MAX MFSC-6000 Fiber Laser Welding Source

| Product Description |

6kW of Industrial Power. Precision Engineered. Application Versatile.

The MAX MFSC-6000 is a 6000W high-power continuous fiber laser developed for demanding industrial applications such as welding, cladding, brazing, and surface heat treatment. With its cutting-edge optical design, microsecond-level response speed, and customizable configuration, it provides unmatched performance, integration flexibility, and operational reliability.

| Key Features |

Stable Beam Quality

Precision-engineered optics ensure consistent and uniform spot profiles, delivering stable and high-quality welds across all operating conditions.Ultra-Fast Response Time

With microsecond-level response speed, the MFSC-6000 meets the needs of high-speed, high-precision manufacturing processes.High-Reliability Architecture

Designed with a high safety level and robust build, the system delivers consistent results with minimal downtime, even in 24/7 production environments.Integrated Waveform Editor

Built-in waveform editing card allows precise control of output patterns—ideal for irregular parts and complex welding paths.Superior Bus Compatibility

Supports a wide range of industrial bus protocols for seamless integration into various control systems. Customization available for specific integration needs.Customizable Core Options

Users can select different fiber core diameters according to specific material types and application requirements.

| Parameter |

| Parameter | MFSC-6000(W) |

|---|---|

| Optical Characteristics | |

| Output Power (W) | 6000 |

| Operation Mode | Continuous/Modulated |

| Polarization | Random |

| Power Adjustment Range (%) | 5~100 |

| Center Wavelength (nm) | 1080±5 |

| Spectral Bandwidth 3dB (nm) | 5~7 |

| Short-term Power Stability (%) | ±1 |

| Beam Quality BPP (mm x mrad) | 3~4 (100μm Core) |

| Laser On Time (μs) | < 50 |

| Laser Off Time (μs) | < 50 |

| Modulation Frequency (KHz) | 50 |

| Pilot Red Laser Power (μW) | ≥ 500 |

| Output Fiber Parameters | |

| Output Type | QBH/LOE |

| Fiber Cable Length (m) | 20 (Customizable) |

| Output Fiber Core Diameter (μm) | 100 (50/150/200 optional) |

| Fiber Bending Radius (mm) | ≥ 200 |

| Electrical Parameters | |

| Operating Voltage (VAC) | 400(±40) |

| Input Power (KW) | 16 |

| Other Parameters | |

| Operating Temperature (°C) | 25 (10~40) |

| Storage Temperature (°C) | -10~60 |

| Operating Humidity (%) | 10~85 |

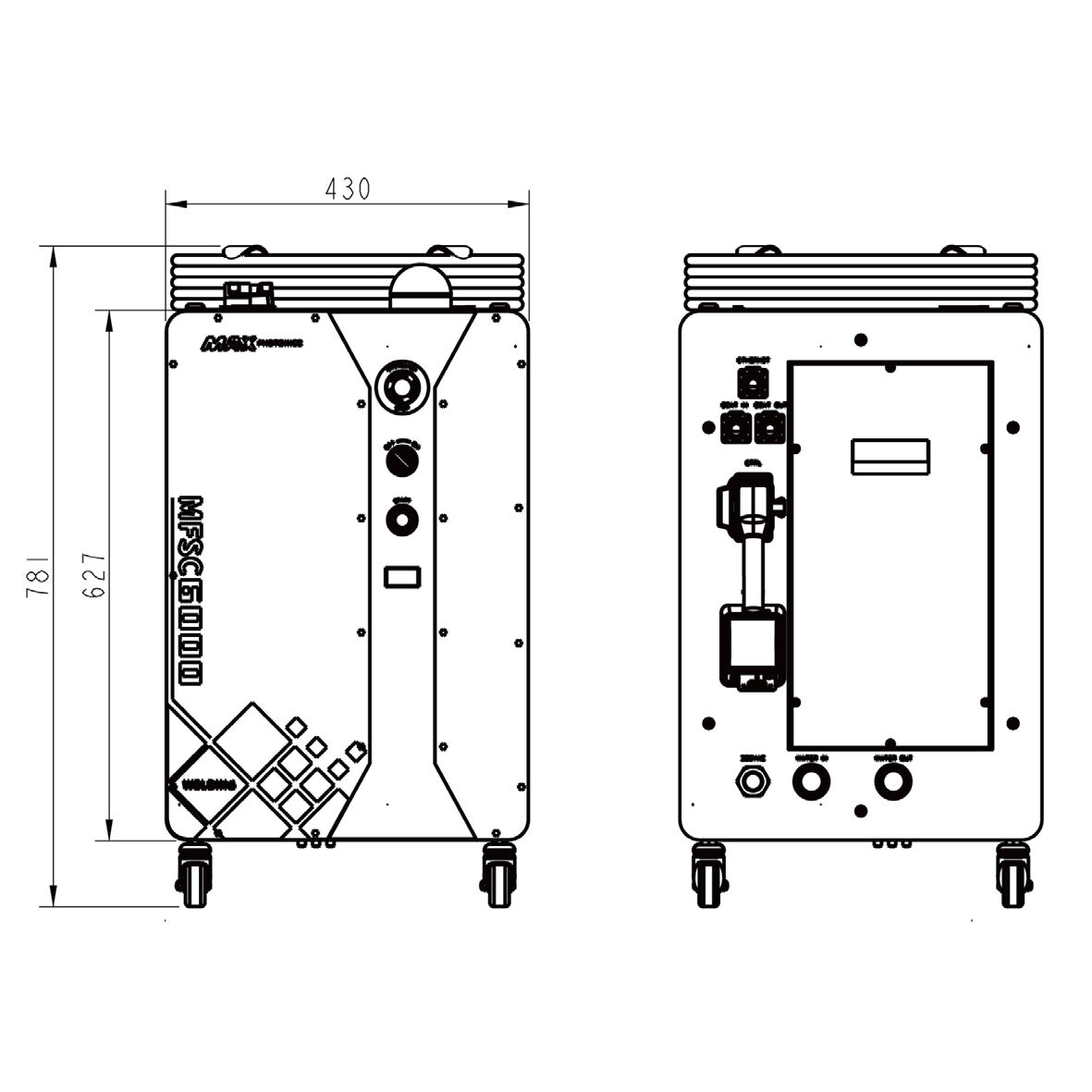

| Cooling Method | Water Cooling |

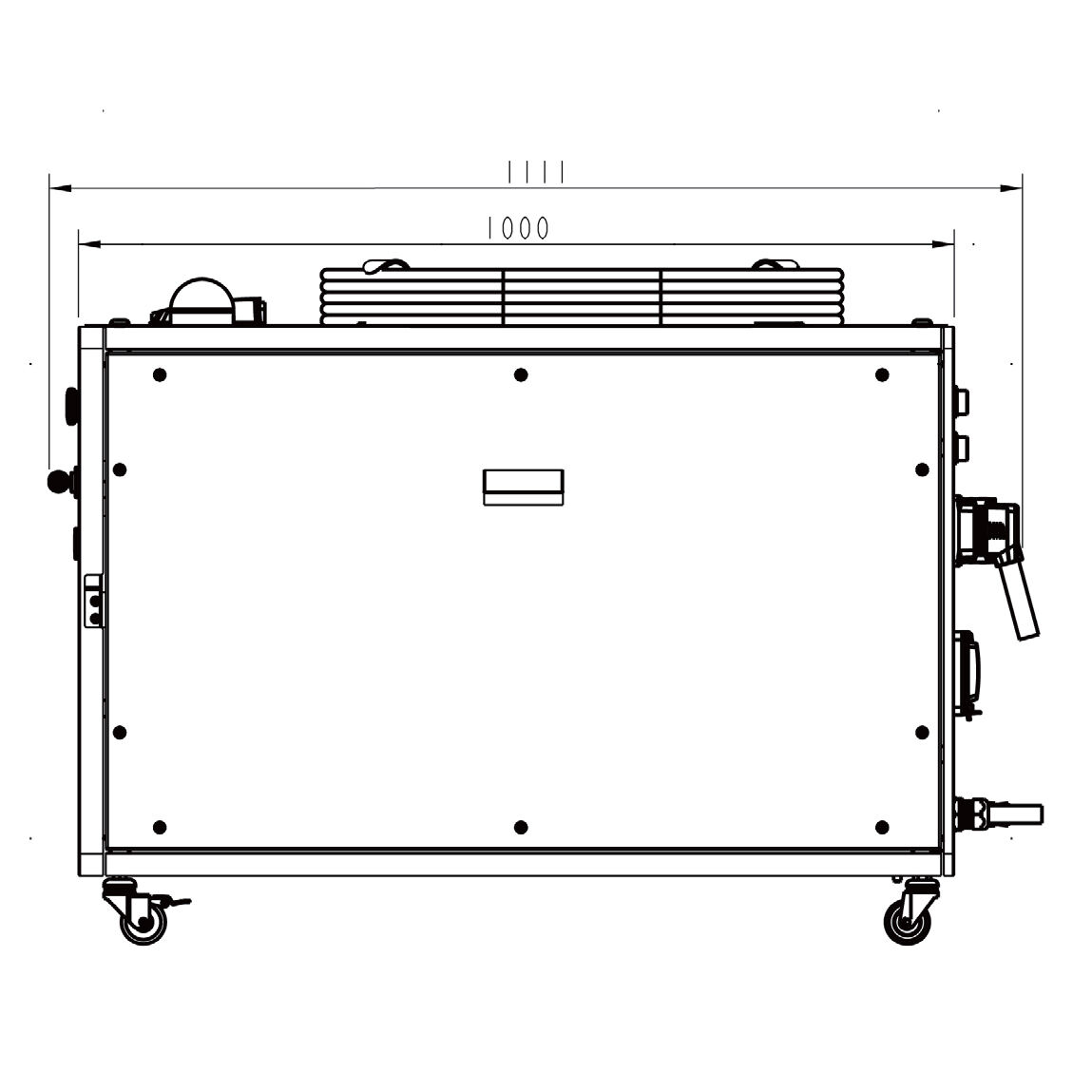

| Dimensions W×D×H (mm) | 430×1000×627 (excluding casters/indicators) |

| Weight (kg) | 150±10 |

| Application |

Laser Welding

Ideal for deep, high-strength welds across thick materials—perfect for automotive, heavy equipment, and aerospace industries.

Laser Cladding

Restores and enhances surfaces with wear- or corrosion-resistant coatings, extending equipment lifespan.

Laser Brazing

Delivers smooth, aesthetically pleasing joints, especially for dissimilar materials.

Laser Surface Heat Treatment

Precisely targets material surfaces to improve hardness and resistance without compromising structural integrity.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR