Upgraded Mold Laser Welding Machine

Product Description

| achine is selected by the Fortune Global 500 for laser welding of precision plastic molds, laser welding of mirror plastic molds, and laser welding of precision die-casting molds. It has made great contributions to the domestic mold repair industry. |  |

|

High efficiency, high performance, high precision Because the size of the focused laser is small, the heat-affected area is small, and the processing is fine, it can complete some processes that cannot be achieved by conventional methods. |

Product Advantages

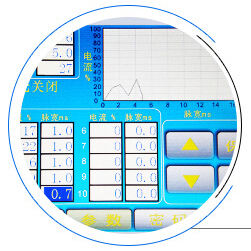

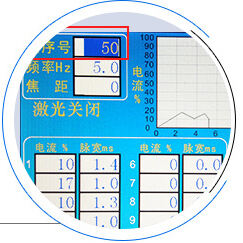

Chinese or English interface can be selected, suitable for use by people from different countries. The laser power value is provided for the operator's reference to select appropriate parameters.

|

01 Different laser pulse waveform settings For steel, aluminum, copper, etc., laser processing with different waveforms can be used to improve the controllability of the penetration of laser welding and the impact of cooling time on the hardness of the material. Archive the preset waveforms so that even beginners can operate it easily. |

|

02 Up to 50 sets of waveform parameter storage Since different materials will be welded at any time during mold laser welding, the system parameters can be retrieved and used at any time without re-editing the waveform, which is convenient and fast. |

|

|

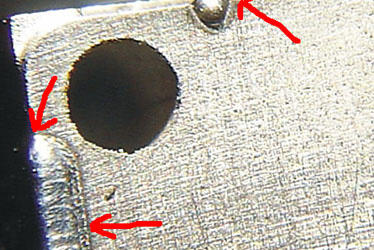

03 Independent patented anti-glare LCD shutter The time setting of the LCD eye protection is provided. Different light blocking times can be set for different pulse widths to protect the operator's eyes from the discomfort of laser glare. |

|

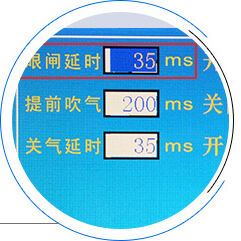

04 Argon gas delay shut-off time can be set The argon gas delay shutdown time after the laser is turned off can be set. This function effectively protects the welding position during high-power welding. It is always protected by argon gas during the cooling process, always maintaining the original color of the metal, and greatly improving the welding quality of high-power laser welding. |

|

Application

This mold laser welding machine has been improved. It uses the second-generation precision single-lamp power supply independently developed by Tongfa as the lamp pump driving power supply. It is equipped with a touch screen and is more convenient to operate. The host machine is equipped with a manual lift of the laser head and an electric lift of the workbench button to realize laser welding processing of molds with different thicknesses. This model is more suitable for laser repair welding of various types of high-precision injection molds, laser repair of precision plastic mold parts, and laser burning of beryllium copper parts of plastic molds; it can laser repair the wear and tear that occurs during the use of molds; and perform laser repair on machinery. Machining errors, EDM errors, mold glue reduction design changes, etc. require mold modifications, which play a key role in making up for the huge losses caused by processing errors.

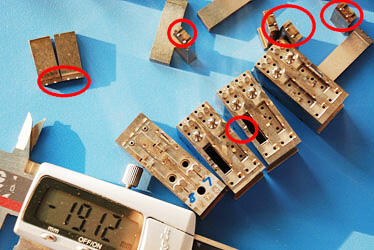

Sample display

|

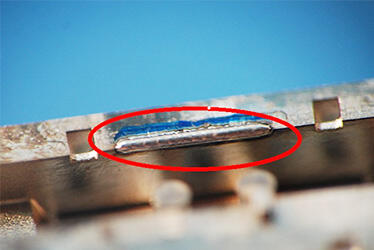

Laser welding of injection mold parts |

Laser welding of mold insert ejection pin holes and corners |

|

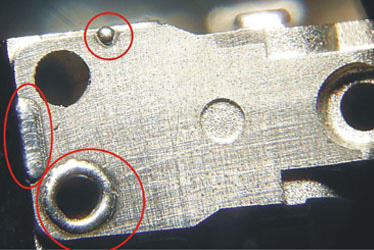

Laser welding of sharp corners of mold precision inserts |

Laser welding of precision mold inserts |

|

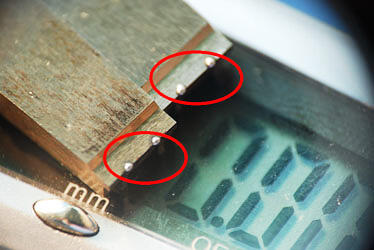

Laser welding corners of precision parts without damage or undercut |

The laser head can be turned and the microscope can be turned |

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR