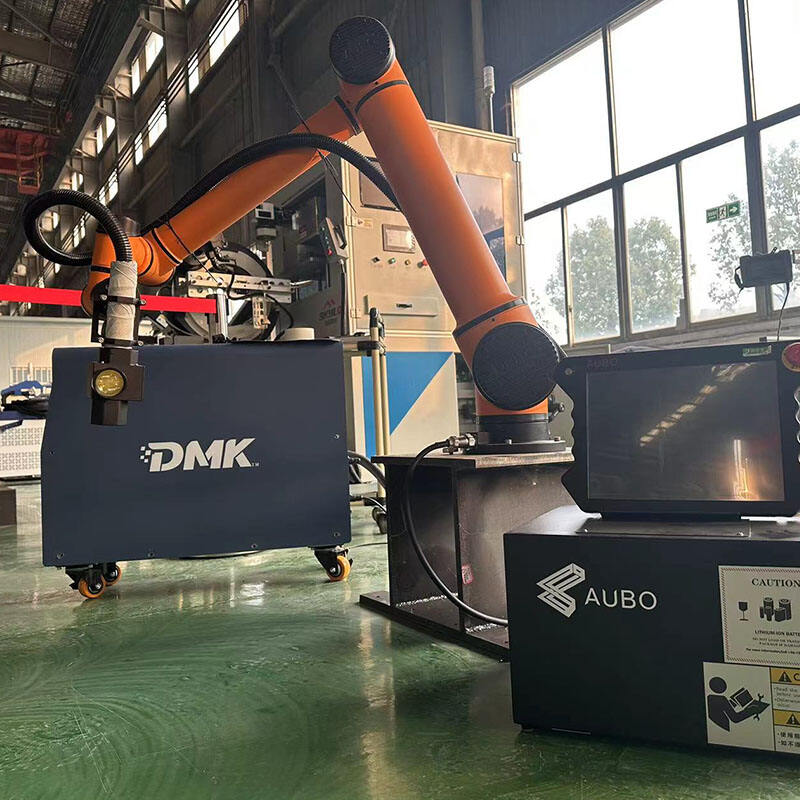

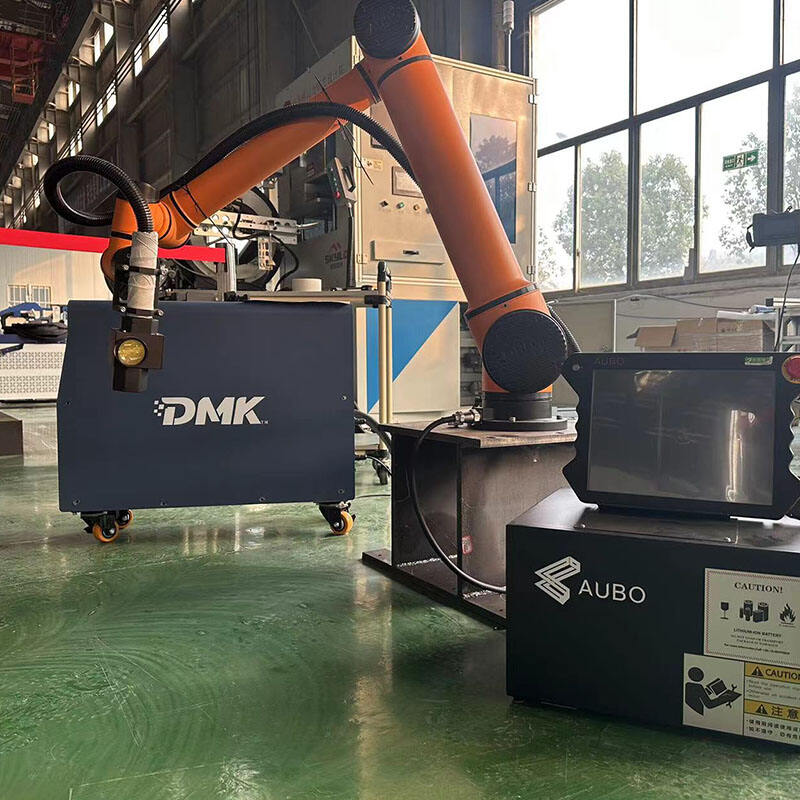

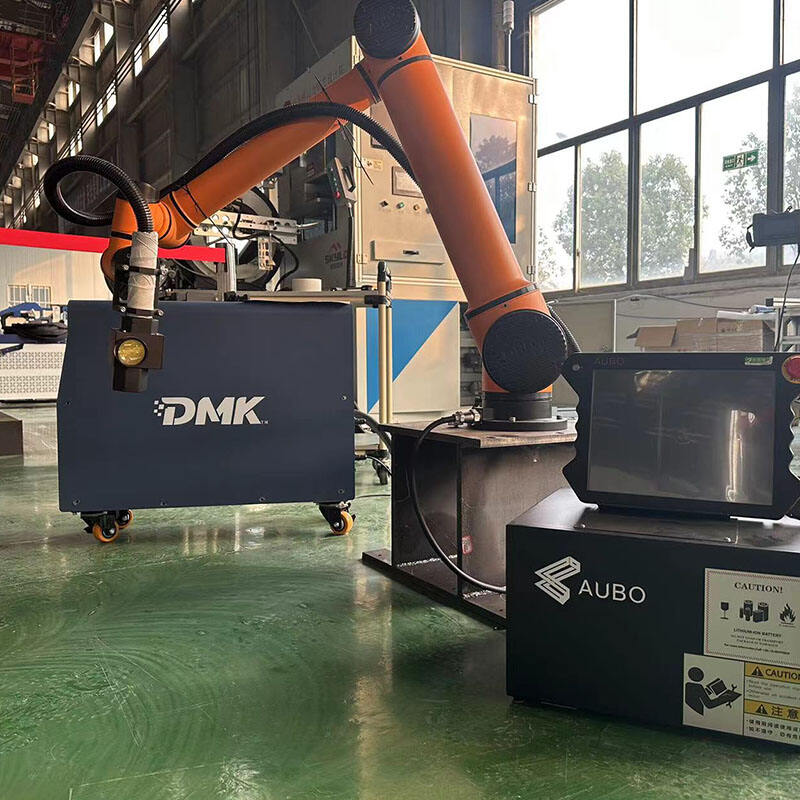

Collaborative Robot Laser Cleaning Machine

Product Description

Online collaborative cleaning integrates laser cleaning systems with collaborative robots, crawler robots, AGVs and other equipment, and enables precise and efficient cleaning by adjusting and programming various laser cleaning parameters through software. (Optional single-axis laser head / dual-axis laser head)

-Manipulator integrated automation

-Line integration

-High precision control

-Easy plug-in laser head design

-Linear laser beam laser maximum scanning line width 200mm

-Maximum laser scanning speed 20m/s

Specifications

| Serial number | Name | Specification | Quantity | Remarks |

| 1 | Laser mainframe | 200W, standard 5m fiber optic cable, length can be customized, with touch operation screen | 1 | Determine the laser power according to the cleaning object, can communicate with the robot |

| 2 | Cleaning head | 200W (100~300W universal) | 1 | Standard air cooling, water cooling can be customized |

| 3 | Cleaning head quick release clamps | Non-standard customization | 1 | With quick release latch, easy to disassemble |

| 4 | Collaborative robots | The load is more than 5KG. | 1 | Including control cabinet, demonstrator, operating radius according to product specifications |

| 5 | Working Platform | Non-standard customization | 1 | Custom design according to product specifications, cleaning form, can include product fixture |

-

Collaborative robot laser cleaning

-

Collaborative robot laser cleaning

-

Collaborative robot laser cleaning

Applications

1. Metal or glass surface coating removal, fast paint removal

2. Fast rust removal, and various oxides

3. Removal of grease, resin, gum, dust, stains, and production residues

4. Metal surface roughening

5. paint removal, rust removal, oil removal before welding or bonding, post-welding oxide, residue treatment

6. mold cleaning, such as tire molds, electronic molds, food molds

7. Oil removal after production and processing of precision parts

8. Rapid cleanup for nuclear power component repair

9. Oxide treatment, paint removal, rust removal during the production or maintenance of aerospace weapons and ships

10. Small space metal surface cleaning

11. Heritage cleaning, rock cleaning, building exterior surface cleaning

Competitive Advantage

Fiber laser Laser cleaning machine produced by unique coupling and control technology; high cleaning efficiency, adapt to a variety of complex environments, to achieve a long period of continuous cleaning operations;

Lightweight handheld gun head design with high tolerance depth of focus for one-touch operation;

Exclusive design and development of the use of the square light spot and light spot lap technology;

Easy to operate, power on, can be handheld or with robot to achieve automated cleaning;

Very high cleaning efficiency and time saving; stable laser cleaning system, almost maintenance-free.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR