Automated Laser Welding System

Product Description

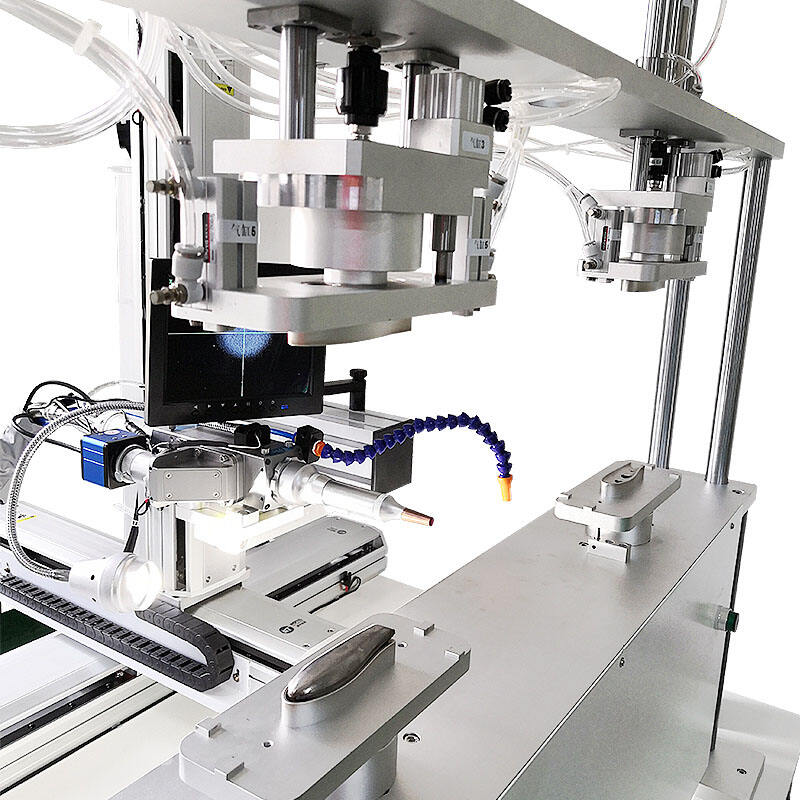

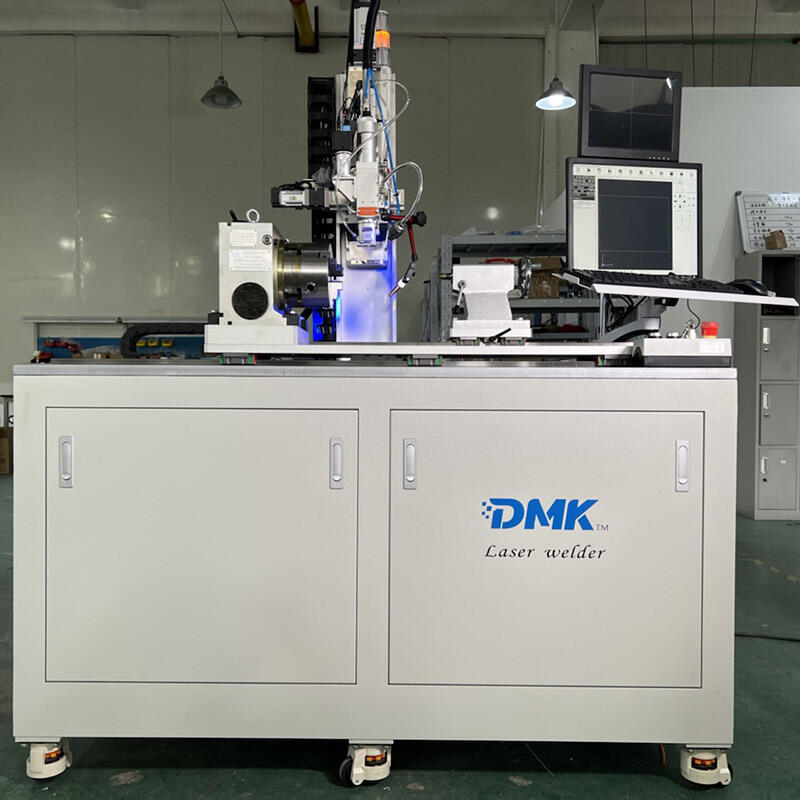

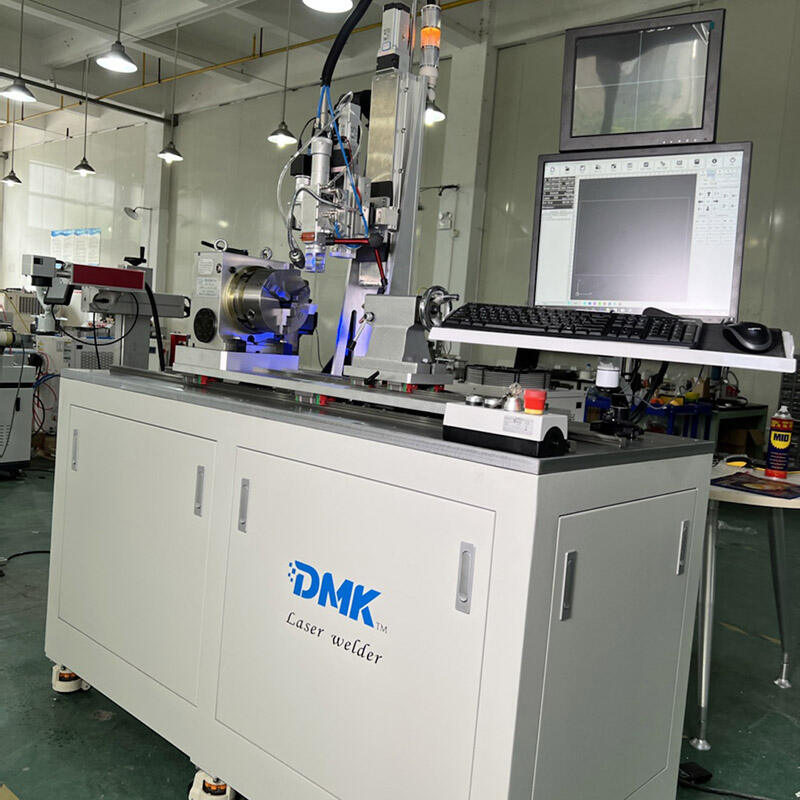

This equipment is designed to meet the above customer requirements and mainly consists of laser mainframe, water chiller, table and servo rotary table.

Workbench dimensions 1700 x 3000 x 2200 (specific to the design);

Laser host, water chiller, smoke purifier table layout can be changed according to actual needs.

Specifications

Laser host and its parameters:

| Laser Model | YLR-1000-K | ||||

| Optical properties | Characteristics | Lowest value | Typical values | Maximum value | Unit |

| Operation mode | Continuous/Modulated | ||||

| polarization state | Random | ||||

| Nominal output power | 1000 | W | |||

| Laser wavelength | 1070 | nm | |||

| Radiation bandwidth | 4 | 5 | nm | ||

| Switching light time | 30 | 50 | us | ||

| Output power instability | ±1 | ±3 | % | ||

| Red light indicates power | 0.1 | 1 | mw | ||

| Optical Output | Transmission fiber connectors | HLC-8,QBH Adaptation | |||

| Beam quality BPP, 50um transmission fiber | 1 | 1.1 | 1.5 | mm*mrad | |

| Beam quality BPP,100um transmission fiber | 2.3 | 3 | 3.7 | mm*mrad | |

| Beam quality BPP,200um transmission fiber | 6 | 8 | 10 | mm*mrad | |

| Length of transmission fiber | 10 | TBD | m | ||

| Transmission fiber bend radius (under force) | 200 | mm | |||

| Transmission fiber bend radius (unstressed) | 100 | mm | |||

| System Parameters | Working environment temperature | 10 | 50 | ℃ | |

| Humidity of working environment | 10 | 95 | % | ||

| Storage environment temperature | -40 | 75 | ℃ | ||

| Dimension | 448*677*177 | mm | |||

| Weight | 70 | KG | |||

| Cooling method | Water cooling | ||||

| Power supply parameters | Operating Voltage | 200-240V, 50/60Hz | |||

| Maximum power consumption | 2.7 | 3.2 | KW | ||

Structure and configuration of the workbench:

| Workbench model/name | Four-axis laser welding table | |

| Device Description | External dimensions (L*W*H) | 1100*600*2200mm |

| Performance Features | Workpiece XY axis movement, can weld point, straight line, circle, square or any plane figure composed of arc. | |

| Control method | PC control with 17" LCD monitor | |

| X-axis travel (electric) | 200mm,Repeatable positioning accuracy±0.03mm | |

| Y-axis travel (electric) | 150mm,Repeat positioning accuracy±0.03mm | |

| Z-axis travel (electric) | 300mm,Repeat positioning accuracy±0.03mm | |

| Drive method | Servo Drive | |

| Welding track input method | CNC programming or teaching method | |

| CCD weld seam monitoring | With 17-inch LCD monitor, easy to observe the processing quality and processing position | |

| Protective gas blowing method | Matching coaxial blowing | |

| Welding range | 200*150mm | |

| Maximum welding speed | 80mm/s (axis movement speed) | |

| Welding Software | UW Laser Welding Software | |

| Optional accessories | Pitch R-axis | |

| Safety grating | None | |

| Working power | Single-phase AC 220V, power 2KW | |

| Matching host model | IPG welding machine | |

UW-50P-150200C-FL-TF (with side shaft copper pipe blowing) parameters are shown in the following table.

| Collimator (Fc) | 150mm (specific to the design) |

| Focusing Mirror (Ff) | 200mm (specific to the design) |

| Laser power - wavelength | Maximum 500W |

| Cooling method | Water cooling |

| Weight | 3KG |

| Protective gas supply | Side-shaft |

| Operating ambient temperature | 5℃-55℃ |

| Storage environment temperature | 0℃-55℃ |

| Humidity range | 30-90%, avoid condensation |

List of delivery list:

| NO. | Project Name | Model | Quantity | Unit | Remarks |

| 1 | Laser welding machine | Non-standard | 1 | quantifier | |

| 2 | 3000W Laser | MAX | 1 | quantifier | IPG |

| 3 | Laser Chiller | Standard | 1 | quantifier | |

| 4 | Fiber optic | Standard | 1 | article | |

| 5 | Smoke Purifier | UWLZJCQ01 | 1 | quantifier | Optional |

| 5 | Spare parts | 1 | set | ||

| 6 | Instructions for use | 1 | set | ||

| 7 | Equipment Certificate of Conformity | 1 | portions | ||

| 8 | Delivery list (multiple) | 1 | portions | ||

| 9 | Random hanging signs | 1 | set | ||

| 10 | Equipment acceptance report | 1 | portions | ||

| 11 | Electrical schematic | 1 | portions | paper | |

| 12 | Air circuit schematic | 1 | portions | paper | |

| 13 | Site installation schematic | 1 | portions | paper | |

| 14 | Equipment Maintenance Manual | 1 | portions | ||

| 15 | List of wearing parts | 1 | portions |

Provide parts and special tools as detailed in the following table:

| NO. | Name | Quantity | Remarks |

| 1 | Protective lenses | 1 | 1 tablet each time |

| 2 | Focusing lenses | 1 | |

| 3 | Universal blowing mechanism | 1 | |

| 4 | Copper nozzle | 3 | One each for ø6/ø8/ø10 |

| 5 | Blue light spotlight | 1 | Switching power supply included |

Provide parts and special tools as detailed in the following table:

| No. | Name | Quantity | Unit | Remarks |

| 1 | Foot Switch | 1 | size | TFS-1 Iron |

| 2 | Protective glasses | 2 | vice | |

| 3 | Phillips screwdriver | 1 | put | φ6*250mm |

| 4 | Hexagonal wrench | 1 | set | TGK |

| 5 | Blowing balloons | 1 | size | |

| 6 | Product Certificate of Conformity | 1 | book | |

| 7 | Operation Manual | 2 | set | One set of paper and one set of electronic files |

| 8 | User acceptance report | 2 | portions | |

| 9 | Photo paper | 5 | page | |

| 10 | Mirror paper | 2 | this | |

| 11 | Chuck wrench | 1 | size | |

| 12 | General purpose screws | several | size | M4/M5/M6/M8 |

| 13 | Standard toolbox tools on the market | 1 | set |

-

Automated Laser Welding System

-

Automated Laser Welding System

-

Automated Laser Welding System

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR