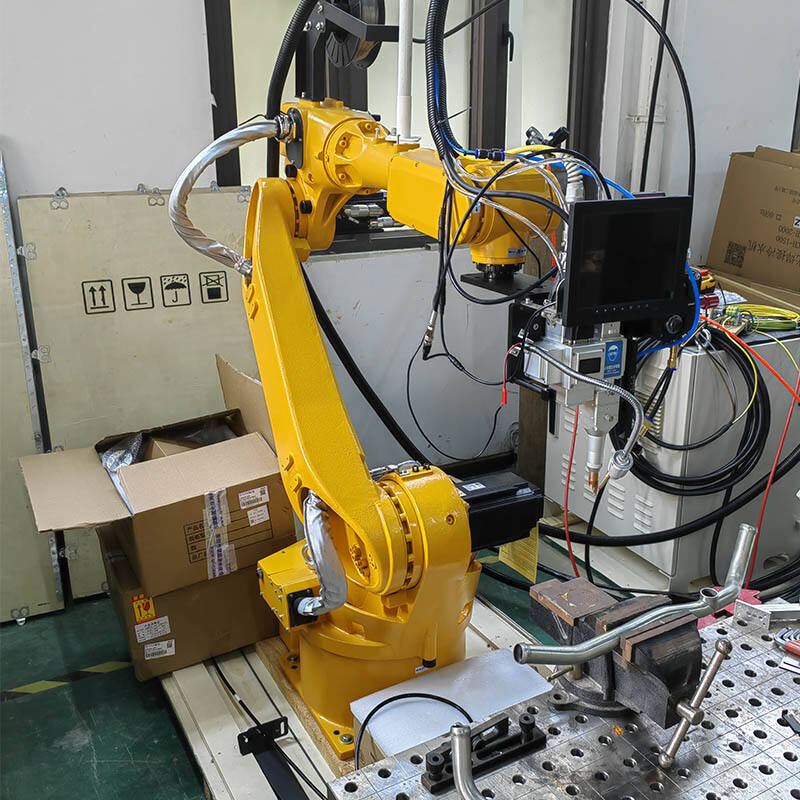

Robot Laser Welding Machine

Product Description

The robot laser welding machine is a specialized automatic welding machine designed for laser welding of three-dimensional workpieces. It combines light, machinery, and electricity, and consists of three major systems: industrial robots connected by shafts. It is used in conjunction with different-sized auxiliary fixtures on a welding workbench to achieve laser automatic welding of various metal materials like carbon steel, stainless steel, and aluminum alloy.

Specifications

| serial number | components | Brand and model | Remark |

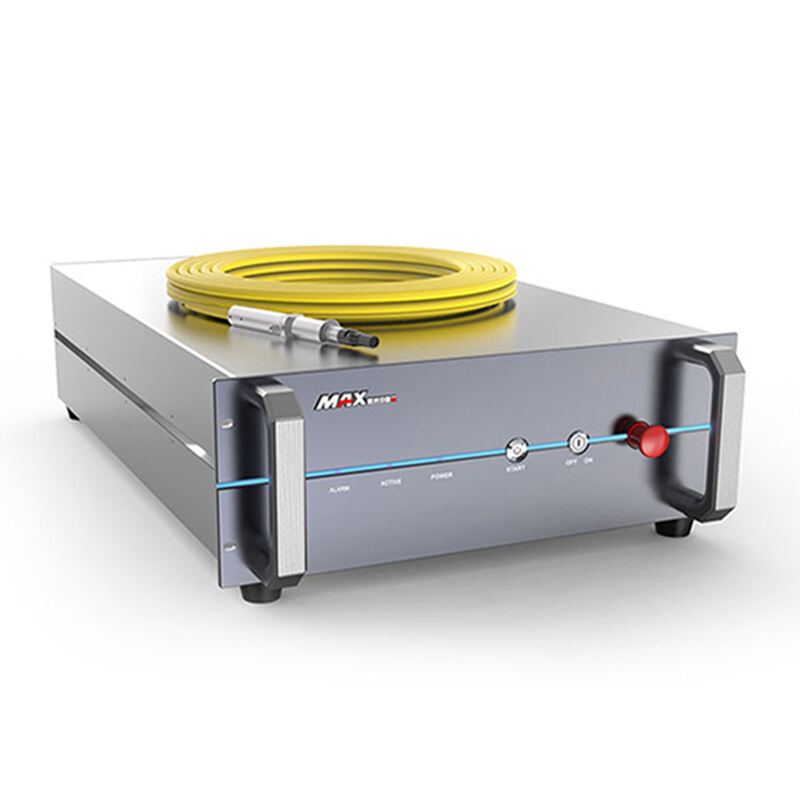

| 1) | Fiber LaserSource | MAX | 1set |

| 2) | 6-axislinkage industrial robot | ESTUN ER12-1510/ER20-1780 | 1 set(including robotic arm, control cabinet, teaching pendant) |

| 3) | Fiber laser special welding head | BWT30+PC | 1set |

| 4) | Fiber laser cooling system | Hanli | 1set |

| 5) | Cabinet | DMK | 1set |

| 6) | Stabilizer | Shanghai Xishun/Dongguan Jinbao | Optional |

| 7) | Welding fume purification device | Fume filter X500/X700 | Optional |

| 8) | Provide random special tools and spare parts (including laser protective glasses) | 1set | |

| 9) | Provide equipment related technical information | 1set |

1) Fiber Laser Technical Parameters

The robot laser welding machine utilizes a 3000W fiber laser, which offers high photoelectric conversion efficiency and a good beam mode. It incorporates fiber transmission, enabling long-distance processing while being compatible with robot integration. Additionally, its compact size makes it easy to transport. The laser power can be modularized, allowing for gradual increases based on specific requirements. The machine also features a multi-optical output shutter, providing versatility for various applications.

| How the laser works | Continuous / Modulation |

| wavelength | 1075nm±5 |

| Rated output power | 2000W |

| beam quality BBP | ≥2.0 |

| Modulating frequency | 5KHz |

| Output power stability | 0.02 |

| Output fiber core diameter | 50µm |

| Rated input voltage | 400±10%VAC |

| power dissipation | <10kW |

| working environment | 0-45ºC |

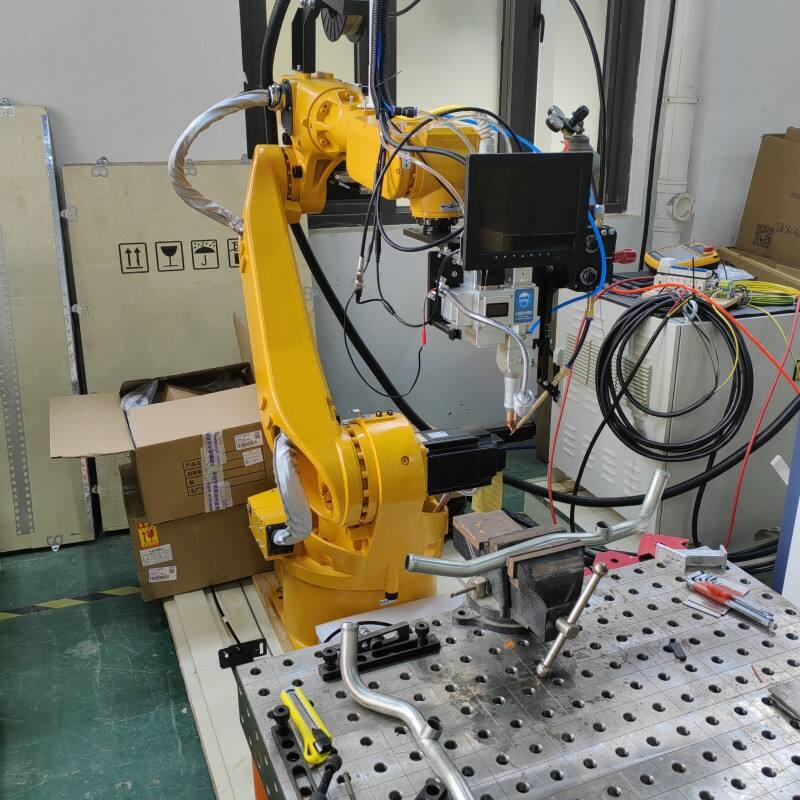

2) Technical characteristics and indicators of six-axis industrial robots

1.High reliability and durability, with long uptime and extended maintenance intervals.

2.The robot exhibits fast movement and short operation cycle times. Yaskawa's motion control technology optimizes acceleration and deceleration, minimizing the robot's working cycle time.

3.It delivers high precision, ensuring stable production quality with excellent trajectory accuracy and repeatability positioning accuracy (RP=0.03mm).

4.The robot possesses significant power and versatility, with payload options ranging from 12kg to 20kg and a maximum reach distance of 1.780m.

5.It is designed to withstand harsh production environments, featuring a sturdy and durable construction. It has an IP67 protection level and can be steam cleaned. It is available in clean room type (class 100) and "casting expert type."

6.The machine offers good versatility, allowing for flexible integration and production. All models can be installed upside down for added convenience.

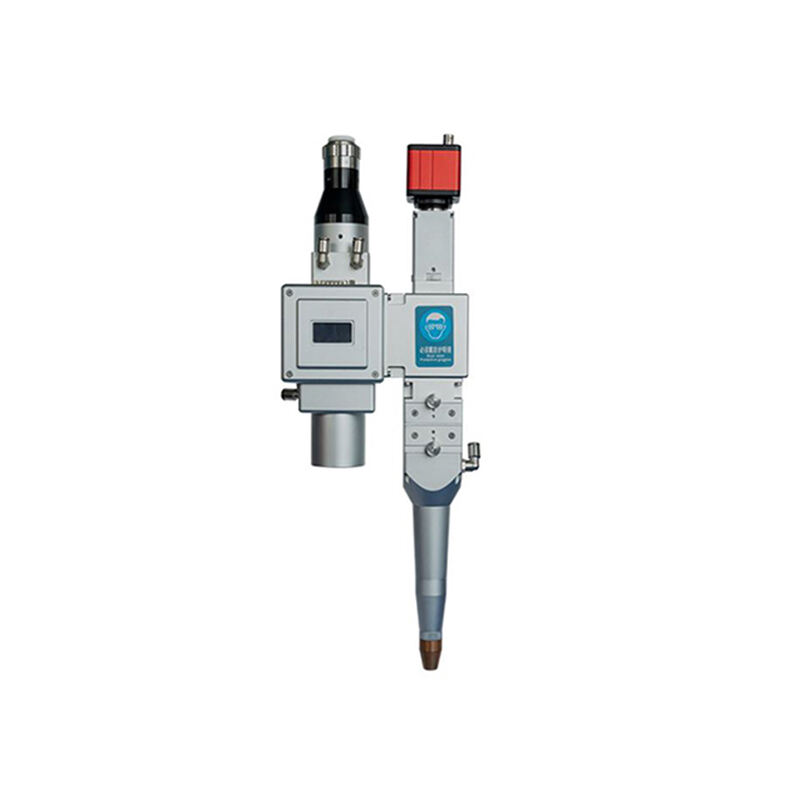

3) Qilin BWT30 swing welding head+PC

7 swing patterns for different process requirements

Display control, compatible with offline, PC control and other working modes

Double protection window design, dust-proof and slag-proof design, efficient water cooling, stable and reliable

Provides cameras, industrial lenses, monitors and blue light sources

Optical solutions optimized for surveillance

Make the welding process clearly visible

Integrated drive and control, strong anti-interference ability, simple external wiring

Technical parameters of Qilin BWT30 swing welding head

| power level | 2000W |

| Clear Aperture | 26mm |

| X Axis Oscillation Amplitude | 0-5mm |

| YAxis Oscillation Amplitude | 0-5mm |

| wobble frequency | 2-30Hz |

| Weight | ~2.1kg |

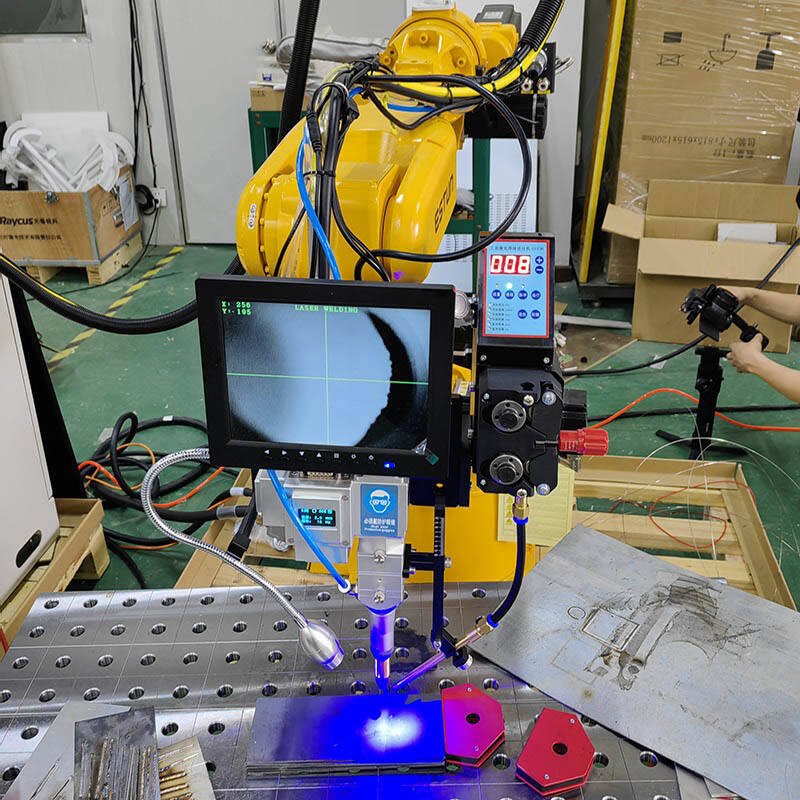

4) CCD Monitoring System

With high-definition CCD camera and high-definition display

The magnification of the monitoring system is ≥20 times (the specific configuration is subject to the configuration of the exit head)

The welding process can clearly show the image of the welding seam position

With automatic red light indicating focusing function, the coaxial red light can accurately locate the welding part and correspond to the cross cursor on the display

The focus of the laser spot needs to be consistent with the focus of the CCD monitoring system (that is, when the welding part is clearly seen through the monitoring system, the focus of the laser spot is at the welding part)

During welding, the CCD can monitor coaxially, and determine the best welding spot or welding track at the welding position under the coaxial red light indication.

-

Robot laser welding machine

-

Robot laser welding machine

-

Robot laser welding machine

Quick Detail

1.Laser plane butt joint and lap welding: This includes welding of steel plates with plane butt seams and plane lap seams.

2.Laser surface butt and lap welding: This involves welding on the surface of materials, enabling butt and lap welding.

3.Laser combination welding of various special-shaped workpieces: The machine can weld different-shaped workpieces together using laser technology.

Applications

1.Automotive Industry: Used for welding car body parts, frames, exhaust systems, and other automotive components.

2.Manufacturing Industry: Employed in the welding of metal structures, machinery, and equipment.

3.Aerospace Industry: Utilized for welding aircraft components such as engine parts, landing gear, and structural elements.

4.Energy Sector: Used in the welding of power generation equipment, pipelines, and oil and gas industry components.

Competitive Advantage

1.Flexibility: They can handle a wide range of workpieces, including complex and three-dimensional structures, providing versatility in welding applications.

2.Precision and Quality: Manipulator laser welding ensures high precision and controlled heat input, resulting in clean and precise welds with minimal distortion.

3.Efficiency and Productivity: These machines can operate at high speeds, significantly reducing welding cycle times and improving overall productivity.

4.Automation and Integration: Manipulator laser welding machines can be integrated with robotic systems, enabling fully automated welding processes, reducing manual labor, and increasing efficiency.

5.Consistency and Reproducibility: Laser welding offers consistent and reproducible weld quality, minimizing defects and ensuring high-quality welds consistently.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR