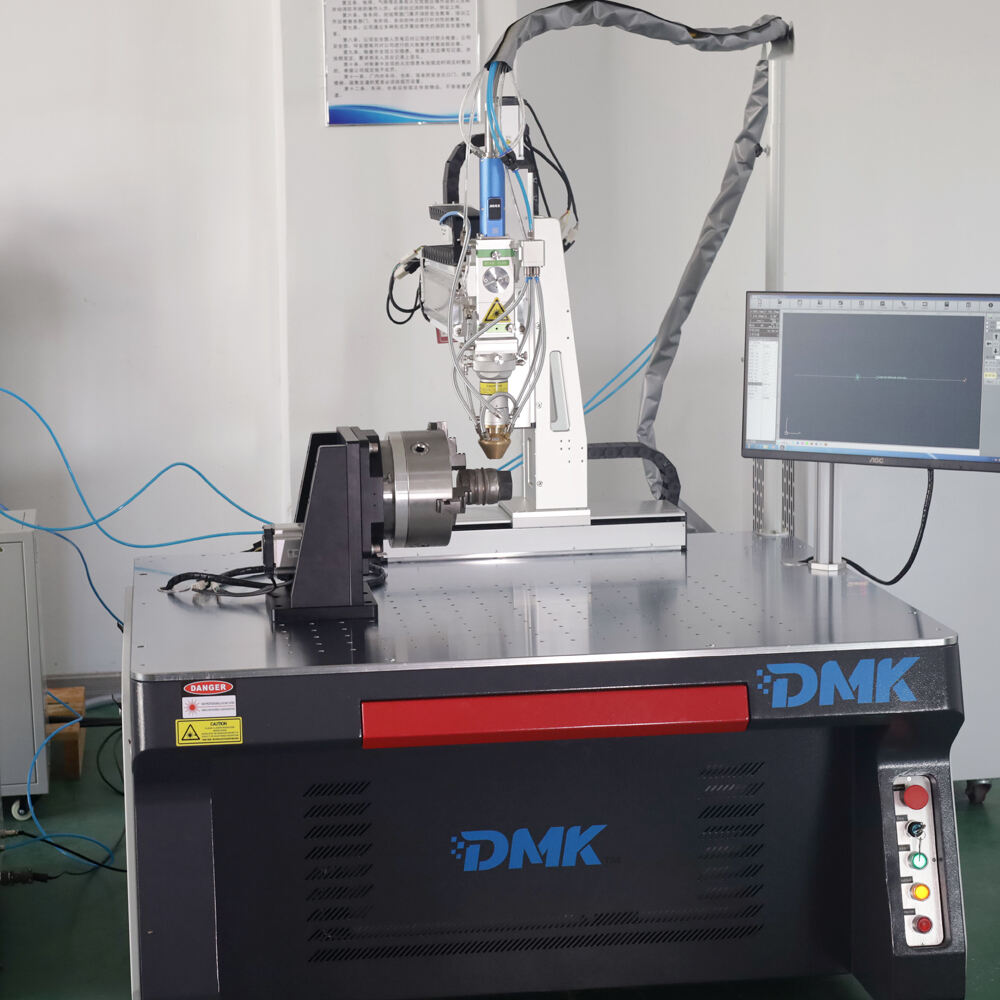

Multi-Functional Laser Cladding Machine

Product Description

Product Overview

This laser cladding machine is a highly integrated, multi-functional device widely used in surface repair, scientific research, mechanical manufacturing, hardware molds, oil and mining industries, and railway and aviation sectors. Utilizing advanced laser cladding technology, it efficiently enhances material surface properties such as wear resistance and corrosion resistance, while also supporting precise repairs of mechanical components.

Key Features and Applications

-

Material Cladding

- Nickel-based tungsten carbide cladding

- Copper alloy cladding

- Inner bore cladding

-

High-speed cladding for enhanced wear and corrosion resistance

-

Mechanical Parts Repair

- High-precision repair for damaged components, extending their service life

Technical Advantages

-

Easy Operation with No Specialized Skills Required

- Low operating costs and user-friendly software enable quick programming for complex workpieces.

- Low operating costs and user-friendly software enable quick programming for complex workpieces.

-

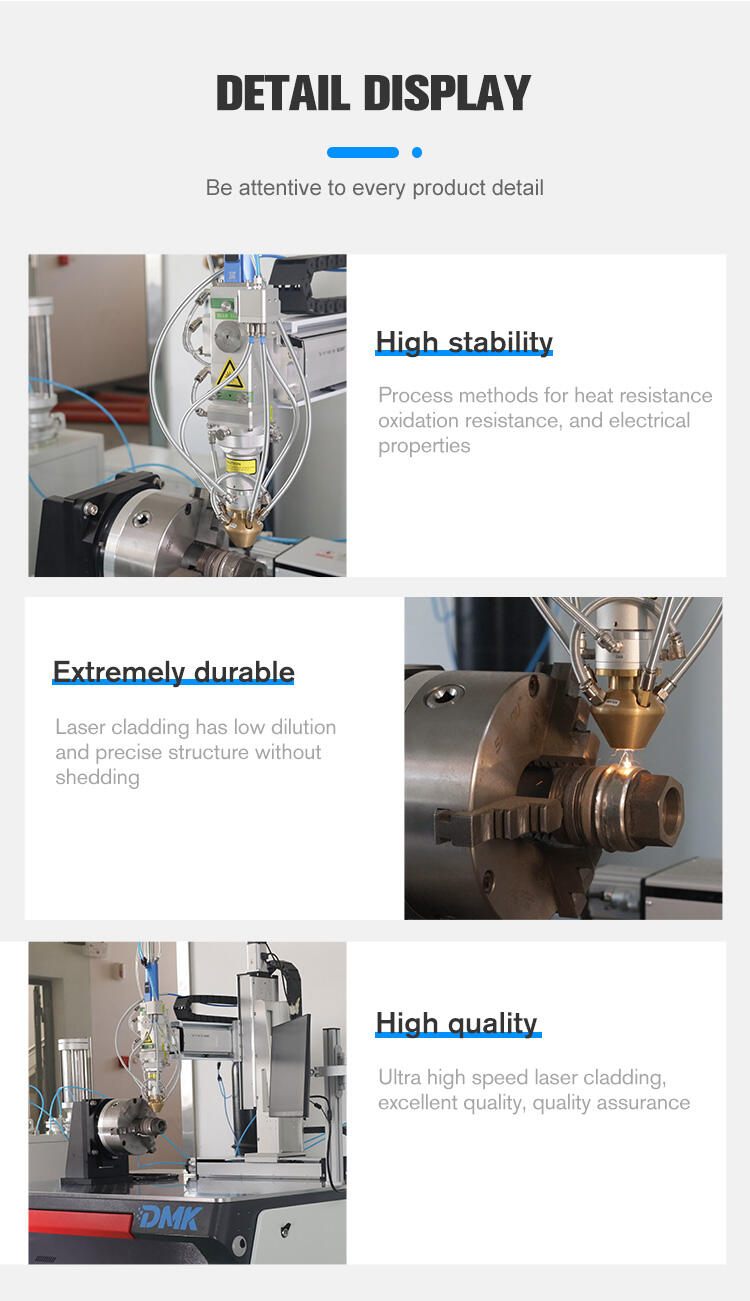

High-Quality Processing

- Supports surface and inner bore cladding with minimal deformation, preserving unaffected areas.

- Supports surface and inner bore cladding with minimal deformation, preserving unaffected areas.

-

Efficiency and Flexibility

- High-speed cladding capabilities (with compatible accessories) significantly improve productivity.

- High-speed cladding capabilities (with compatible accessories) significantly improve productivity.

-

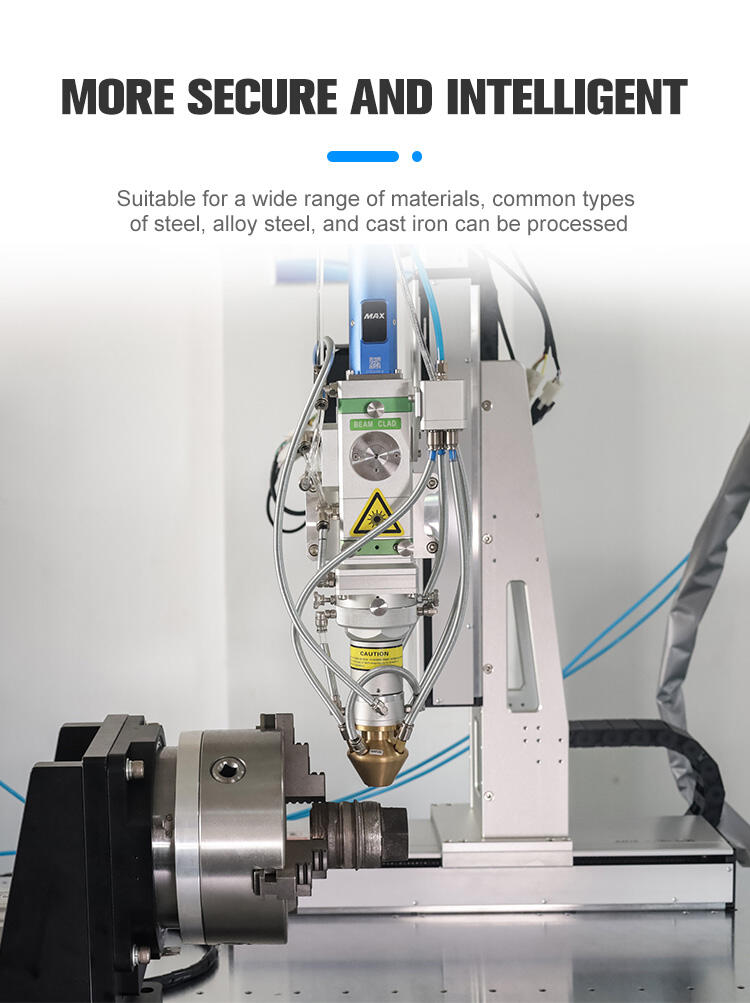

Wide Material Compatibility

- Suitable for various materials including steel, stainless steel, and cast iron.

- Suitable for various materials including steel, stainless steel, and cast iron.

-

Adaptability for Complex Workpieces

- Precisely clads any complex shapes on workpiece surfaces and inner bores.

System Configurations

-

Worktable

- Customizable Size: Non-standard dimensions tailored to specific applications.

-

Model Options:

- Standard desktop model

- Standard enclosed model

- Frame type

- Cast iron platform type

- Robotic model

- Multi-Functionality: Interchangeable heads for laser cladding, hardening, and welding (including inner bore and high-speed cladding). Protective enclosures available upon request.

-

Laser Source

- Customized continuous fiber laser with high electro-optical efficiency and anti-reflective features.

- Optimized beam quality ensures uniform energy distribution, higher powder utilization, and refined cladding surfaces.

- Supports power outputs of 900W or higher for cladding and hardening tasks.

-

Laser Cladding Head

- Suitable for surface and inner bore laser cladding and hardening.

- Compact and easy to maintain, delivering fine cladding surfaces with excellent forming quality.

-

Powder Feeder

- Available in standard, dual-barrel, compact, and mechanical types.

- Features touch-screen or mechanical button control, remote operation, and optional heating, dehumidifying, and stirring functions.

-

Chiller

- Internal circulation system for cooling and maintaining stable temperatures.

- Ensures consistent laser performance in high or low-temperature environments.

Applications

- Parts Repair: Enhance the lifespan and performance of worn mechanical components.

- Mold Processing: Provide high-quality surface treatments to extend mold durability.

- Industrial Manufacturing: Adaptable for batch processing of complex workpieces.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR