Automatic Laser Rust Removal System

Product Description

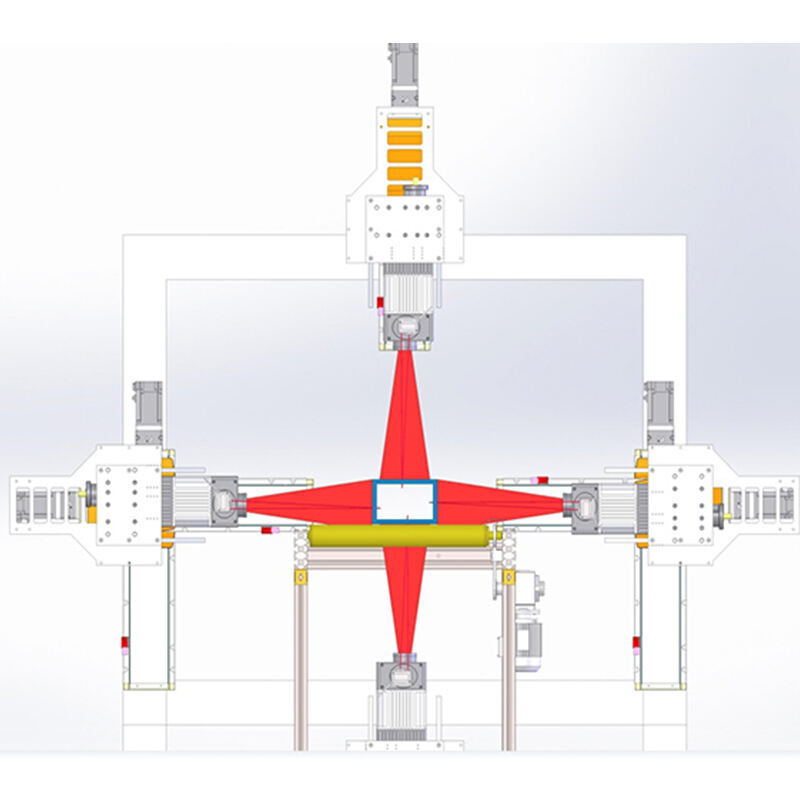

Object of cleaning: The wheel pair surface varnish coating and rust and oil stains of moving wheels and trailers.

Cleaning requirements: 1) Remove varnish coating (80-120μm) and rust and oil from the wheel pair surface, the moving wheel pair is required to avoid the gear box, coupling and journal (yellow wire frame area), the trailer wheel pair cleans the overall surface; the damping ring installation of the moving car and trailer does not require paint stripping and rust removal (red wire frame area), and is removed at the subsequent wheel pair axle grinding; 2) reveal the silver-white metal surface after cleaning, single wheel pair The time for paint stripping and rust removal is about 0.5h.

Technical Solution Introduction

The wheel pair laser cleaning machine (workstation) includes laser cleaning mainframe, mechanical arm, mechanical arm track and supporting gantry, wheel pair lifting and driving device, automatic loading and unloading assembly, fume and dust purification system, control unit, workstation outer cover, voltage stabilized power supply and other auxiliary equipment.

Among them, the staff can operate on the touch screen of the control unit on the left side of the wheel pair cleaning workstation to give the start command; meanwhile, through the auxiliary equipment (video monitoring component in the workstation), the staff can directly observe the cleaning situation screen in the station in real time on the monitoring screen.

The middle of the workstation is the cleaning area, which is a closed space constituted by the outer cover of the workstation and the special door of the logistics channel set before and after (the door drops closed when automatic cleaning).

Through the above way, laser cleaning wheel on the surface of the paint, rust and oil in the process of smoke and dust odor, after the workstation on the left side of the fume and dust purification system, through the overall closed and localized with the precise collection of dust, can be directly discharged through the exhaust port to the workstation outside: this, on the one hand, to avoid the health risks of smoke and dust odor dust escaping to the workshop plant inhaled by personnel, on the other hand, also through the cleaning area and On the other hand, the division between the cleaning area and the operating area protects the safety of personnel during operation.

Specifications

The main components of this laser cleaning workstation are shown in the table below.

| Serial number | Name | Factory | Remarks |

| 1 | Laser cleaning host | DMK | |

| 2 | Robotic arm | Yasukawa | Includes 1 external robot axis |

| 3 | Mechanical arm track and supporting support gantry | DMK | |

| 4 | Wheel pair lift and drive device | DMK | |

| 5 | Automatic loading and unloading device | DMK | |

| 6 | Control unit | DMK | |

| 7 | Workstation cover | DMK | |

| 8 | Auxiliary equipment | DMK | Video Surveillance Components |

| 9 | Fume cleaning system | JYJ | Workstation fume extraction equipment |

Table 3-1 Detailed project configuration list

Automatic laser rust removal system

Automatic laser rust removal system

Automatic laser rust removal system

Applications

Preparation work before the start of the laser cleaning pair: including checking the cleanliness of the front lens of the laser cleaning gun, whether the emergency stop button of the equipment is popped up, whether the control system has been turned on normally, whether there is an alarm, etc.. After confirming that there is no error, start the equipment to start cleaning.

Automatic cleaning action process:

1) Staff push the wheel pair to a specific waiting position outside the cleaning room and start the equipment in the operation area.

2)The loading entrance door opens, the automatic loading and unloading mechanism moves below the wheel pair in the waiting area, and the clamping jaws rise up to clamp the wheel axle. The automatic loading and unloading mechanism pushes the wheel pair to the cleaning operation position. At the same time, the automatic type identification device of the equipment identifies the wheel pair and judges the wheel pair type and gear box position.

3)The loading entrance door is closed to ensure closed operation. The lifting device lifts the wheel pair up and off the track, and the auxiliary automatic positioning detection device detects the lifting position to improve the positioning accuracy.

4)The automatic loading and unloading device jaws are returned downward, and the drive unit drives the wheel pair to rotate. The robot is automatically positioned and the laser starts automatic cleaning until all positions are cleaned. At the same time, the fume purifier starts operation to ensure the collection of operation dust.

5)The automatic loading and unloading device jaws extend upward, the lifting device descends, and the wheel pair is placed back on the rail. The exit door of the lower material is opened, and the automatic loading and unloading device pushes the wheel pair to the lower material area. The loading and unloading mechanism is retracted downward and returned to the workstation, the exit door is closed and the automatic cleaning process is completed.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR