MAX MFSC-3000 Fiber Laser Welding Source

| Product Description |

High-Power Precision. Compact Design. Industrial-Grade Performance.

The MAX MFSC-3000 is a 3000W high-performance fiber laser source designed for industrial welding, cladding, brazing, and surface heat treatment applications. Engineered with cutting-edge electro-optical design and a compact, modular structure, it delivers outstanding stability, integration flexibility, and superior processing results across a wide range of materials.

| Key Features |

High Energy Density & Easy Integration

Compact rack-mountable design allows quick and seamless integration into precision machinery, automated lines, and sheet metal systems.Modular Design for Easy Maintenance

Electrical and optical modules are separated, making on-site replacements of optical paths or electrical components fast and hassle-free.Independent Pump Control Minimizes Downtime

Equipped with single-pump control technology, allowing each pump to operate independently. If one pump experiences a fault, the system can continue running with the remaining units.Superior Beam Quality & High Brightness

Small core diameter with excellent beam quality enables stronger, cleaner welds and more efficient material processing.Versatile Applications

High-power single-module configuration offers thicker material processing capabilities—supporting welding, cutting, cladding, and thermal surface treatment in one system.

| Parameter |

| Parameter | MFSC-3000(W) |

|---|---|

| Optical Characteristics | |

| Output Power (W) | 3000 |

| Operation Mode | Continuous/Modulated |

| Polarization | Random |

| Beam Quality BPP (mm x mrad) | 1.1~1.5 (50um-QBH Output) |

| Center Wavelength (nm) | 1080(±5) |

| Spectral Bandwidth 3dB (nm) | 4~6 |

| Power Adjustment Range (%) | 10~100 |

| Short-term Power Stability (%) | ±1.5 |

| Laser On Time (μs) | 50~100 |

| Laser Off Time (μs) | 50~100 |

| Modulation Frequency (KHz) | 20 |

| Pilot Red Laser Power (μW) | 200 |

| Output Fiber Parameters | |

| Output Type | Standard QBH(LOC) |

| Fiber Cable Length (m) | 20 (Customizable) |

| Output Fiber Core Diameter (μm) | 50 (100/200 optional) |

| Fiber Bending Radius (mm) | 200 |

| Electrical Parameters | |

| Operating Voltage (VAC) | 400(±40) |

| Input Power (KW) | 10 |

| Other Parameters | |

| Operating Temperature (°C) | 25 (10~40) |

| Operating Humidity (%) | 10~85 |

| Storage Temperature (°C) | 25 (-10~60) |

| Cooling Method | Water Cooling |

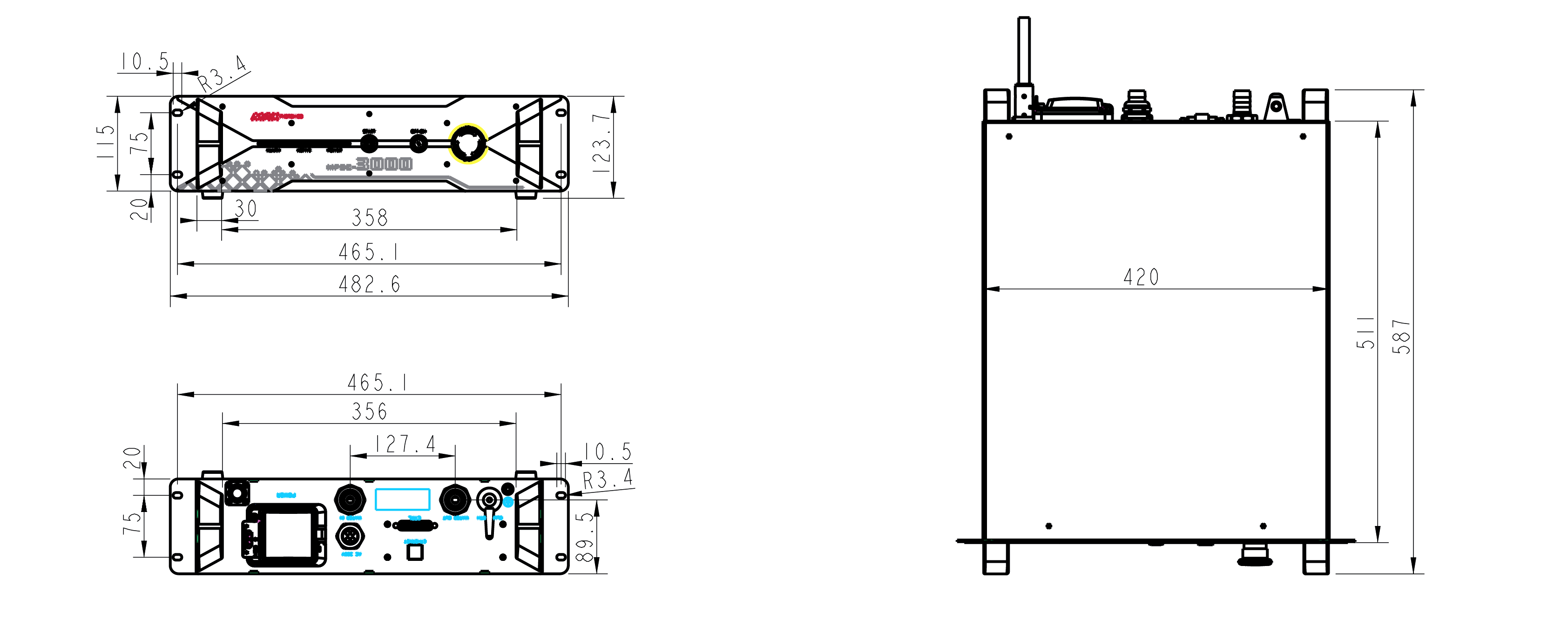

| Dimensions (mm) | W×D×H: 420×587×115 |

| Weight (kg) | 35.5(±2) |

| Application |

Laser Welding: High-strength weld seams on stainless steel, carbon steel, aluminum, and other metals.

Laser Cladding: Surface coating of mechanical parts for wear and corrosion resistance.

Laser Brazing: Precise joining of dissimilar materials without melting the base metal.

Laser Surface Heat Treatment: Targeted thermal processing to enhance material hardness and durability.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR