Laser Welding Positioner

| Product Description |

| The positioner is a welding auxiliary equipment, which is suitable for the welding position of the rotary work to obtain the ideal processing position and welding speed. It can be used with laser welding machine to form an automatic welding center, and can also be used for workpiece displacement during manual operation. The rotation of the worktable adopts the stepless speed regulation of the frequency converter, and the speed regulation accuracy is high. The remote control box can realize the remote operation of the workbench, and can also be connected with the control system of the operating machine and the welding machine to realize the linkage operation. |

|

Single shaft head and tail frame positioner |

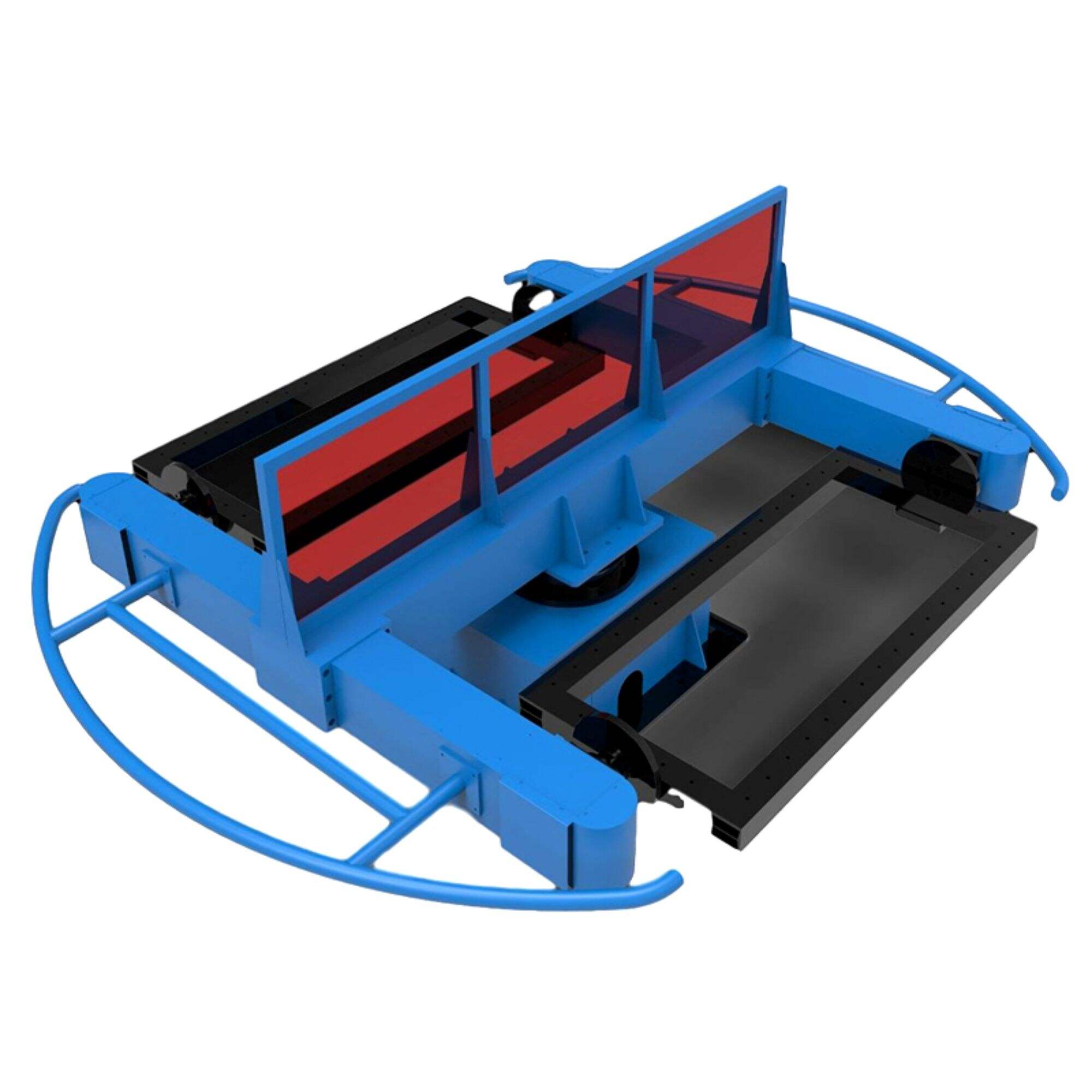

Double axis L-type positioner |

|

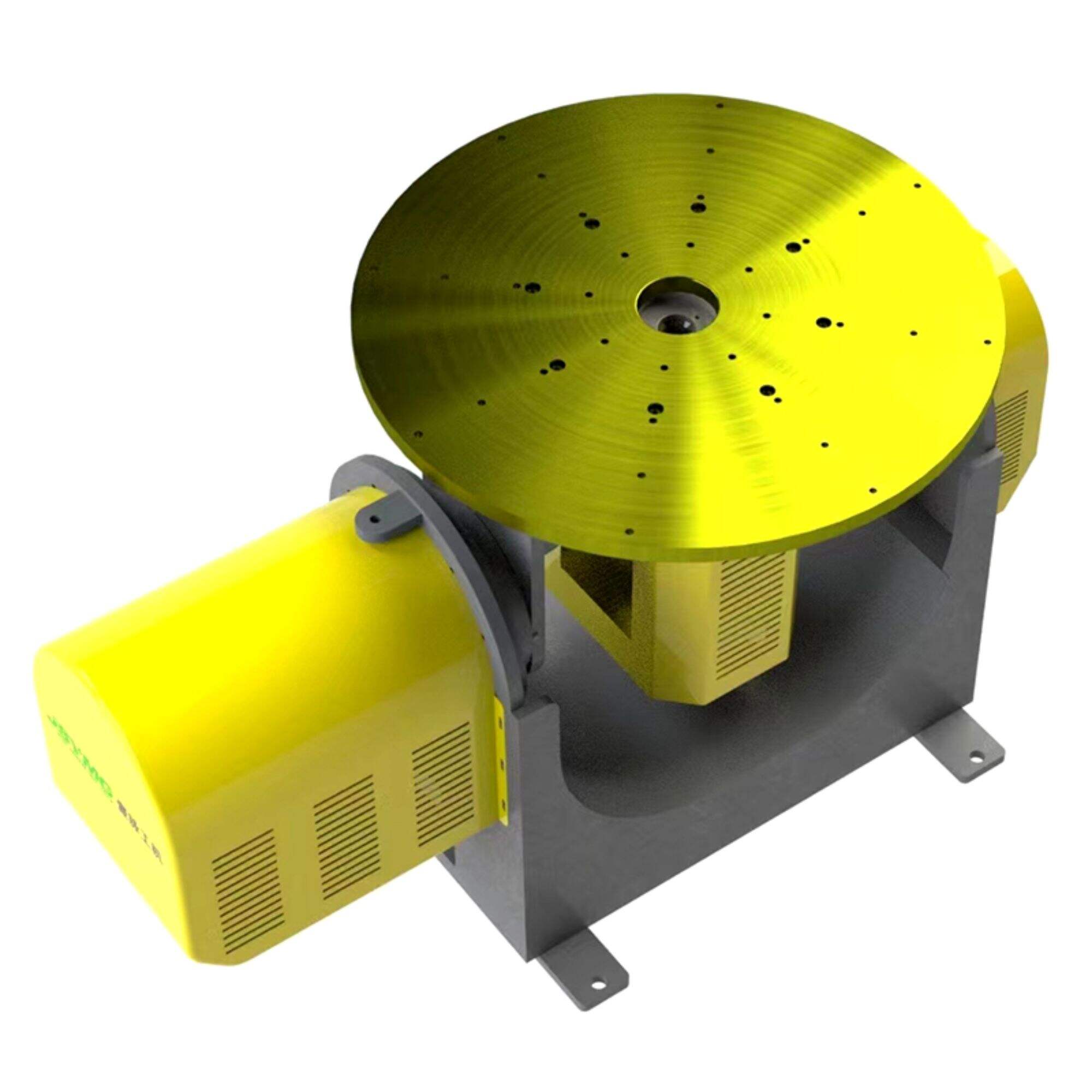

Single axis circular horizontal positioner |

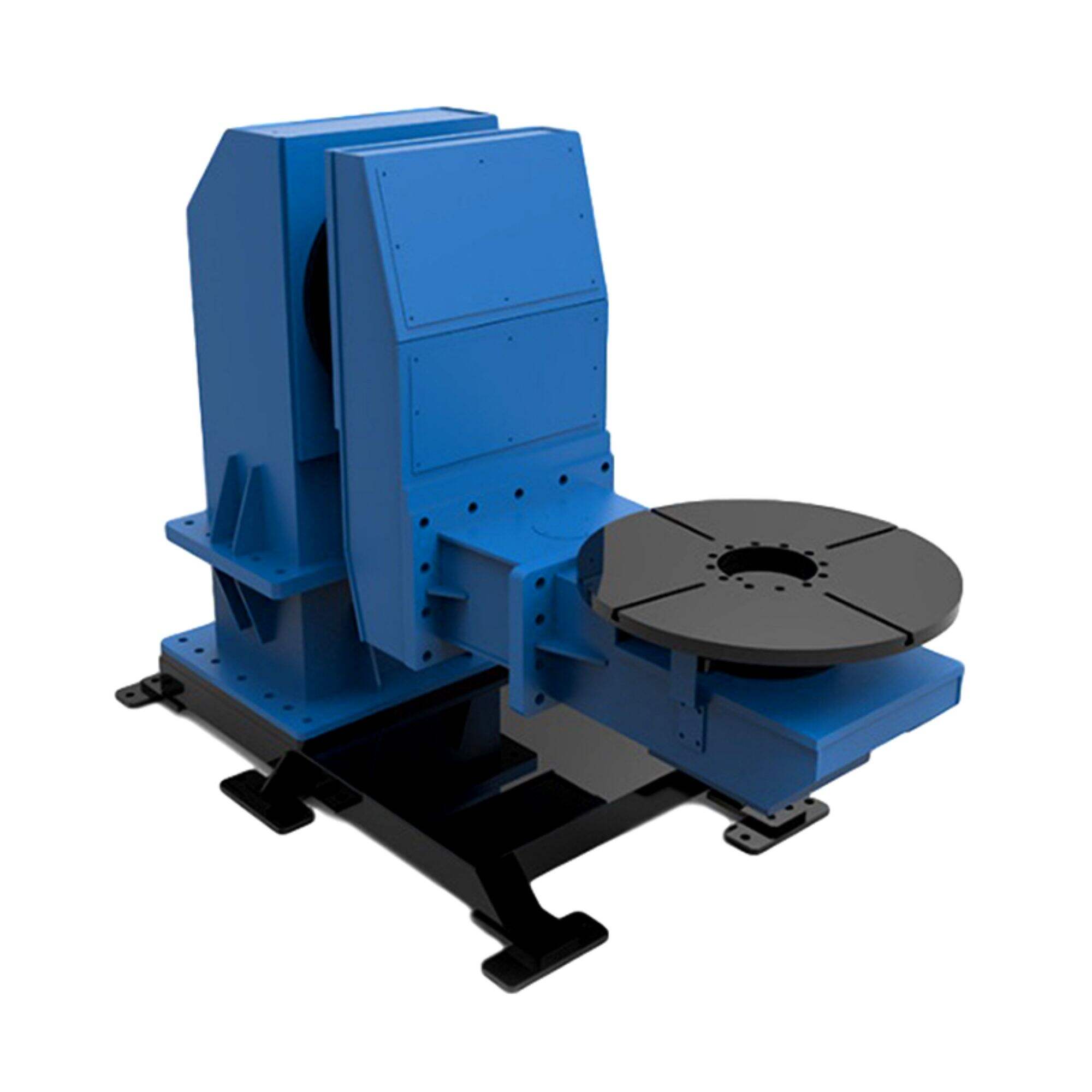

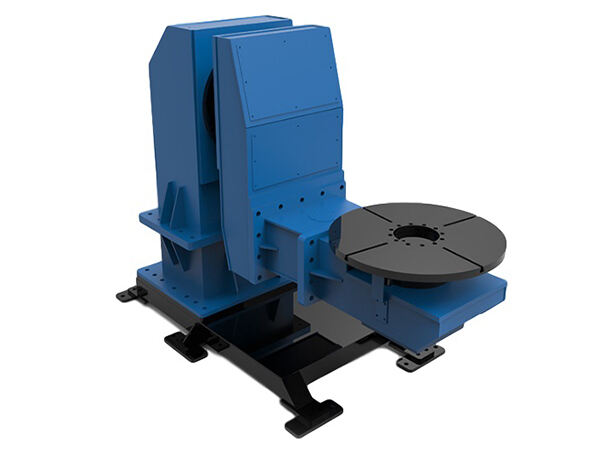

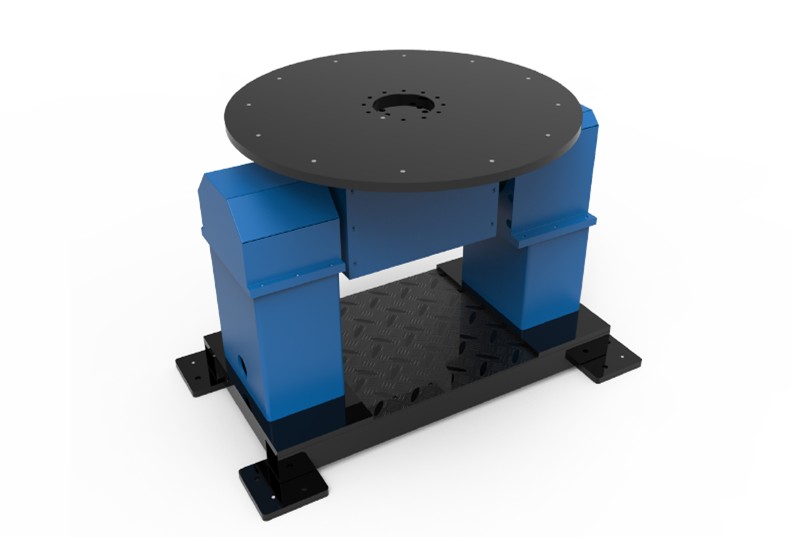

Double column and double axis positioner |

|

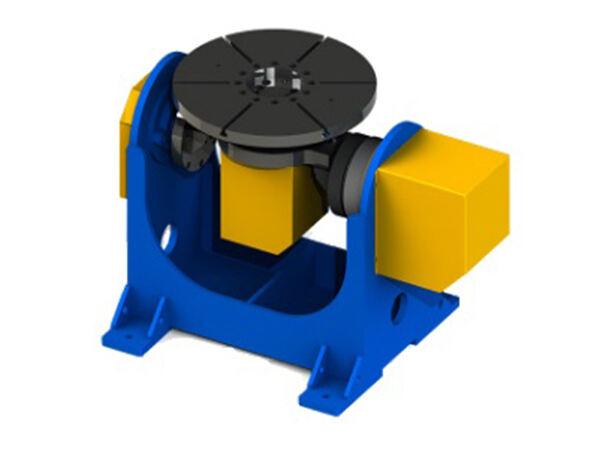

Double axis positioner |

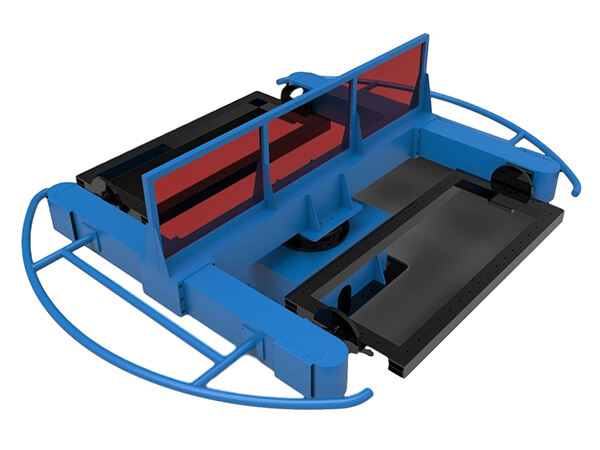

Three axis positioner |

| Installation |

|

After selecting the installation area of the positioner, please install it according to the following points: |

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR