnormal alarm, etc. Features.

Solve problems

·One-click solution to the detection range, capability and common problems in the welding process;

·Real-time correction of seam deviation,precise guidance of welding torch for automatic welding;

·Effectively solve the problems caused by welding seam deviation;

·It can solve the problem of two-dimensional tracking welding of small welds.

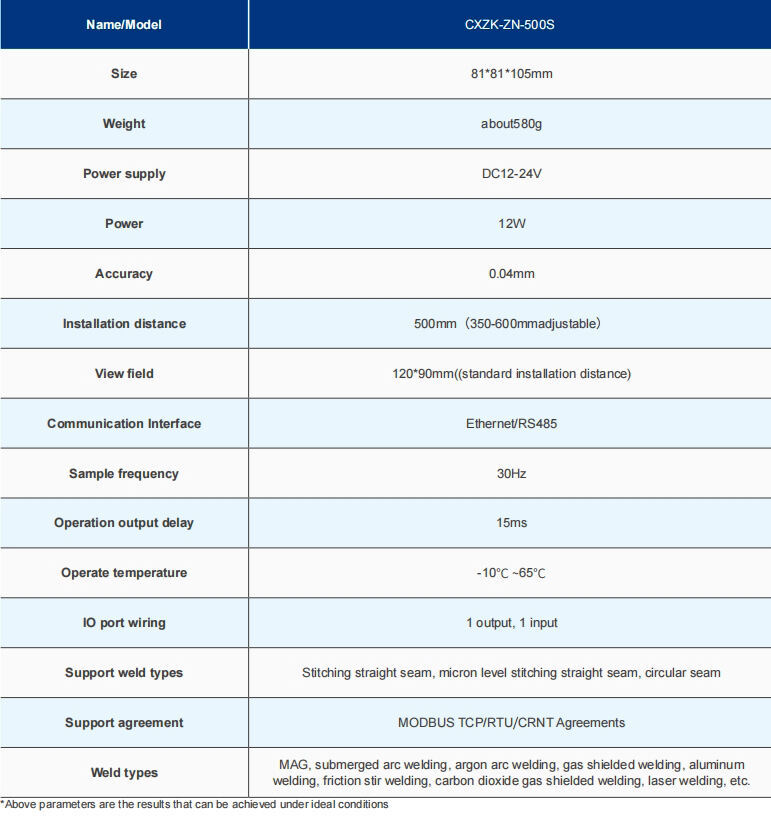

Product Parameters

Scope of Application

·Supports standard serial and network communication protocols;

·Communication with welding machine, PLC or industrial computer through IO port to realize automatic control;

·Suitable for all kinds of welding machines such as straight seam welder, circular seam welder, welding trolley, gantry, cross welding machine;

·It can communicate with robots of various brands to solve workpiece clamping deviation.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR