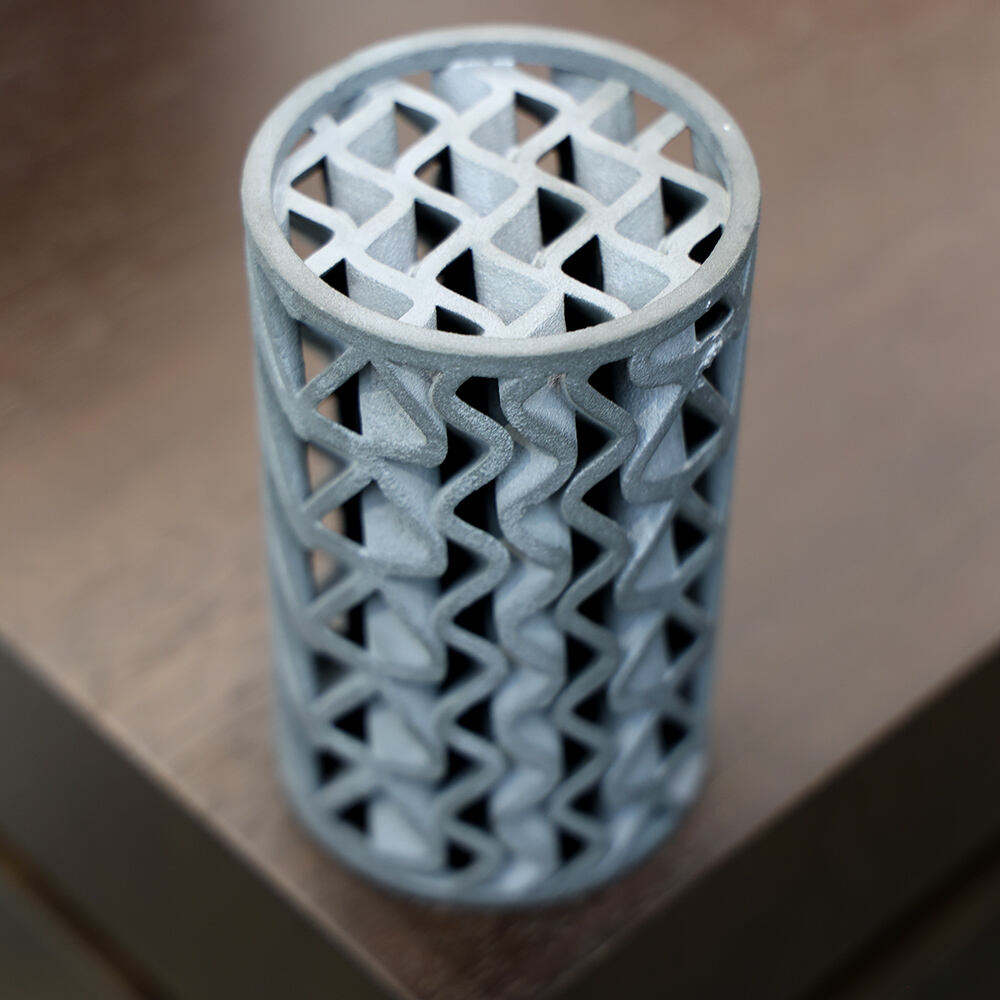

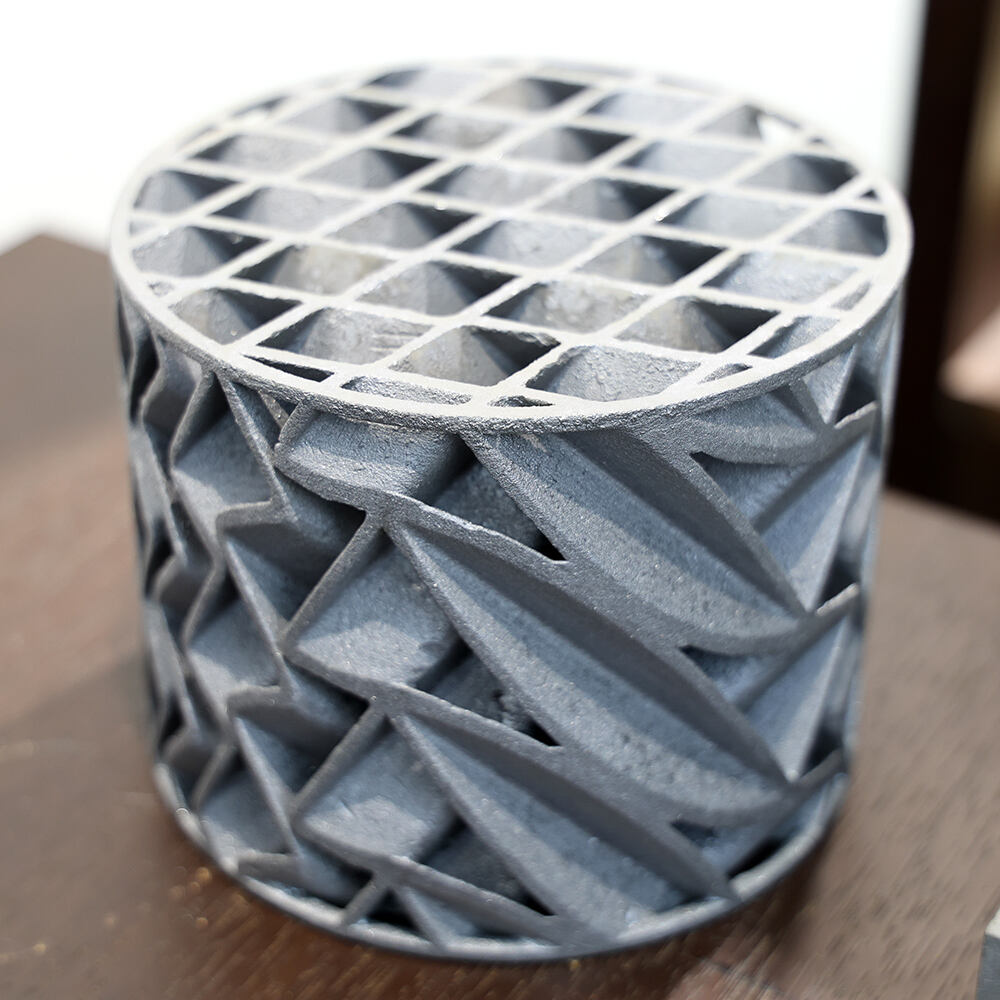

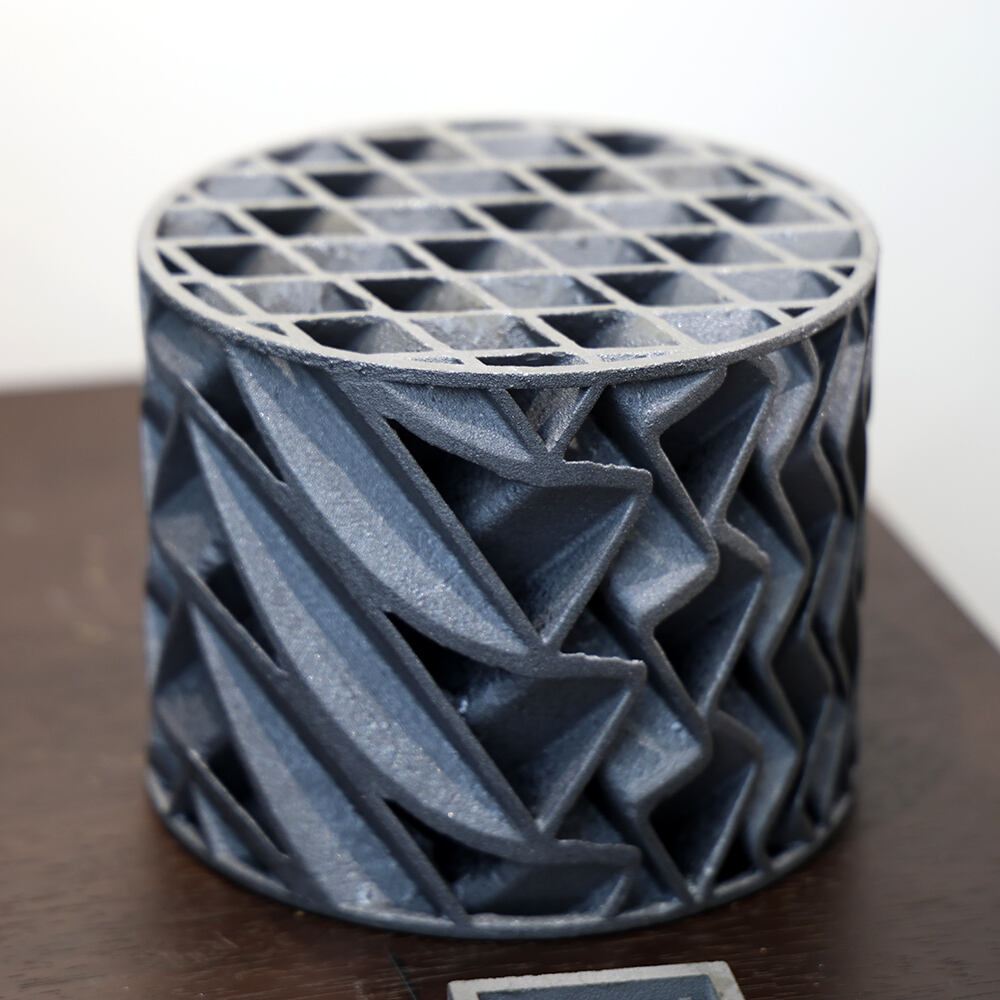

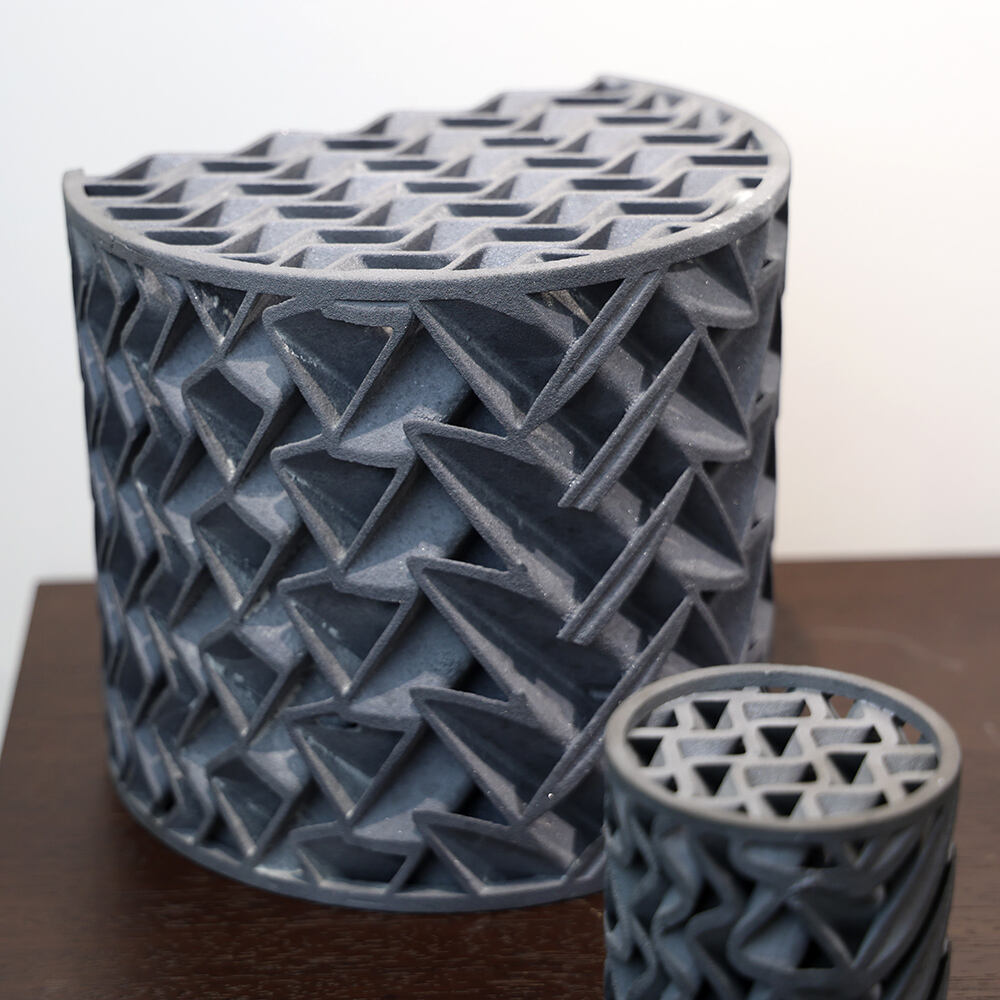

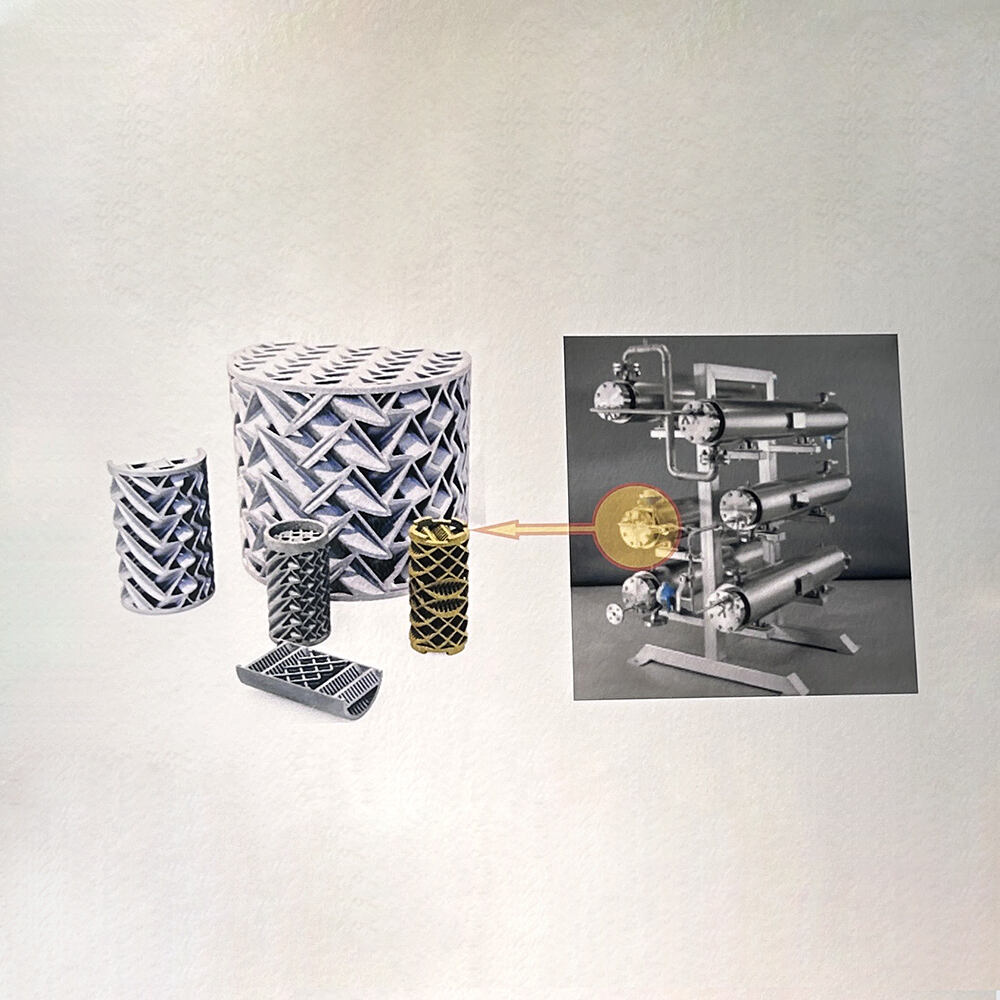

SiC Ceramic Parts for Chemical and Pharmaceutical Use

| Product Description |

Our 3D-printed Silicon Carbide (SiC) ceramic static mixers are designed for use in pharmaceutical and chemical industries, offering exceptional performance in fluid mixing and temperature control. These components are engineered to induce left or right rotational flow, enhancing turbulence and improving mixing efficiency within pipelines. The optimized geometric structure ensures uniform temperature distribution and minimizes flow resistance.

| Key Features |

| Advanced Design: Unique 3D lattice structure promotes efficient fluid mixing and heat transfer. |  |

|

High Performance Material: Made from SiC ceramic with excellent mechanical strength, corrosion resistance, and thermal stability. |

| Superior Mixing Efficiency: Enhances chemical reactions and heat exchange through consistent turbulence. |  |

|

Cost & Energy Savings: Reduces preparation time by over 70%, lowers production costs by up to 60%, and minimizes residual mixing to less than 1%. |

| Reliable Quality: Ideal for aggressive media environments such as acid, alkali, salt, and other corrosive fluids. |  |

|

Scalable for Industrial Use: Verified by domestic listed companies and now in full-scale production. |

| Applications |

Chemical processing

Pharmaceutical manufacturing

Semiconductor equipment

Industrial fluid systems

We specialize in the production of customized SiC ceramic mixing elements using advanced 3D printing technology. If you require tailored sizes or structures, feel free to contact us for inquiries and collaboration.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR