Robot Laser Cleaning Machine

Product Description

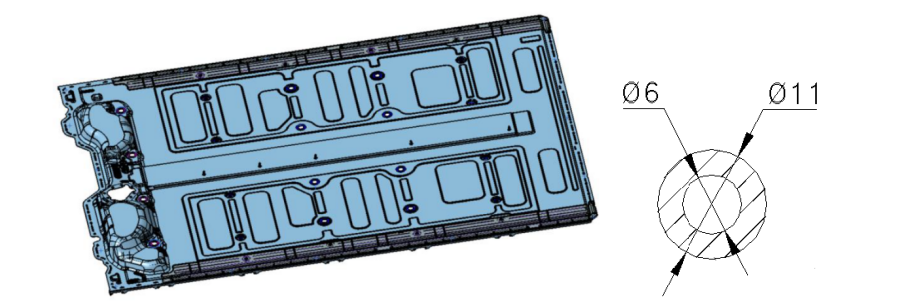

Power battery box cover coating laser cleaning applications: electric shock protection is an important element of the electrical safety design of the power battery system, battery box shell above all accessible conductive metal parts must be connected to the shell isotropically, most of the market using crimp or bolt connection method, if the bolt connection method contact surface can not be painted or insulation treatment, otherwise the contact impedance is very large, can not meet the requirements Therefore, it is necessary to remove the paint or coating from the contact surface before locking the balance bolt.

Beat: a single workpiece product to complete the entire cleaning process 196s, a single hole cleaning time of 4s.

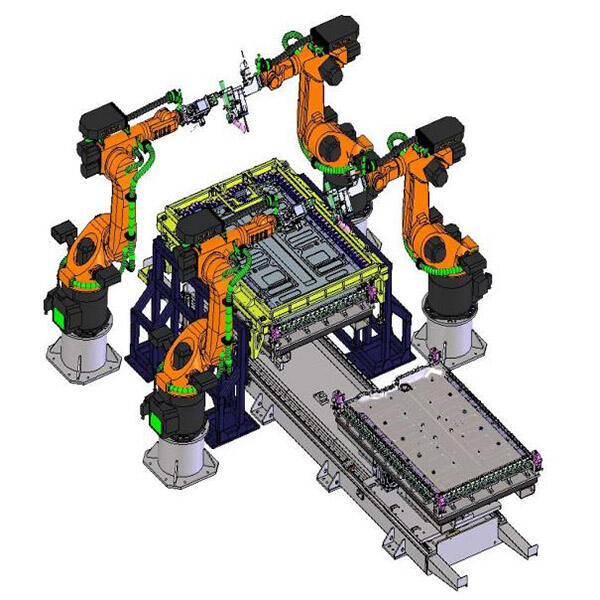

The work station is divided into transition station and cleaning station, the transition station mainly consists of loading and unloading rack, handling robot, sliding table, etc.; all the cleaning stations are carried out in the closed laser room with laser cleaning system, vision system, database storage system, cooling system, follow-on fume purification system, mobile sliding table, cleaning fixture, cleaning robot, etc.; the two sides of the room are equipped with industrial control machine, control cabinet, gas storage tank, filtration system, etc.; the periphery is equipped with monitoring system to observe the operation status of the equipment in the room in real time.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR