KRD 800W Water-Cooled Handheld Welding Machine for Thin Plates

Product Introduction

The KRD thin plate welding machine is a water-cooled laser welding device specifically designed for welding metal thin plates with a thickness of less than 0.8mm. This model integrates an all-in-one cabinet, fiber laser, laser control system, and handheld welding head, and is widely used in metal advertising word welding, stainless steel engineering welding, thin plate cabinet welding, and large thin plate structure welding.

Product Features

① Fast welding speed, 2-10 times faster than traditional welding, saving at least two welders' costs per year with one machine.

② Fewer laser welding consumables and long service life.

③ Simple operation, no work certificate required; even untrained personnel can weld beautiful products.

④ Smooth and aesthetically pleasing welds, reducing subsequent grinding processes and saving time and costs.

⑤ No welding deformation, no obvious scars, and firm welding.

⑥ Safer and more environmentally friendly.

⑦ Independently developed mixing welding head compensates for the disadvantages of laser welding spots, expands the tolerance range and welding width of processed parts, and achieves better weld formation.

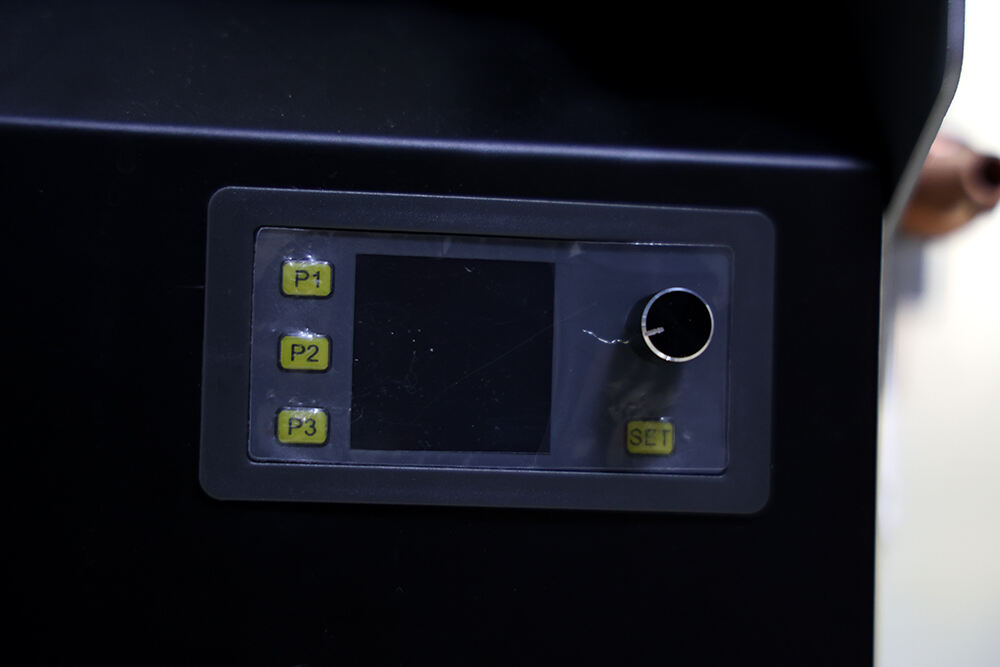

⑧ Integrated cabinet design, combining laser, software control, and other features, offering unique advantages of small footprint, convenient mobility, and strong functionality.

⑨ Handheld welding head equipped with 5m-10m original optical fiber for flexibility and convenience.

⑩ Handheld operation mode, with special welding nozzles allowing for welding at any angle on any part.

⑪ Suitable for block welding, overlapping welding, internal and external corner welding, circular arc welding, and irregular shape welding.

⑫ Exclusive laser safety operation protection function to ensure the safety of operators during work.

|

|

|

|

|

|

Applicable Industries

The KRD thin plate welding machine is widely used in the following industries:

- Electronics Industry: Welding electronic components and circuit boards to ensure stable and reliable connections.

- Automotive Manufacturing: Welding lightweight metal parts in the production of automotive components to enhance overall structural strength.

- Home Appliances: Welding thin metal shells for home appliances such as refrigerators and washing machines.

- Metal Advertising Industry: Welding metal advertising signs and logos to meet aesthetic and durability requirements.

- Aerospace: Welding thin metal parts in lightweight designs to ensure safety and performance.

- Medical Equipment: Welding thin metal structures for medical devices to guarantee precision and safety.

- Furniture Manufacturing: Welding thin metal furniture, such as metal chairs and tables, to enhance product aesthetics and stability.

|

|

|

|

|

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR