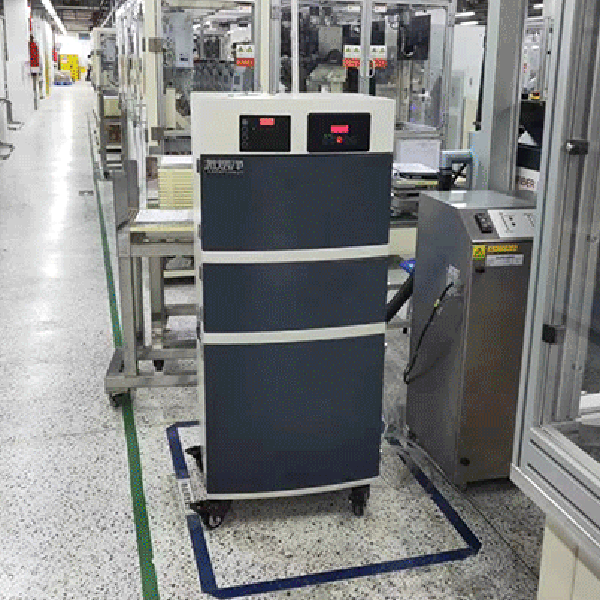

High Negative Pressure Laser Welding Fume Extractor

| Product Description |

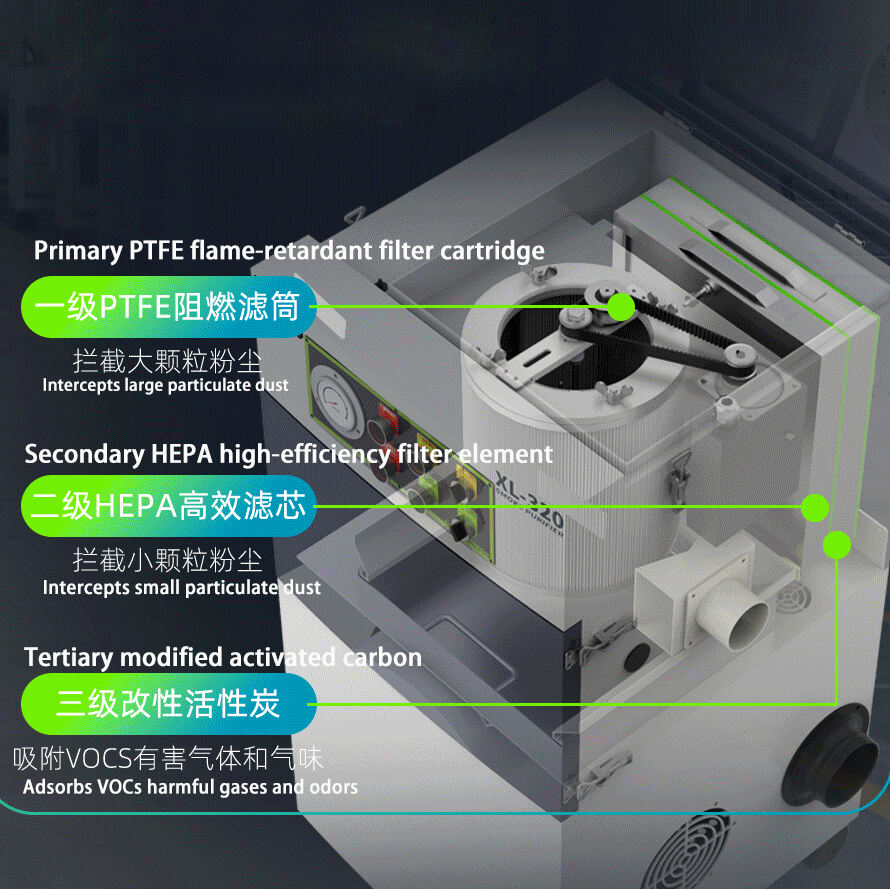

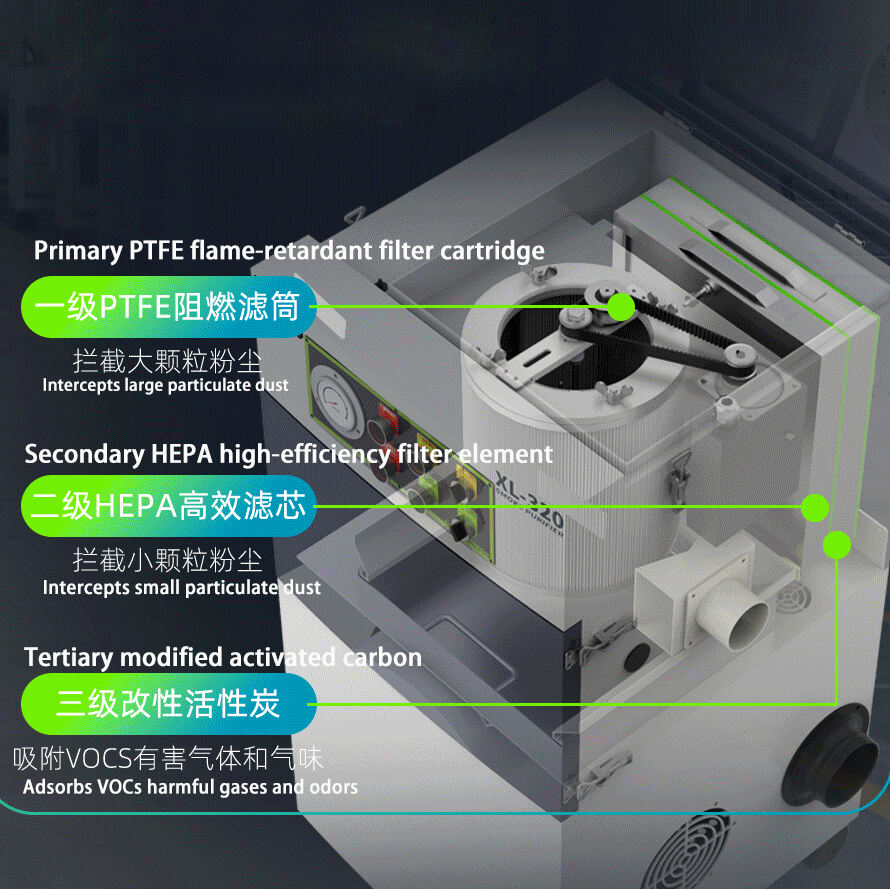

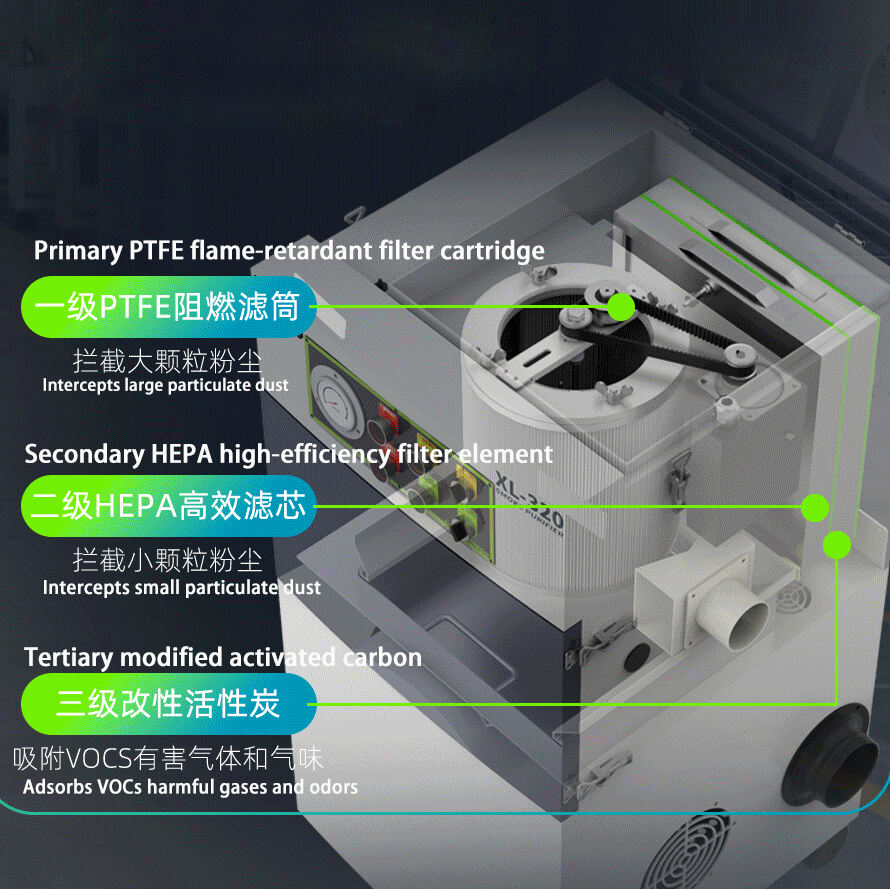

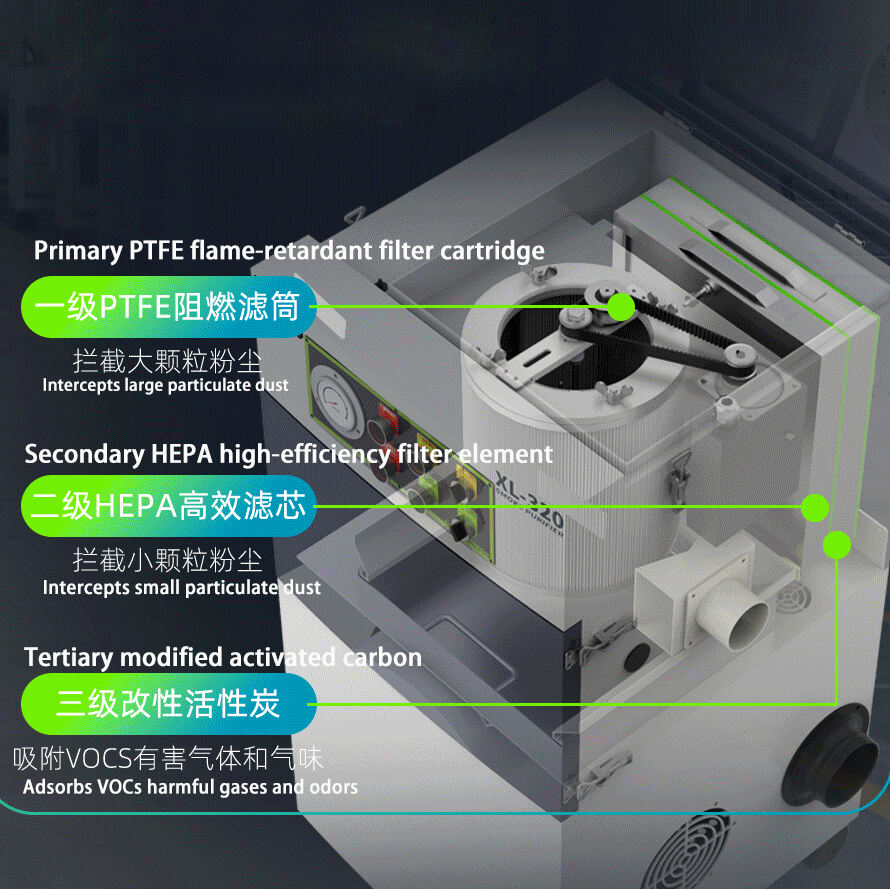

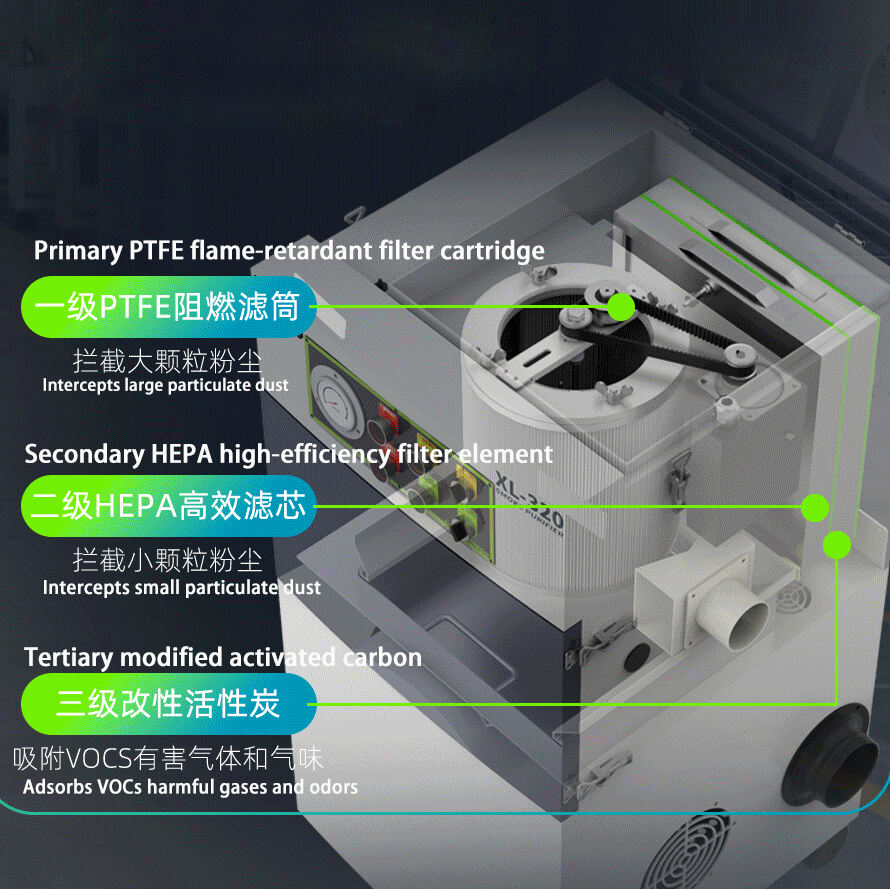

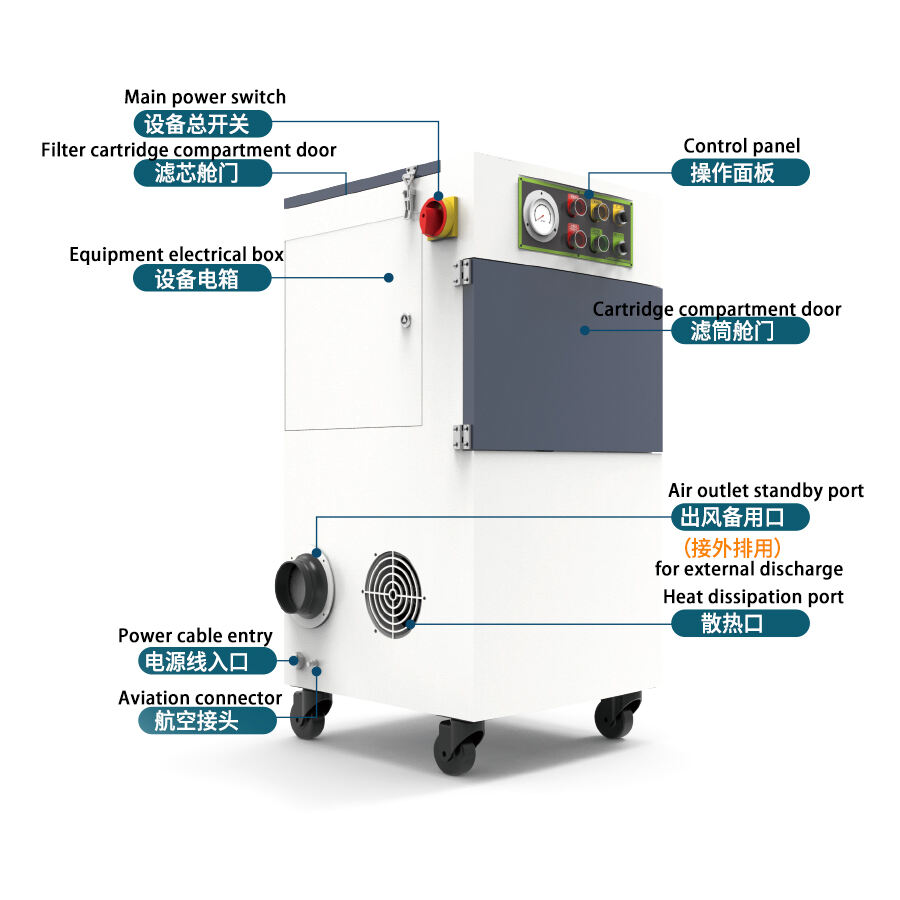

This high negative pressure fume extractor is specifically engineered for laser welding, cutting, and cleaning processes. It delivers powerful suction and efficient filtration with a compact design, ensuring a cleaner and safer workspace. The triple-layer filter system, combined with an automatic electric dust-cleaning function, guarantees long-term performance without the need for compressed air. Even during cleaning cycles, the extractor continues operating—no downtime, no dust leakage, just consistent reliability.

| Key Features |

Triple-layer Filter Cartridge: Multi-stage filtration ensures high dust capture efficiency. |

|

|

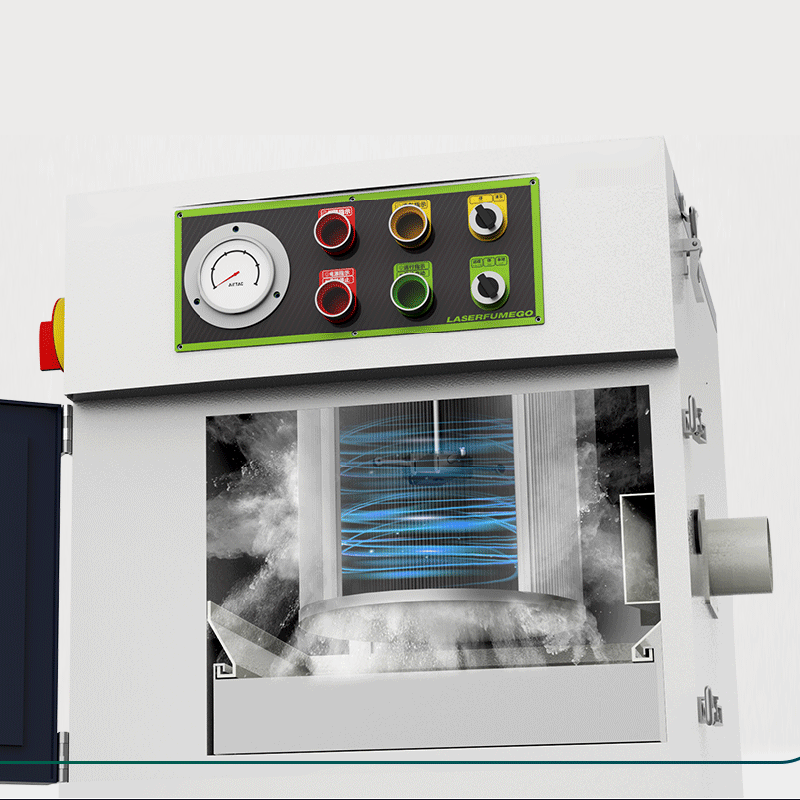

Automatic Electric Dust Cleaning: No compressed air required; safe and dust-free cleaning process. |

Continuous Operation: Filter cleaning and fume extraction can run simultaneously. |

|

|

High Negative Pressure Fan: Optimized for 40mm and 50mm inlets; supports dual-station fume extraction. |

Motor Safety Protections: Built-in over-temperature and overload protection to prevent motor damage. |

|

|

Compact and Durable Design: Space-saving yet powerful for industrial use. |

| Parameter |

| Model | XL-220 | XL-260 | XL-320 | XL-420 | XL-480 | XL-530 |

| Power (kW) | 0.75 | 1.5 | 2.2 | 3 | 4 | 5.5 |

| Power supply (V/Hz) | 220/50Hz | 220/50Hz | 380/50HZ | 380/50HZ | 380/50HZ | 380/50HZ |

| Negative pressure (Pa) | 12000 | 18000 | 24000 | 26000 | 32000 | 35000 |

| Flow rate (m³/h) | 220 | 260 | 320 | 420 | 480 | 530 |

| Equipment dimensions (mm) | 585*555*1005 | 700*680*1200 | ||||

| Filter area (m²) | 1.5 | 3.5 | ||||

| Purification system | Three-stage filtration | Three-stage filtration | ||||

| Dust cleaning system | Automatic electric dust cleaning | Automatic electric dust cleaning | ||||

| Standard features | PLC aviation connector and filter replacement reminder | PLC aviation connector and filter replacement reminder | ||||

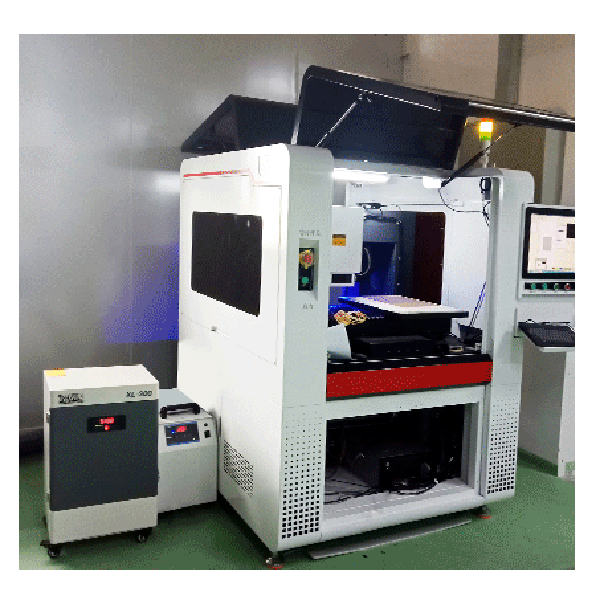

| Applications |

Laser Welding | Laser Cutting | Laser Cleaning

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR