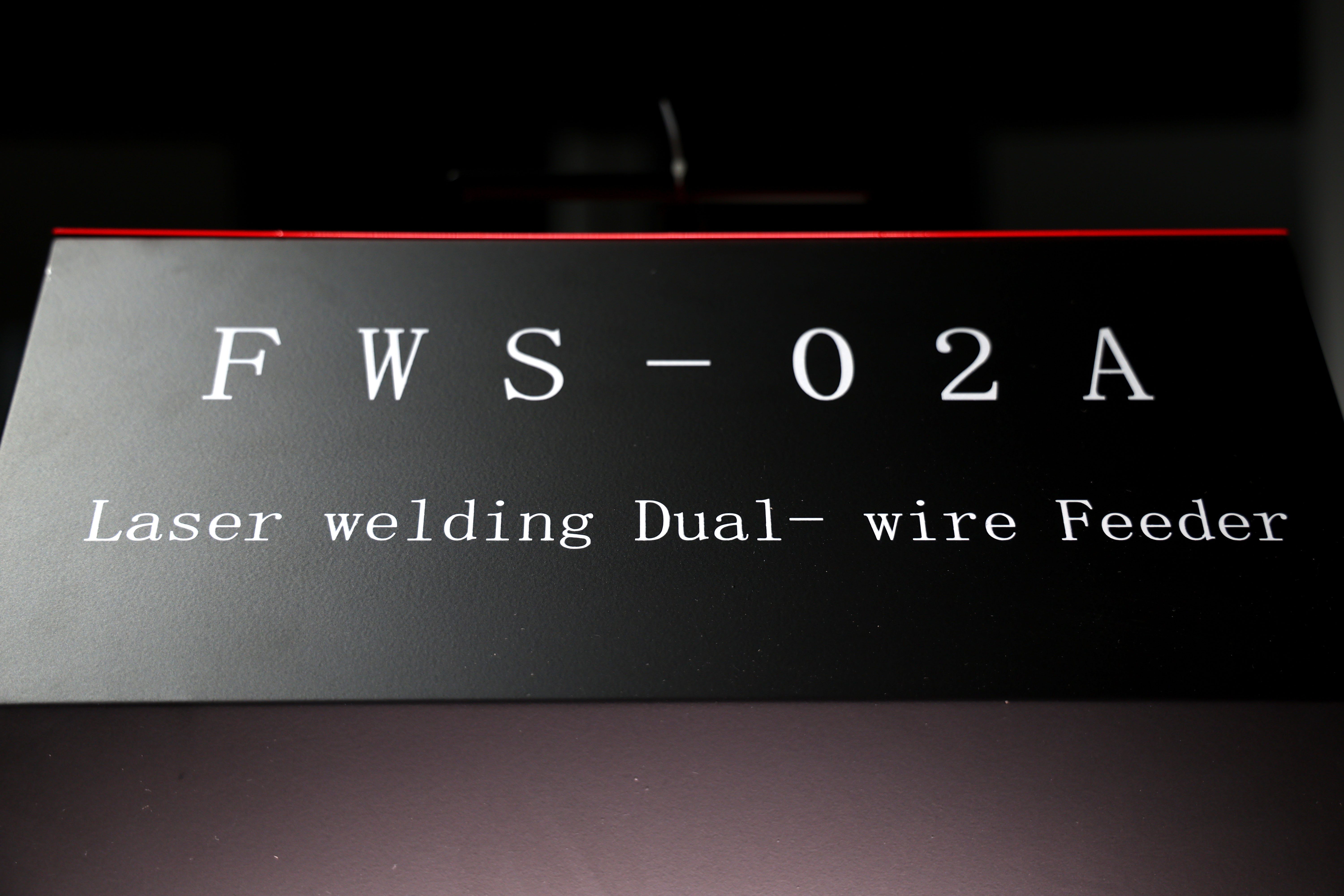

Relfar Double Wire Feeder for Laser Welding

Relfar Wire Feeder for Laser Welding | High-Efficiency Dual-Drive System

Product Description

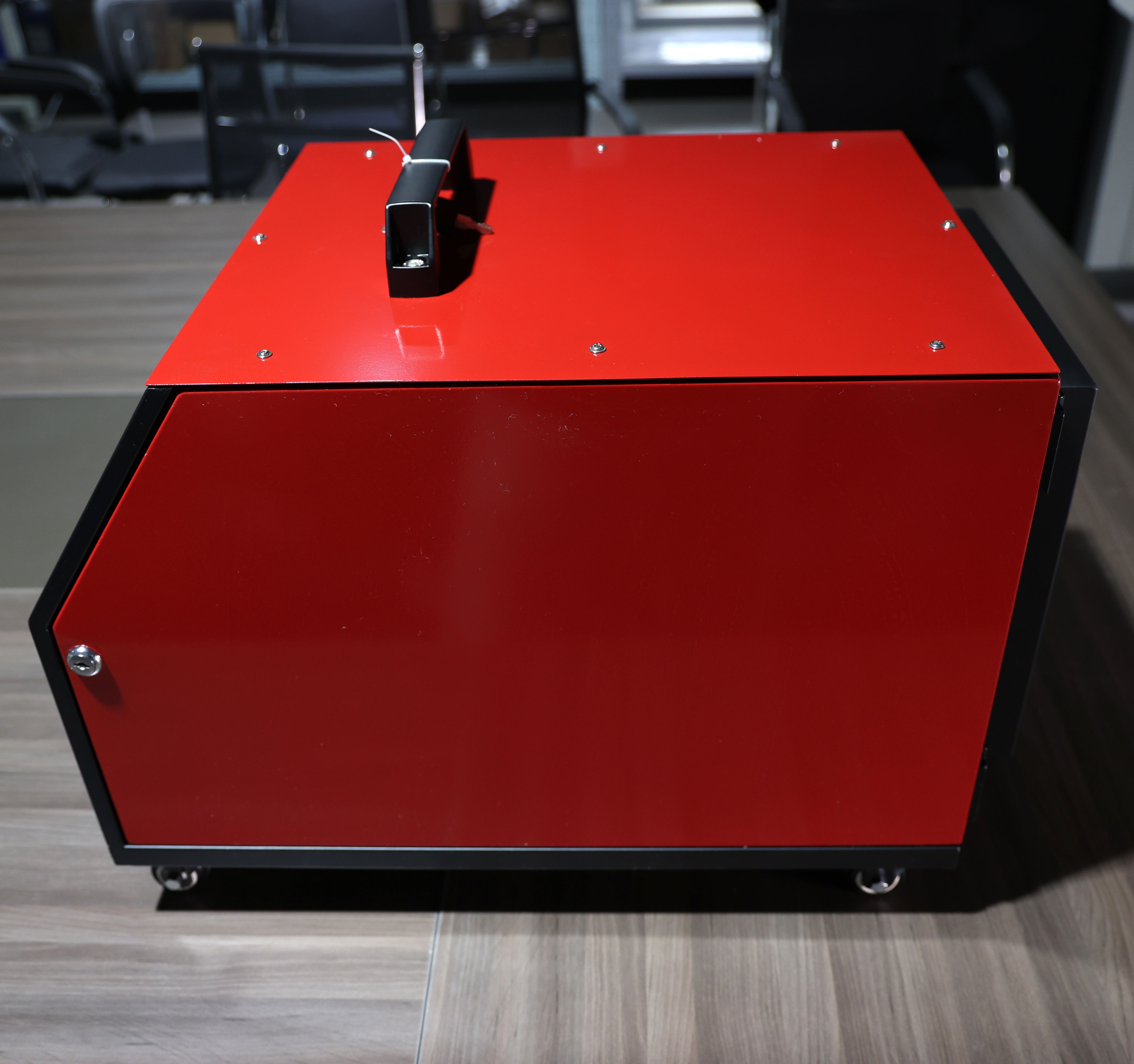

The Relfar Wire Feeder is designed for precision and efficiency in laser welding applications, making it the ideal choice for industries such as sheet metal, hardware, and new energy welding. Featuring advanced dual-drive technology, a powerful motor, and user-friendly mobility, this wire feeder enhances productivity and ensures stable wire feeding for seamless welding results.

Key Features

-

High-Power Motor

Ensures fast and precise wire feeding, significantly improving welding efficiency. -

Dual-Drive System

Offers robust thrust and exceptional stability during wire feeding operations. -

Brake-Resistant Spool Shaft

Equipped with a brake system to prevent wire slack when the motor stops, ensuring smooth operation. -

Large Wire Storage Capacity

Supports extended welding sessions without frequent refills, boosting overall productivity. -

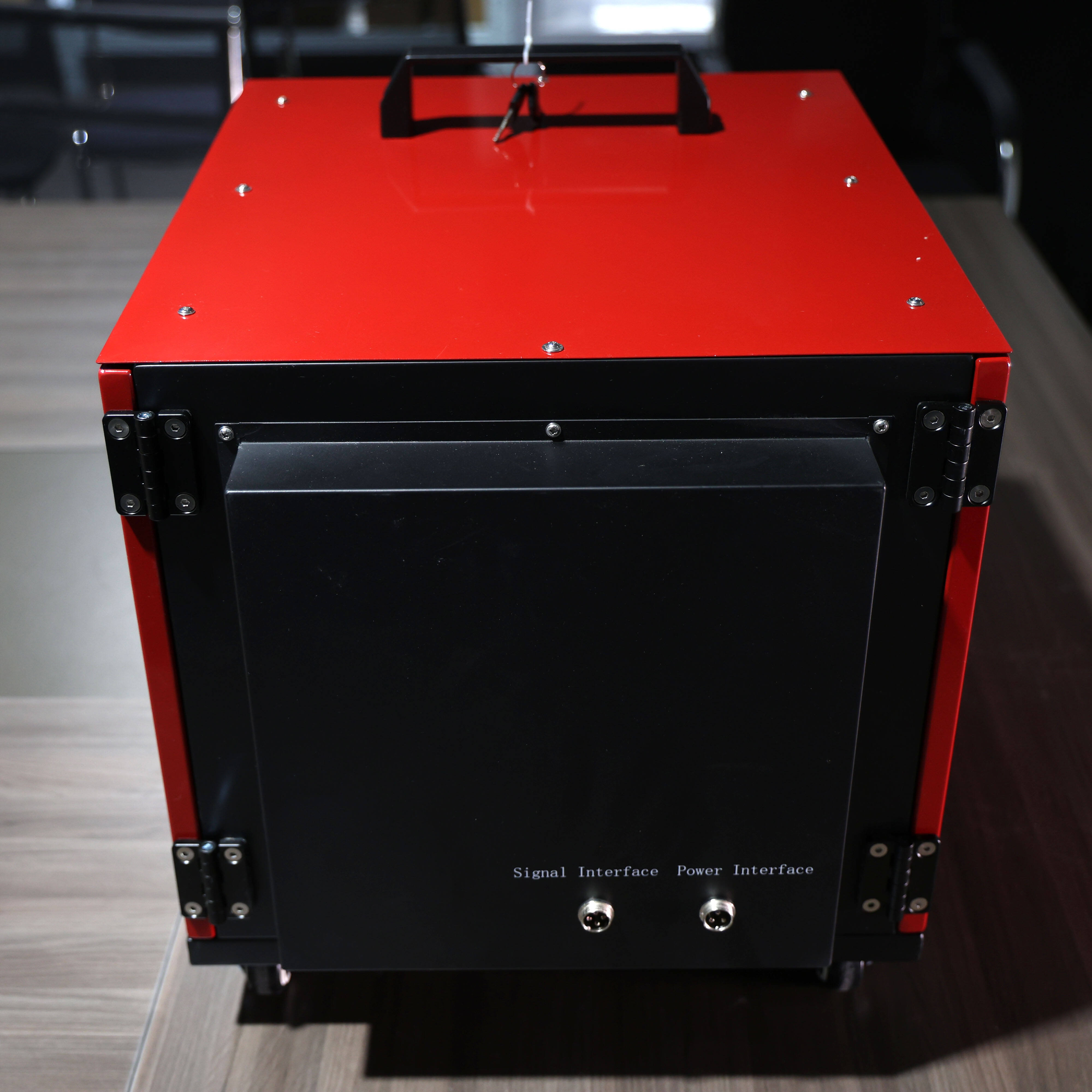

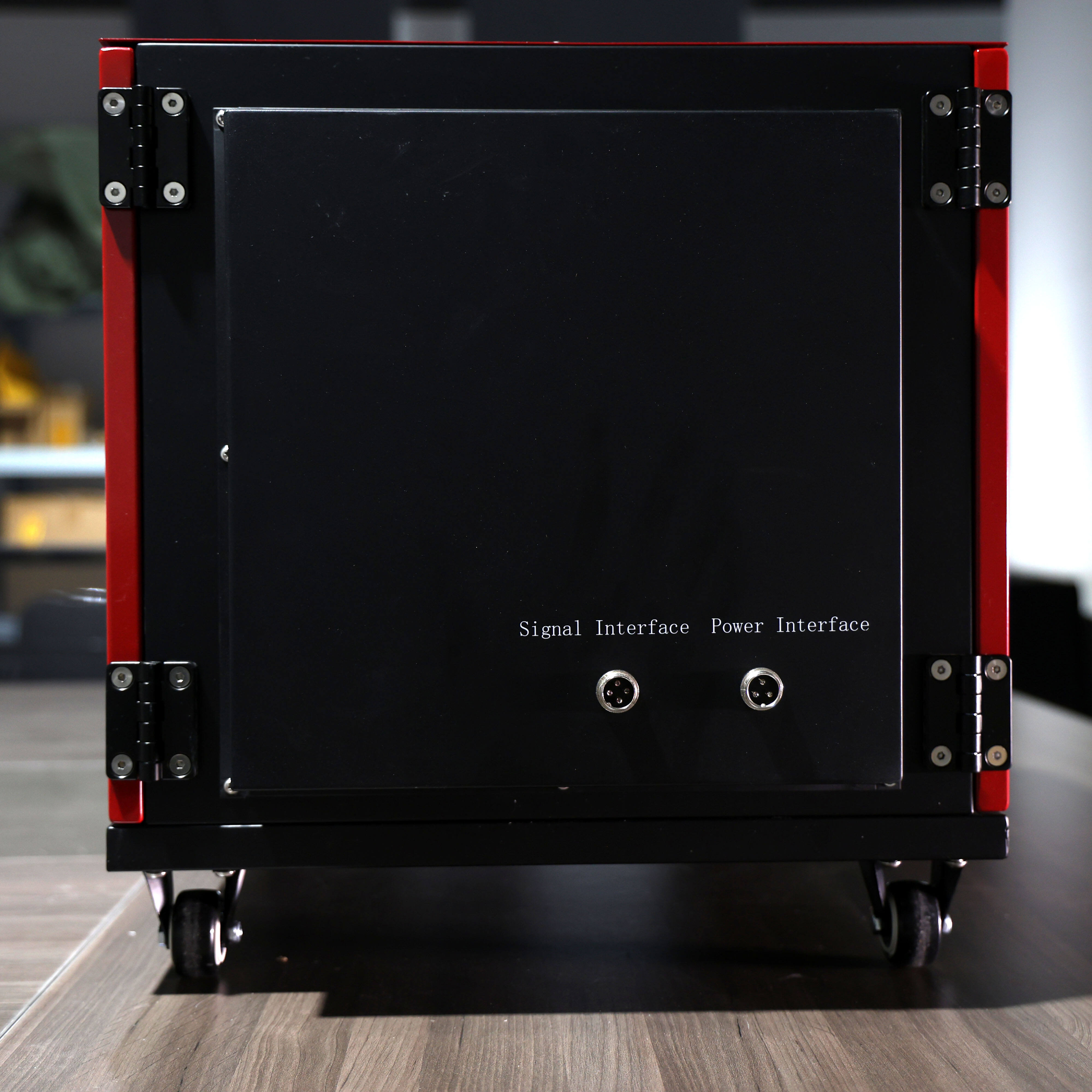

Integrated Sliding Wheels

Built-in wheels allow easy mobility and repositioning, enhancing operational flexibility.

|

|

Specifications

- Motor Type: High-power motor with dual-drive system

- Capacity: Large wire storage

- Mobility: Sliding wheels for portability

- Safety Features: Brake-resistant spool shaft to prevent wire slack

|

|

| Welding wire weight | 25KG maximum |

| Wire core diameter | 3.0m maximum |

| Maximum wire feeding speed | 80mm/s |

| Motor type | 57 stepper motor |

| Reduction ratio | 1:05 |

| Gross weight | 16.2KG |

| Power supply | 220V |

| Overall dimensions | 560mm long * 240mm wide * 472mm high |

|

|

|

|

Applications

- Sheet Metal Industry: Perfect for precision welding of thin and thick metal sheets.

- Hardware Industry: Ensures stable and high-quality welds for metal components.

- New Energy Welding: Supports modern welding processes for battery cases, EV parts, and more.

|

|

Why Choose the Relfar Wire Feeder?

With its powerful motor, advanced dual-drive system, and innovative features like brake-resistant spool shafts and large storage capacity, the Relfar Wire Feeder is engineered to meet the demanding requirements of industrial welding tasks.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR