0 Preface TC4 Titanium alloy is a typical α+β type dual-phase titanium alloy featuring low density, high specific strength, and excellent corrosion resistance. Its superior overall performance makes it widely utilized in various ...

Contact Us

0 Preface

TC4 Titanium alloy is a typical α+β type dual-phase titanium alloy featuring low density, high specific strength, and excellent corrosion resistance. Its superior overall performance makes it widely utilized in various fields such as aerospace, marine engineering, petroleum chemical industry, and weapons equipment.The melting point of titanium alloy is high, thermal conductivity is low, elastic modulus is low, and high-temperature activity is strong. Welding processing can easily lead to a decrease in joint plasticity, joint embrittlement, etc., severely affecting the service performance of the titanium alloy joint.

At present, titanium alloy welding mainly uses methods such as tungsten inert gas welding, gas tungsten arc welding, electron beam welding, and laser welding.Tungsten inert gas welding and gas tungsten arc welding are simple to operate, low in cost, and flexible. However, they have low heat source density and slow welding speed, leading to issues such as large heat input, severe deformation, and low welding efficiency.Although electron beam welding can avoid the problem of joint embrittlement by being carried out in a vacuum environment, providing a higher quality of welded joints, its widespread application is hampered due to the limitations on the size of the welding components.Laser welding has concentrated energy and a narrow heat-affected zone, and it is not limited by the size of the components. However, the weld seam has poor tolerance to the gap and form of the groove, resulting in high precision requirements for the jig and fixture.

Therefore, this paper systematically studies the microstructure, hardness distribution, tensile properties, and electrochemical corrosion properties of the 3 mm thick TC4 titanium alloy laser-MIG hybrid welded joint. It provides reference and lessons for the application of laser-MIG hybrid welding technology in titanium alloy welding manufacturing.

1 Test materials and methods

1.1 Test materials

The experiment used 4 mm thick TC4 titanium alloy plates, processed in an I-shaped groove, without leaving a gap in the weld seam.The filler material used was 1.2 mm TC4 titanium alloy welding wire. The chemical composition of the experimental base material and filler material is shown in Table 1.Before welding, the oxide film on the surface of the titanium alloy material was removed by mechanical grinding, and then the oil stains on the surface of the titanium alloy were removed by wiping with acetone.

Table 1 Chemical composition of base material and filler wire(wt.%)

|

Material |

Ti |

Al |

V |

Fe |

N |

C |

O |

H |

Others |

|

base material |

matrix |

6.09 |

4.05 |

0.115 |

0.002 |

0.001 |

0.102 |

0.002 |

<0.30 |

|

Welding wire |

matrix |

6.24 |

4.07 |

0.048 |

0.011 |

0.006 |

0.085 |

0.0012 |

<0.40 |

1.2 Welding method

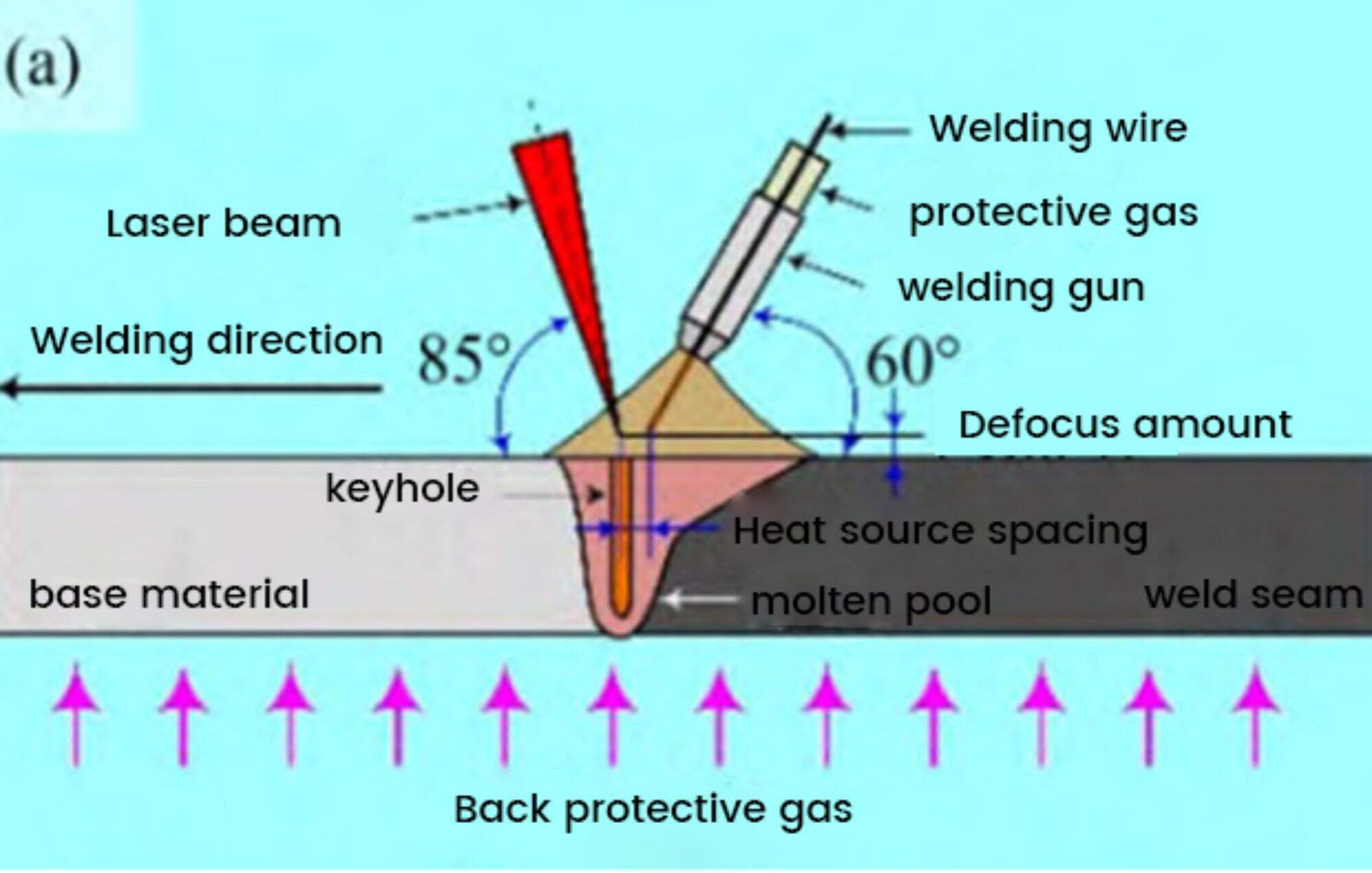

The experiment used a TRUMPF TruDisk 16003 disk laser, with a wavelength of 1.06 μm; the arc welding power supply used a FRONIUS TPS 5000 welding machine.The welding process used a heat source coupling method with the laser in front and the arc in the back. The angle between the laser and the test plate was 85°, and the angle between the welding gun and the test plate was 60°. The distance between the heat sources was 3 mm.To prevent oxidation of the weld surface, both the back and the front of the weld are protected with high purity argon gas. The flow rate of the protective gas on the front side of the weld is 50 L/min, and on the back side of the weld is 20 L/min.The schematic of the laser-arc composite welding and protective gas device are shown in Figure 1. The optimized welding process parameters are shown in Table 2.

(a)Welding devices and methods

(b)Protective gas device

Fig. 1 Protective gas device and schematic diagram of laser-MIG hybrid welding

|

Welding speed/(m·min-1) |

Laser power/kW |

Welding current/A |

Spot diameter/mm |

Defocus/mm |

|

2.5 |

4.0 |

127 |

0.6 |

+2 |

Table 2 Optimized laser-MIG hybrid welding parameters

1.3 Test methods

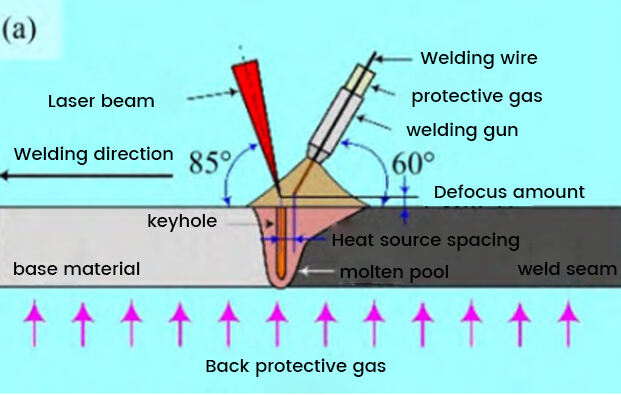

Using the KEYENCE VHX-1000E three-dimensional video microscope to observe the macroscopic morphology and microscopic structure of the welded joint;The hardness distribution of the welded joint is measured by the FM-700 micro hardness tester with a loading load of 200 gf and a holding time of 15 seconds. The tensile properties of the welded joint were tested with the WDW-300E electronic universal testing machine, and the tensile loading speed was 2 mm/min.Using an electrochemical workstation, the polarization curves of the base material and welded joints are tested with a calomel electrode and a platinum electrode as the reference electrode and auxiliary electrode;Using the ZEISS SUPRA55 scanning electron microscope, observe the microscopic morphology of the tensile specimen's fracture. The metallographic and cutting position of the tensile specimen and the size of the tensile specimen are shown in Figure 2.

(a)Sampling positions of metallographic and tensile specimens

(b)Tensile specimen dimensions

Fig. 2 Schematic diagrams of sampling positions and tensile specimen size

2 Test results and analysis

2.1 Macromorphology and microstructure of welded joints

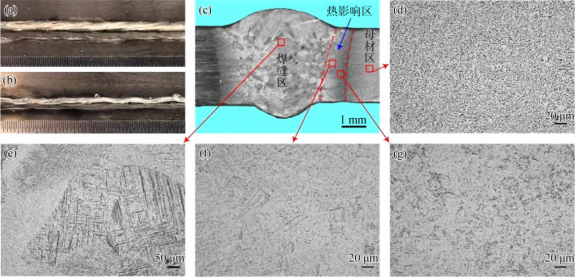

The macroscopic morphology and microscopic structure features of the TC4 titanium alloy laser-MIG hybrid welded joint are shown in Figure 3.The test results show that the front and back of the weld form good quality, with no obvious welding defects. The surface of the weld appears to be silver-white, as shown in Figure 3a and 3b;The cross-section of the weld does not have obvious defects such as pores, non-fusion, and undercut, as shown in Figure 3c.The microscopic structure of the TC4 titanium alloy base material is equiaxed α phase + β phase; the β phase is evenly distributed around the α phase grain boundaries, as shown in Figure 3d.The microstructure at the center of the weld is mainly composed of large β phase columnar crystals. The grain boundaries of the columnar crystals are intact and clear, and the interior of the grain boundaries contains interwoven basket-like fine α' martensite, as shown in Figure 3e.

(a) Formation of the front side of the weld; (b) Formation of the back side of the weld;(c) Formation of the cross-section of the weld;(d) Structure of the base metal;

(e) Structure of the center of the weld; (f) Structure of the coarse-grained area of the heat-affected zone ;(g) Microstructure of fine-grained zone in heat-affected zone

Fig. 3 Welded appearances and microstructure characteristics of laser-MIG hybrid welded joint of TC4 titanium alloy

This is mainly because during the welding process, when the weld metal is heated to above the phase transition point temperature, it cools quickly. The alloying elements do not have time to diffuse, causing the high-temperature β phase to transform into the α phase without sufficient time for diffusion, and thus leading to the non-diffusive transformation, i.e., the shear-generated α' martensite.The heat-affected zone includes two areas: the coarse-grained area and the fine-grained area. The coarse-grained area is near the fusion line, while the fine-grained area is near the base material.The microstructure of the heat-affected zone mainly consists of equiaxed α phase + β phase + α' martensite. The distribution of these phases is not uniform, with larger grains in the coarse-grained zone near the fusion line,The needle-like α' martensite is relatively more and denser, while the grains in the fine-grained zone near the base material are smaller and the needle-like α' martensite is relatively less, as shown in Figure 3f and Figure 3g,this is mainly because the heat-affected zone far away from the fusion line is less affected by the heat source, has a relatively slower cooling speed, and fewer β phase transformations into martensite. Moreover, there is a relatively shorter dwell time at high temperatures, decreasing both the propensity and the kinetics for grain growth.

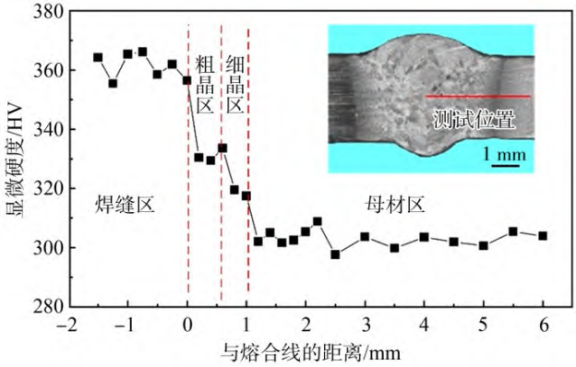

2.2 Hardness distribution

The microhardness distribution of the TC4 titanium alloy laser-MIG composite weld joint is shown in Figure 4.The test results show that the hardness value in the weld zone is the highest, followed by the heat-affected zone, with the base material zone having the lowest hardness value. It was also found that the hardness of the coarse grain zone in the heat affected zone is higher than that of the fine grain zone.This is because a martensitic phase transformation occurs in the weld zone, resulting in a large amount of martensitic structures. The numerous dislocations within the martensite play a strengthening role. Meanwhile, a partial martensitic transformation occurs in the heat-affected zone, and the amount of martensite closer to the fusion line side is greater than that on the base material side.

Fig. 4 Microhardness distribution of laser-MIG hybrid welded TC4 titanium alloy joint

2.3 Tensile properties

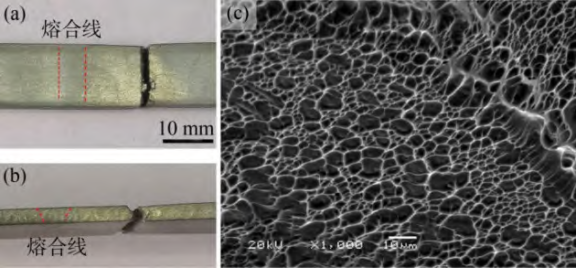

The tensile test results of the TC4 titanium alloy laser-MIG composite welded joint are shown in Table 3.The results show that the average tensile strength of the TC4 titanium alloy laser-MIG hybrid welded joint is 1069 MPa, the average elongation after fracture is 5.3%, and the samples all broke in the parent material area near the heat-affected zone.Compared with the base material, the tensile strength of the welded joint is higher than the base material, but its elongation after fracture is significantly lower than the base material. The microscopic characteristic of the fracture of the tensile sample is shown in Figure 5.The tensile sample broke at the location of the base material, which is related to the lowest hardness value in this area. The fracture path is approximately 45° to the direction of tension. The fracture morphology is mainly composed of dimples, but the size and depth of the dimples are relatively small, indicating that the fracture mainly shows plastic fracture characteristics.

|

number |

Tensile strength/MPa |

Elongation after break/% |

fracture location |

||

|

single value |

average value |

single value |

average value | ||

|

base material |

950 |

12.5 |

—— | ||

|

T-41# |

1 043 |

1 069 |

5.1 |

5.3 |

Base material area |

|

T-42# |

1 095 |

5.4 |

Base material area |

||

(a)Fracture location; (b) Fracture path; (c) Fracture morphology

2.4 Corrosion resistance

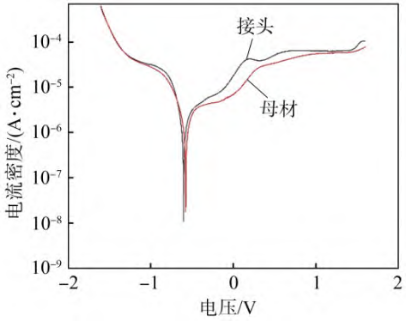

The polarization curves of TC4 titanium alloy base material and its welding joints in 3.5% NaCl solution corrosive medium are shown in Figure 6, and the parameters of the polarization curve are shown in Table 4.From Figure 6 and Table 4, it can be seen that both the TC4 titanium alloy base material and its welded joints have passivation phenomenon. The characteristic of the passivation area is that as the voltage increases, the generation of a passivation film results in current density being inhibited. The lower the corrosion potential, the easier it is to become passivated.

Fig. 6 Polarization curves of TC4 titanium alloy and its laser-MIG hybrid welded joint

|

Location |

Corrosion potential/V |

Corrosion current density/(A·cm-2) |

Open circuit voltage/V |

|

base material |

-0.591 |

0.108 |

-0.386 |

|

Welded joint |

-0.585 |

0.342 |

-0.229 |

Table 4 Corrosion potential and corrosion current density of TC4 titanium alloy and its laser-MIG hybrid welded joint

Compared to the corrosion potential of the TC4 titanium alloy base material, it has been found that it is higher than that of the welding joint. This indicates that the welding joint is more likely to undergo passivation. This also demonstrates that the corrosion resistance of the welding joint is higher than the base material. This is primarily because of the presence of acicular α' martensite in the weld structure and the formation of an oxide film on the surface of the weld seam.

3 Conclusion

(1)The weld formation obtained from the laser-MIG composite welding of TC4 titanium alloy is of high quality, with no obvious welding defects;The center of the weld mainly consists of coarse β-phase columnar crystals and intragranular α′ martensite, while the heat-affected zone primarily comprises equiaxed α-phase + β-phase + α′ martensite. Compared to the fine-grained zone close to the base material, the coarse-grained zone near the fusion line has larger grains, and the acicular α′ martensite is comparatively more plentiful and denser.

(2)The hardness is highest in the weld seam area of the welding joint, next in the heat-affected zone, and lowest in the base material area. Moreover, the hardness of the coarse-grained zone in the heat-affected area is higher than that of the fine-grained zone.

(3)The average tensile strength of the welded joint is 1069 MPa, and the average elongation after breakage is 5.3%. All samples broke in the base material area close to the heat-affected zone, and the fracture showed characteristics of a ductile break.

(4)The corrosion resistance of the welding joint is slightly higher than that of the base material, primarily due to the formation of acicular α′ martensite in the weld and the formation of an oxide film on the surface of the weld.