Automatic Laser Cleaning Machine For Mold Industry

Product Description

Automated laser cleaning machine is a new generation of high-tech products

for surface treatment and cleaning. It is not only compact, easy to robot and

CNC and other integrated devices to achieve automated processing. Customized

platforms are also available, in which the process is not only stable and

reliable but also consistent in cleaning quality. Cleaning machine can provide

external control interface, greatly improving the operability of the cleaning

machine, can also be upgraded to dust-proof chassis, can fit the surface

cleaning, can remove the object surface stubborn paint, stains, dirt, rust and

industry applications are relatively wide. For example, ship rust cleanup, in

machine tools to remove stains, auto repair to remove surface dirt, etc.

Quick Detail

The features of the automated laser cleaning machine are listed as follows:

1、Flexible front end

2、The whole machine is compact and portable easy to carry and push

3、Lightweight design of the cleaning head, compact and easy to operate

4, a variety of cleaning head options, A series and B series

5, the anti-shaking technology

6, long depth of focus design

7, air-cooled

8, can be upgraded to dust-proof chassis

Competitive Advantage

1、High degree of automation

After 2 months of 24-hour non-stop testing, the current degree of automation of Kington laser line is the highest in the industry, compared with the traditional manual cleaning method, we can start automatic cleaning by pressing the button, easy and convenient.

2、High efficiency

In the cleaning, we found that the cleaning speed of Kington laser than other factories of the same type of automated cleaning machine efficiency is 10 minutes / vice, compared to the traditional manual cleaning method, the efficiency has doubled, and now become the fastest intelligent cleaning machine inside the cleaning record, so that we can save one person per shift cleaning labor time costs, three shifts to save three people.

3、Cleaning clean

The whole cleaning process of industrial robots drive the end-effector to keep moving at high speed, we check the cleaned mold through the optical amplifier, no pollutants, no material substrate damage."

4.High quality pre-sales service

We provide you with relevant technical support and product industry information, provide you with free proofing and other related facilities. Tailor-made models, so that your use of

more satisfying.

5. Outstanding after-sales service

We provide you with professional after-sales guarantee, two-year warranty for the whole machine, lifelong maintenance, free technical consultation, 24-hour answer to customer questions, national door-to-door

Installation training.

6. Scope of application of the machine

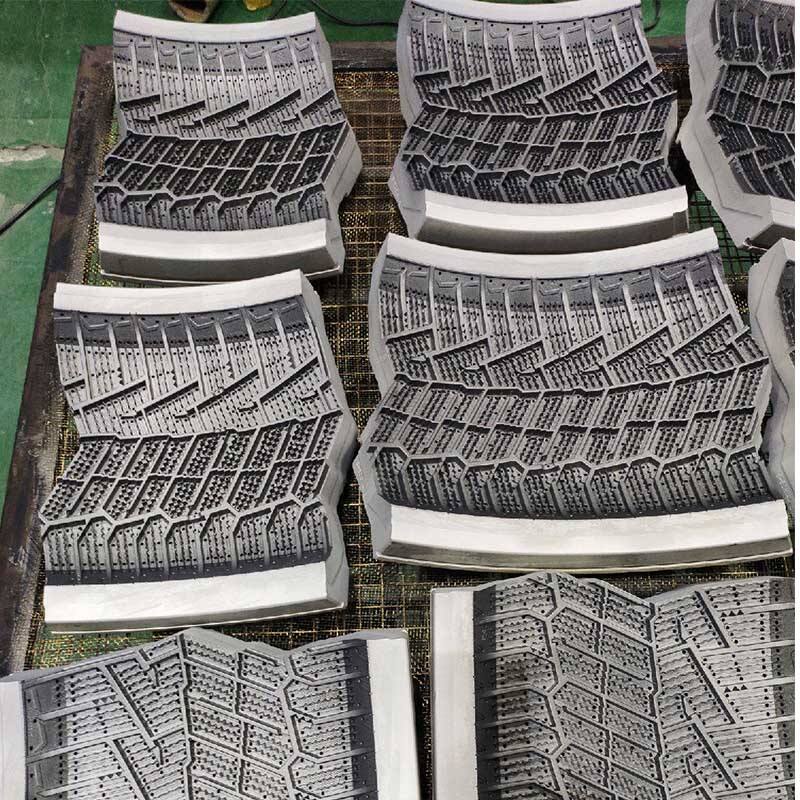

Use industry: auto parts rubber mold high-end machine tools tire mold track environmental protection industry

Scope of application: laser paint removal, laser oil removal, laser removal of oxide layer, laser cleaning screw, tire mold cleaning, etc.

7. Machine delivery process

Shipping time to the signed supply and sales contract time shall prevail (note the contract time)

Machinery and equipment for large products, shipping logistics, buyers in the receipt of goods, be sure to open the box to check the condition of the equipment. The equipment found after signing the receipt due to transportation

Scratch damage found after receipt (the time of receipt is subject to the logistics information), not in the scope of responsibility, please know!

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR