DMK 200W Pulse Laser Cleaning Machine

| Product Description |

| Specification |

| Model | DPL-200 | DPL-300 |

| Average laser power | 200w | 300w |

| Scan width | 10- 200mm | 10- 200mm |

| Corrosion(50um) | 12m2/h | 18m2/h |

| Pulse frequency | 10-50KHZ | 10-50KHZ |

| Pulse length | 90-130ns | 90-130ns |

| Maximum single pulse energy | 10MJ | 10MJ |

| Oil(50um) | 15m2/h | 18m2/h |

| Paint(50um) | 11m2/h | 14.6m2/h |

| Cooling | Air cooling | Air cooling |

| Rated voltage | 220V | 220V |

| Equipment weight | 32KG | 37KG |

| Dimension | 400*400*500mm | 900*600*700mm |

| Cable length | 5/10M | 5/10M |

| For More Details |

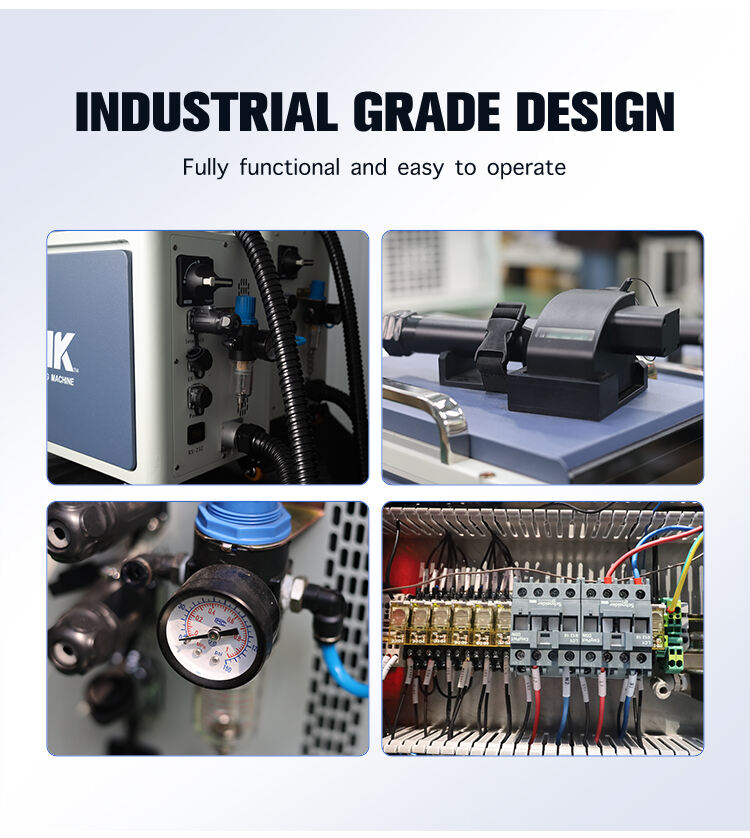

| Pulse series laser cleaning machine weighs 40kg, and the hand-held head weighs only 1.4kg. * it is light and convenient. The design of the portable box is convenient for users to use flexibly. * A variety of scanning graphics are set to ensure the cleaning effect under complex working conditions. * At the same time, it has ultra-high performance price ratio, no consumables, super energy saving, green environmental protection and no pollution. |

|

| Why Choose Us |

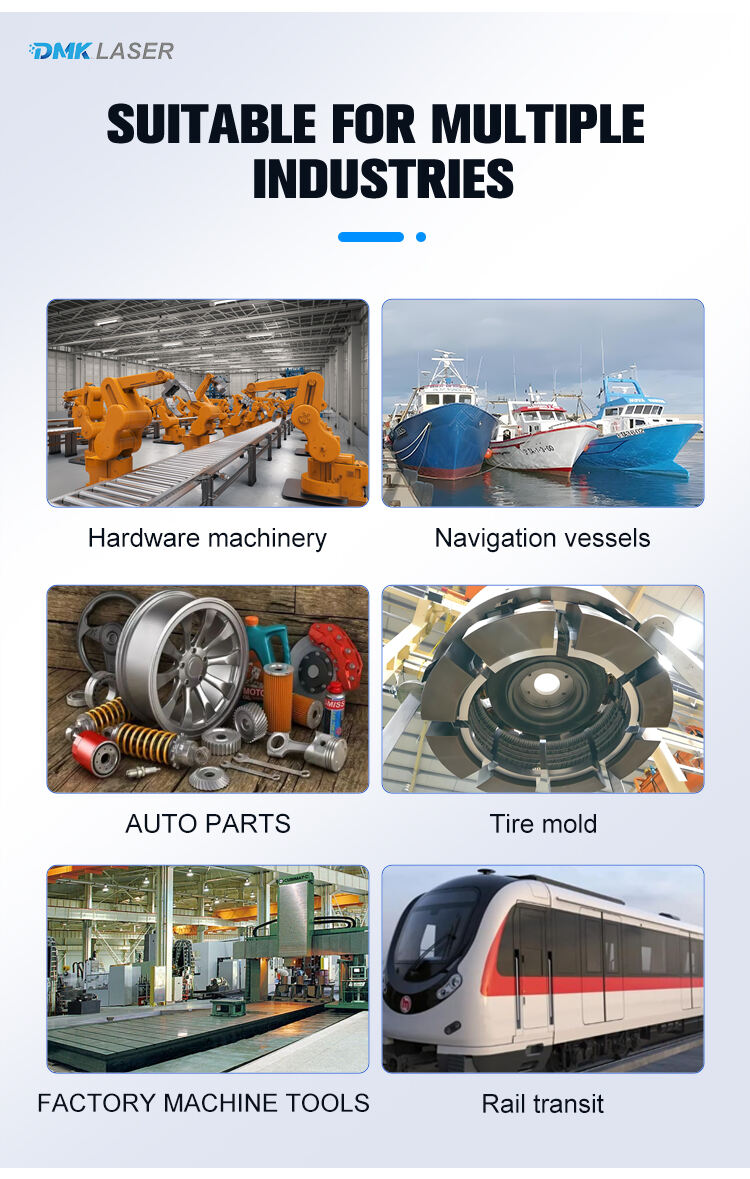

| Application |

| Company Profile |

Demark (Wuhan) Technology Co.,ltd has focused on laser technology for over 20 years in China, including laser cleaning, laser welding, laser marking and laser cutting applications. We started as a small operation, but now have become one of the leading suppliers in the laser industry in China.

FAQ

Q: Is a pulse fiber laser cleaning machine environmentally friendly?

A: Yes, pulse fiber laser cleaning machines are considered environmentally friendly because they do not use any chemicals or solvents that can harm the environment. Laser cleaning also produces minimal waste and reduces the need for disposable cleaning materials.

Q: Can a pulse fiber laser cleaning machine be used for cleaning food processing equipment?

A: Yes, pulse fiber laser cleaning machines can be used for cleaning food processing equipment, such as conveyors and stainless steel tanks. The non-contact nature of laser cleaning ensures that the equipment is cleaned thoroughly without the risk of contamination from cleaning agents.

Q: Can a pulse fiber laser cleaning machine be used for cleaning automotive parts?

A: Yes, pulse fiber laser cleaning machines can be used for cleaning automotive parts, such as engine blocks and transmission components. The laser energy can remove oil, grease, and other contaminants from the surface of the parts without damaging the underlying material.

Q: What are the advantages of using a pulse fiber laser cleaning machine over traditional cleaning methods?

A: The advantages of using a pulse fiber laser cleaning machine over traditional cleaning methods include:

- Non-contact cleaning, which eliminates the risk of damage to the surface being cleaned.

- High cleaning efficiency and effectiveness, which reduces cleaning time and costs.

- Minimal waste production and reduced environmental impact.

- No need for cleaning chemicals or solvents, which reduces health and safety risks.

- Versatility, as pulse fiber laser cleaning machines can be used to clean a wide range of materials and surfaces.

Q: How does a pulse fiber laser cleaning machine work?

A: A pulse fiber laser cleaning machine works by emitting a high-intensity laser beam that interacts with the surface being cleaned. The laser energy causes the contaminants on the surface to vaporize or sublimate, leaving the underlying material clean and undamaged. The cleaning process can be controlled by adjusting the laser power, spot size, and scanning speed to achieve the desired cleaning results.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR