Mold Repair YAG Laser Welding Machine

| Product Description | ||||

|

|

|

|

| Advantage |

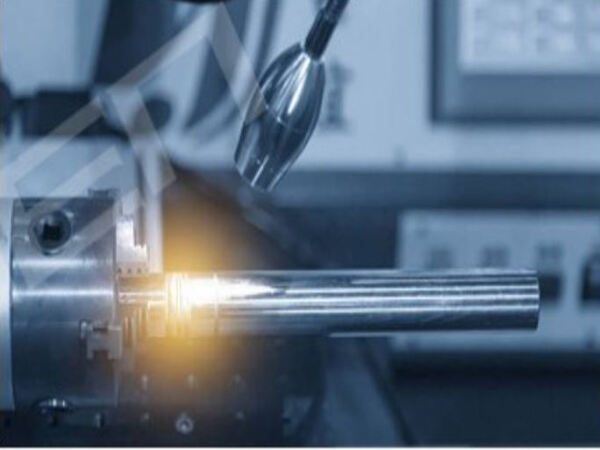

| Specifically designed for the mold industry, it adopts a unique structural design and is suitable for repairing various large, medium and small molds. | |

|

1. It adopts ceramic focusing cavity imported from the UK, which is corrosion-resistant and high-temperature resistant. The cavity life is (8-10) years, and the xenon lamp life is more than 8 million times. 2. The world's most advanced automatic shading system is adopted to eliminate eye irritation during working hours. 3. The laser head can rotate 360 degrees, and the entire optical path can rotate 360 degrees. It can also be electrically lifted up and down, and pushed forward and backward. It is especially suitable for repairing various large, medium and small molds. |

| 4. Parameter adjustment is controlled by an intelligent remote control, making the operation simple and fast. 5. The workbench can be lifted and lowered electrically. 6. The light spot size is electrically adjusted. |

|

| Specification |

|

Product model

|

DYH-200

|

DYH-300

|

DYH-400

|

DYH-600

|

|

Maximum laser power

|

220W

|

350W

|

450W

|

600W

|

|

Maximum single pulse energy

|

60J

|

80J

|

90J

|

110J

|

|

Laser wavelength

|

1064nm

|

1064nm

|

1064nm

|

1064nm

|

|

Wave structure

|

Single pulse

|

Double pulse combination

|

Double pulse combination

|

Double pulse combination

|

|

Welding depth

|

0.5mm

|

0.8mm

|

1.0mm

|

1.5mm

|

|

Pulse Width

|

0.2-2.0mm

|

0.2-2.0mm

|

0.2-2.0mm

|

0.2-2.0mm

|

|

Welding frequency

|

100Hz

|

100Hz

|

100Hz

|

100Hz

|

|

Spot adjustment range

|

0.2-3.0mm

|

0.2-3.0mm

|

0.2-3.0mm

|

0.2-3.0mm

|

|

Fiber length

|

3m/5m/10m/20m

|

3m/5m/10m/20m

|

3m/5m/10m/20m

|

3m/5m/10m/20m

|

|

Total power

|

9KW

|

12KW

|

16KW

|

18KW

|

|

Power demand

|

AC 220V/50HZ

|

AC 380V/50HZ

|

AC 380V/50HZ

|

AC 380V/50HZ

|

| Application |

|

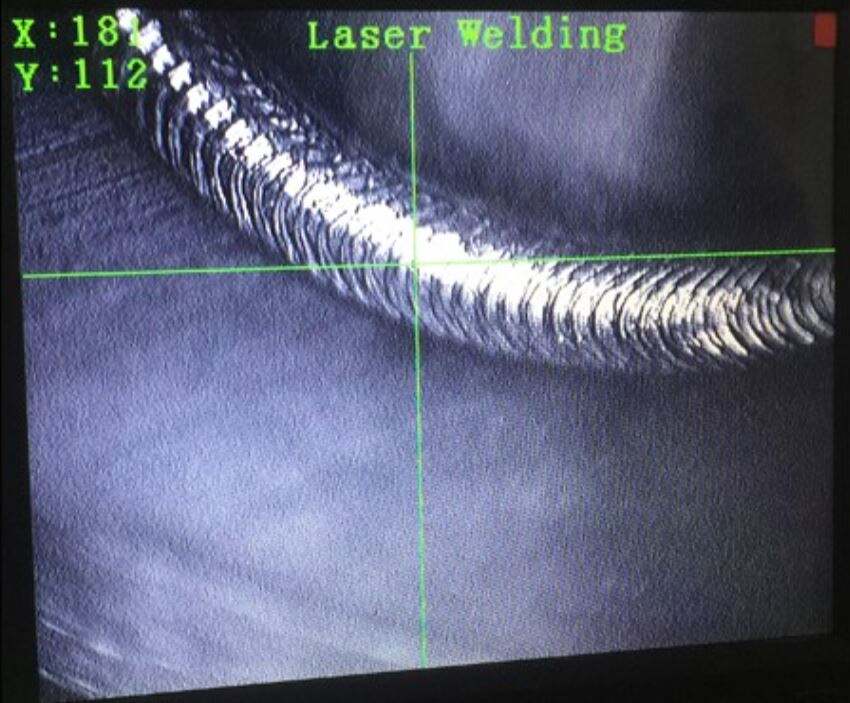

Repair molds, repair welding of defective surfaces |

repair cracks, spot welding of metal flakes |

welding of handicrafts, small parts, jewelry, watches |

|

Applicable materials. Mold laser welding machine is suitable for welding of gold, silver, titanium, nickel, tin, copper, aluminum and other metal and its alloy material, can achieve the same precision welding between metal and dissimilar metals, has been widely used in aerospace equipment, shipbuilding, instrumentation, mechanical and electrical products, automotive,various metal letters, stainless steel letters, LED luminous characters, AD Logos, customized metal signage and exterior billboards and other industries. Application Industry.Mould laser welding machine was originally designed for mould industry for molding and repairing of plastic molds, die-casting molds, extrusion molds, glass molds, plastic blow molds, rubber molds, molds of digital products / mobile phone / toy / automobile / motorcycle / etc. By applying suitable soldering wires, it is possible to fill the crack or blowholes and reuse the mold which saves production cost and improves working efficiency significantly. General laser mould welder also can be used in metal sheet stitching welding, pipe/ tube conjunction welding, and manufacturing of sensor, level switch and fine auto parts, etc.

|

||

| Company Profile |

Q: What materials can be welded using the Mold Repair YAG Laser Welding Machine?

A: The machine can weld various types of metals, including steel, stainless steel, copper, aluminum, and titanium.

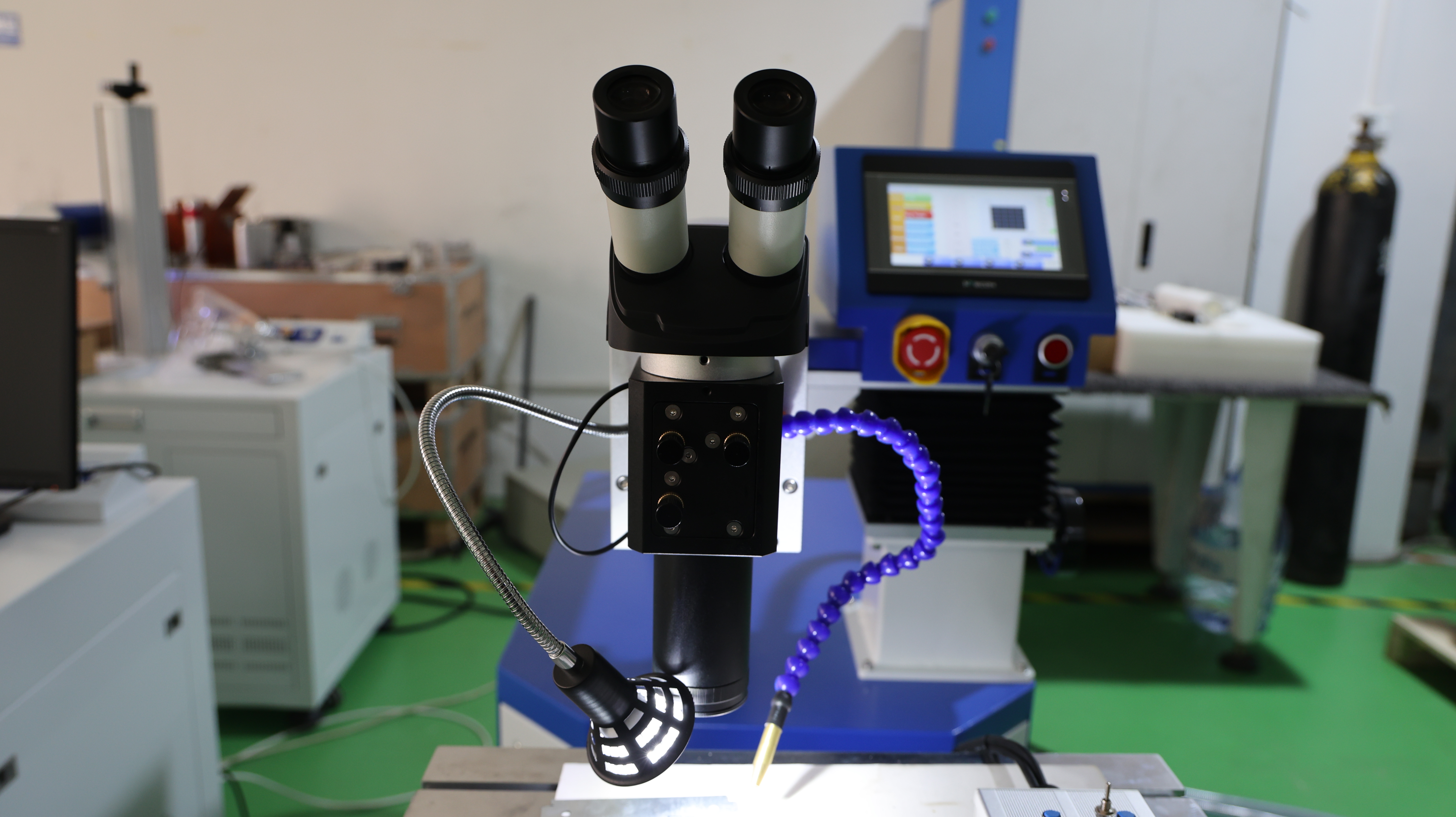

Q: How does the machine ensure precision welding?

A: The machine is equipped with a galvanometer scanning system, which provides accurate positioning and fast welding speed. The laser welding head is also equipped with a microscope, which offers a clear view of the welding area for precise operation.

Q: How long does it take to complete a typical welding job using the Mold Repair YAG Laser Welding Machine?

A: The time required to complete a welding job depends on various factors, such as the size of the welding area, the type of metal being welded, and the desired welding parameters. However, the machine's high welding speed can significantly reduce the time required to complete a job.

Q: Is the machine easy to operate?

A: Yes, the machine is designed with a user-friendly interface and a digital control system, which allows operators to adjust the welding parameters easily. The machine is also equipped with a microscope, which offers a clear view of the welding area for precise operation.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR