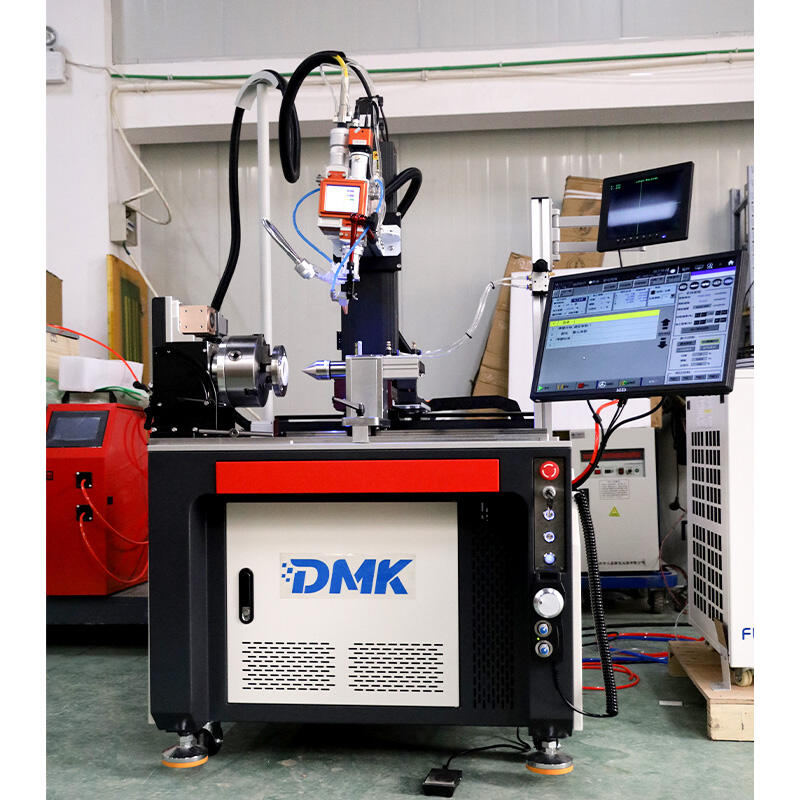

Desktop 4-6 Axis Automatic CW Fiber Laser Welding Machine

| Product Description |

|

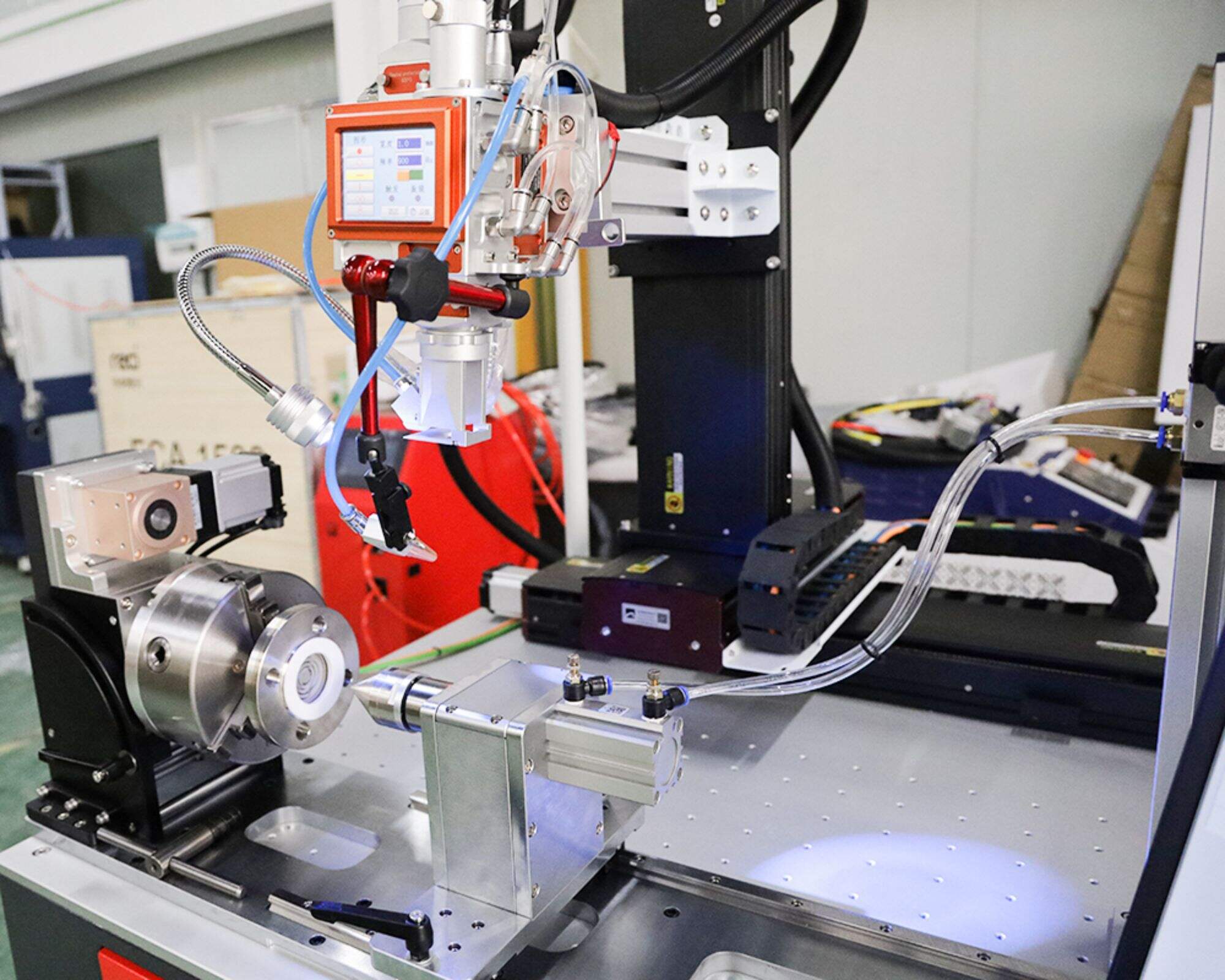

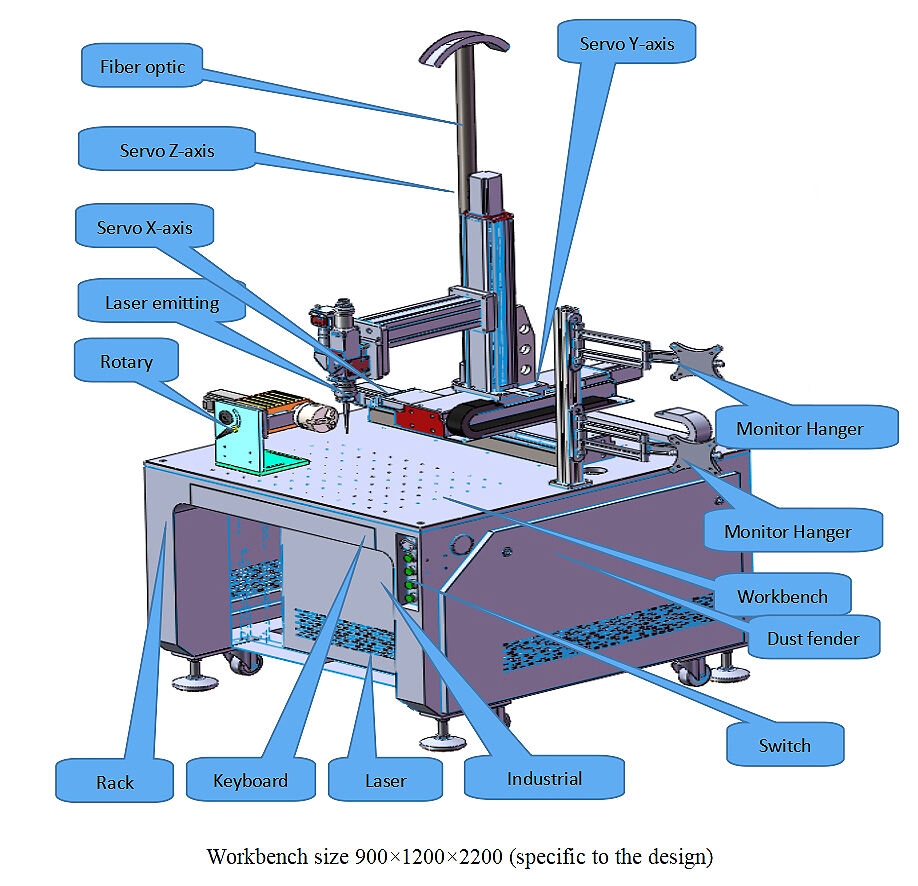

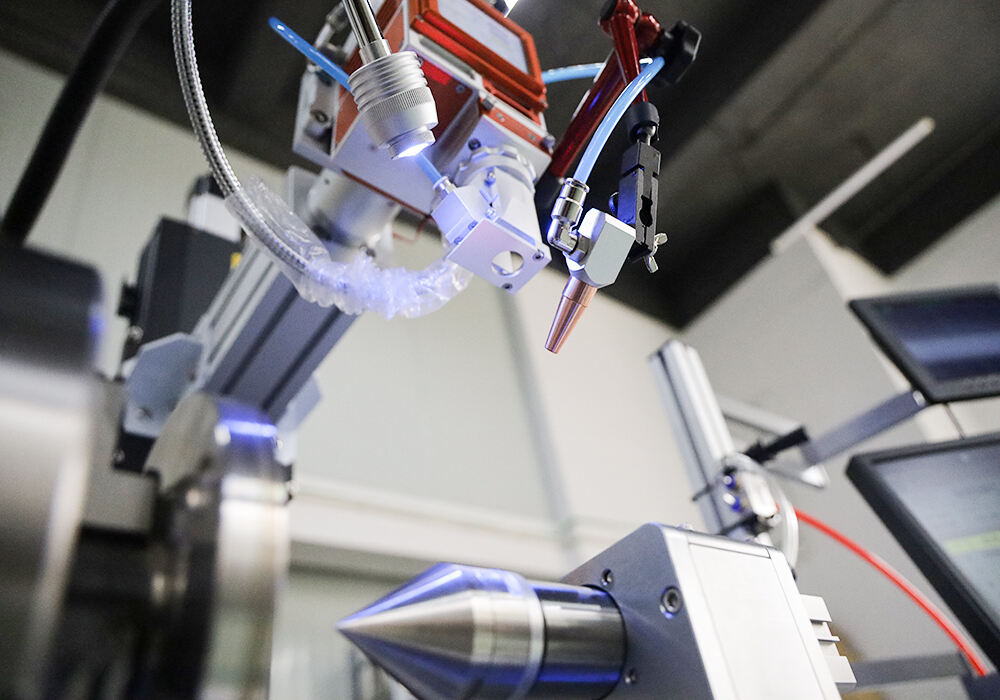

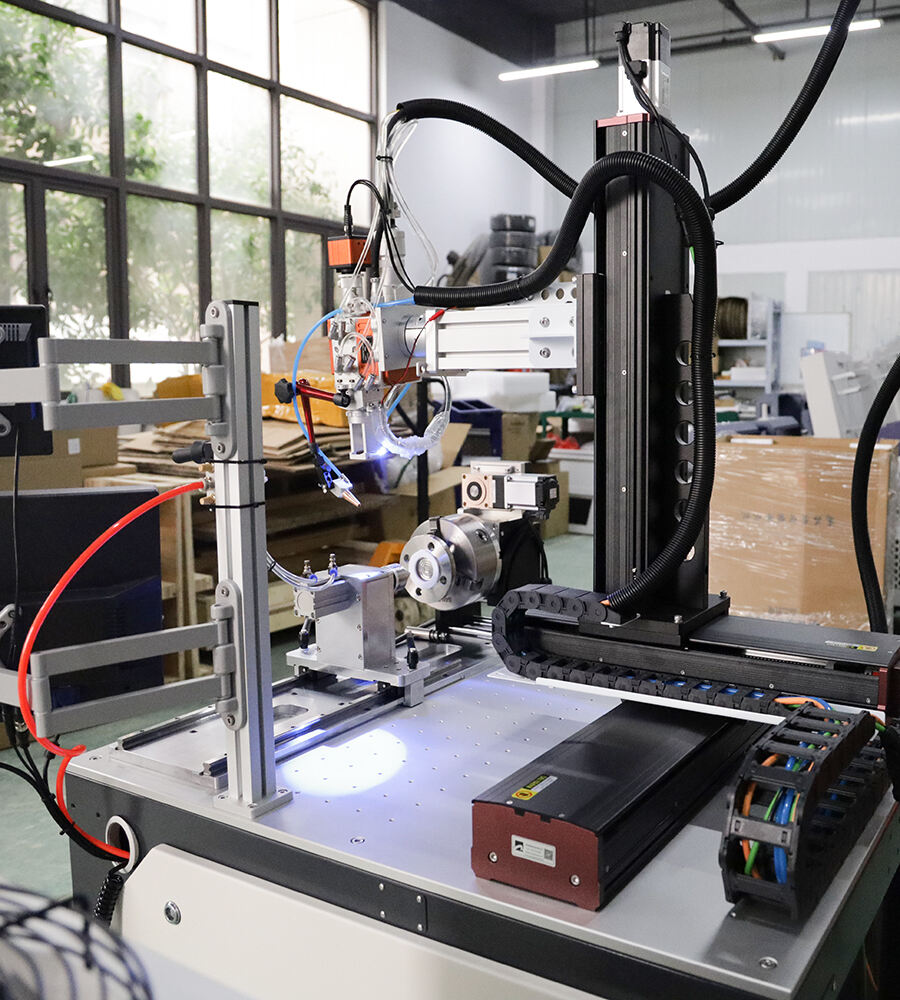

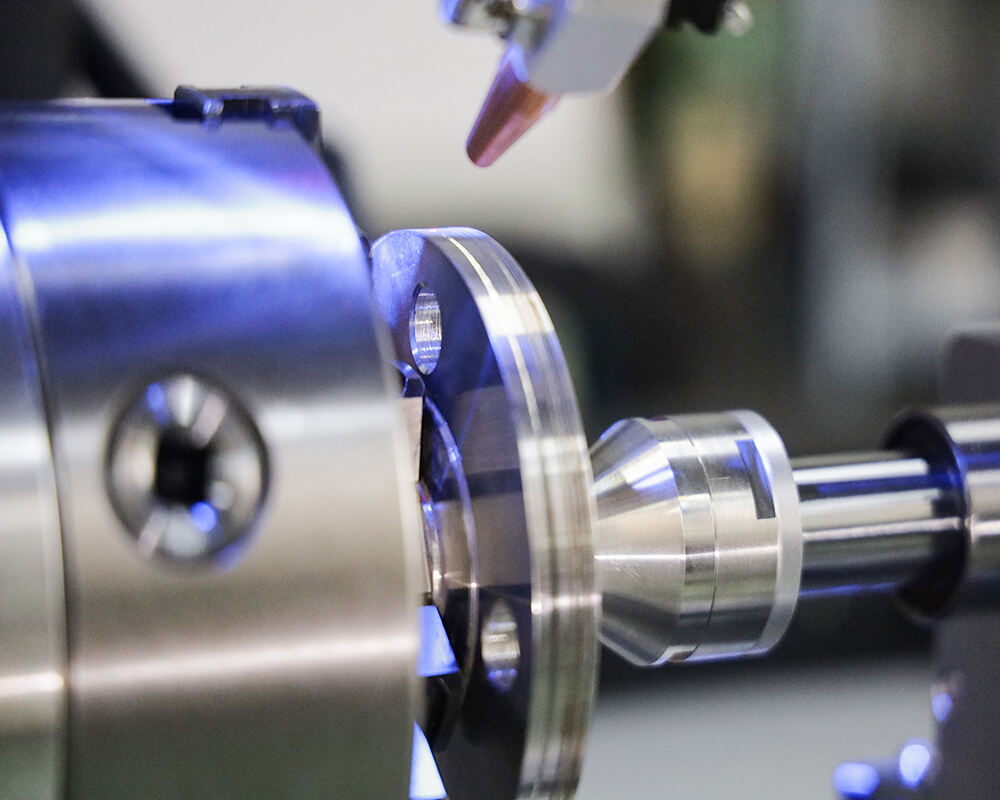

This equipment is designed for the customer automated laser welding needs, mainly including laser welding mainframe (fiber laser + fiber double pendulum welding head + six-axis welding control system + special welding software), chiller, multi-axis welding table and servo rotary table, etc. The structure of the main table is as follows.

|

| For More Details |

|

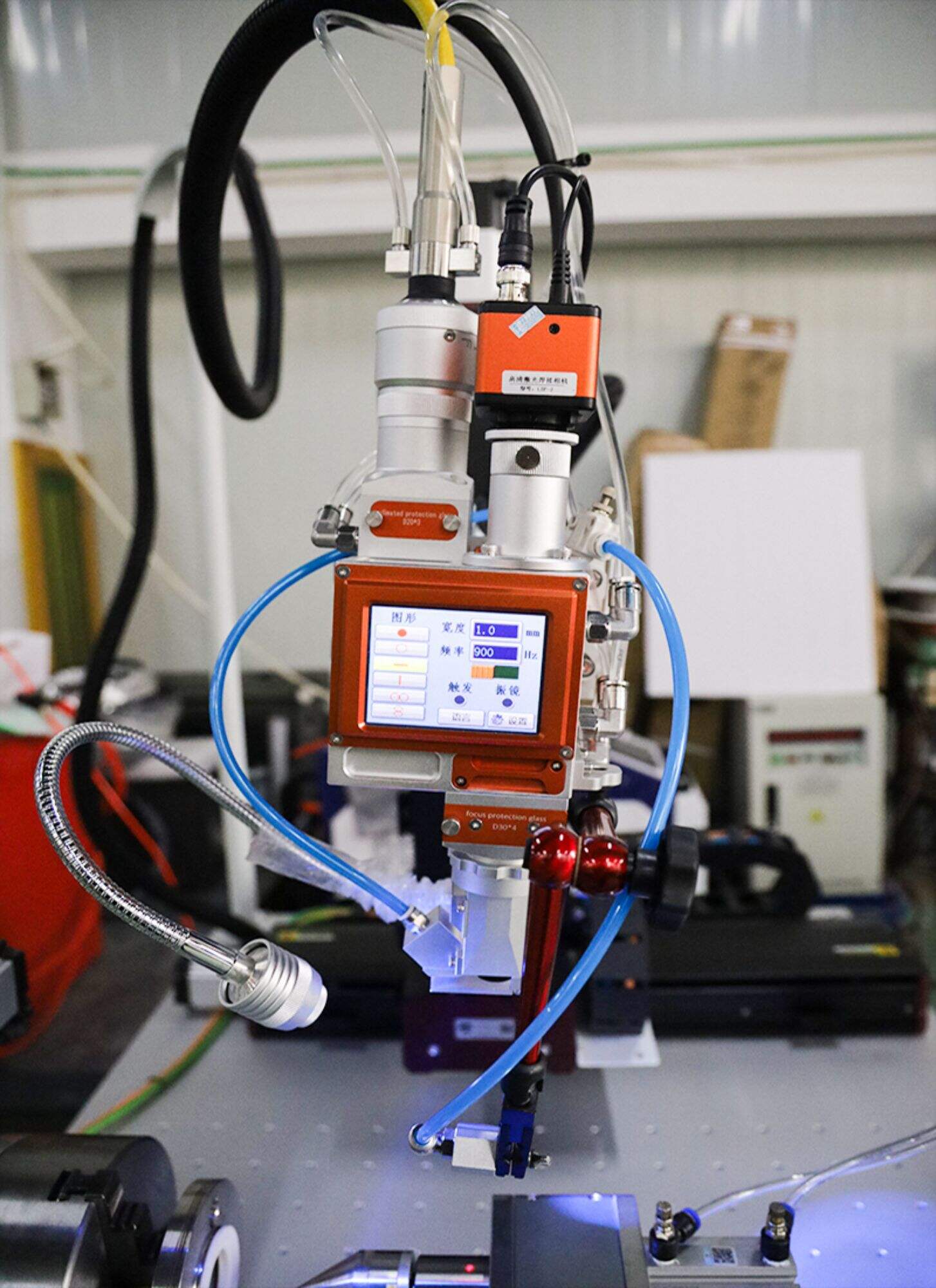

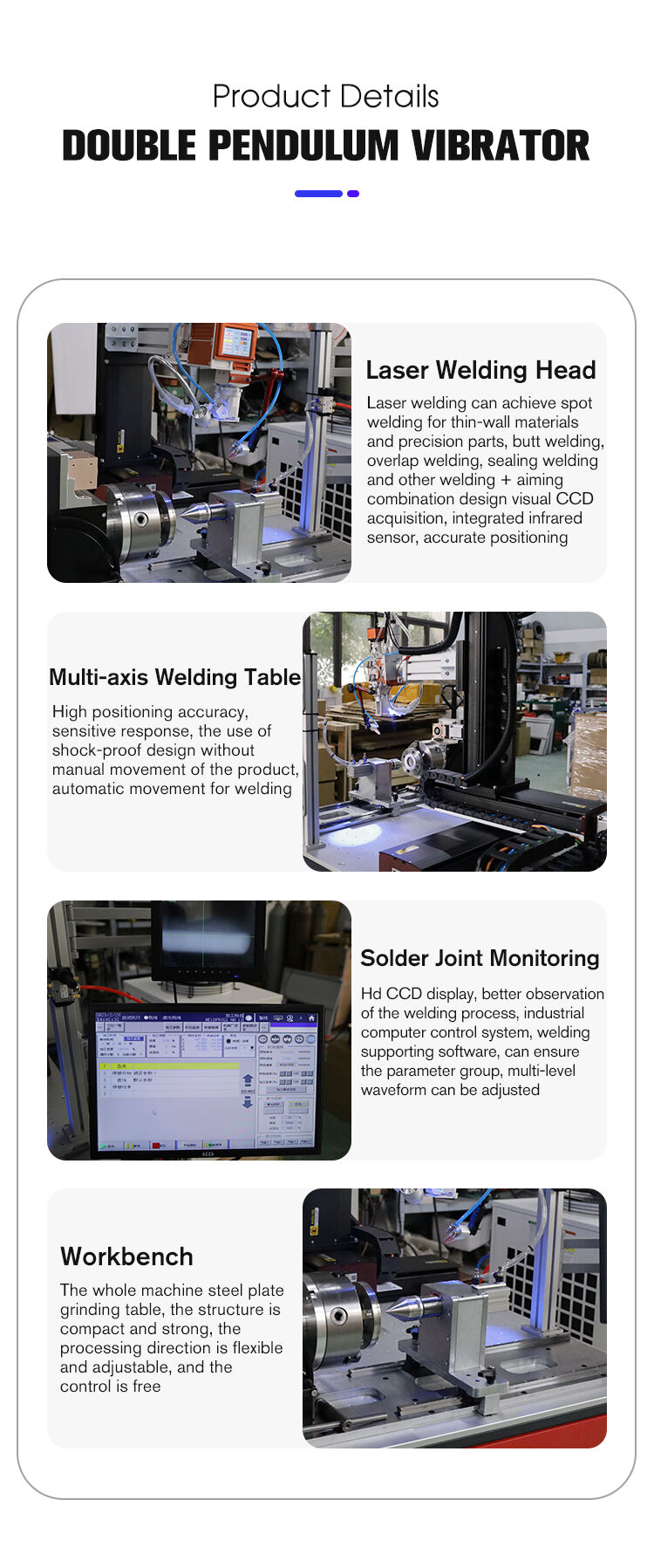

Adjustable light spot shaking welding head |

Fiber laser source for welding |

|

laser chiller |

X Y Axis Move Table |

|

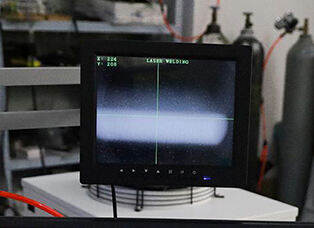

CCD Camera Display |

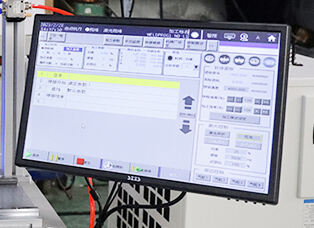

Special Welding Software |

| Parameter |

| Model | DHH-1000 | DHH-1500 | DHH-2000 | DHH-3000 |

| Laser power | 1000W | 1500W | 2000W | 3000W |

| Laser wavelength | 1070nm | 1070nm | 1070nm | 1070nm |

| Fiber length | 10/15m | 10/15m | 10/15m | 10/15m |

| Fiber core diameter | 20um/50um | 20um/50um | 20um/50um | 20um/50um |

| Stainless steel welding depth | 2mm | 3mm | 4mm | 5mm |

| Carbon steel welding depth | 1.5mm | 2.5mm | 3.5mm | 5mm |

| Aluminum alloy welding depth | 1mm | 1.5mm | 2mm | 3mm |

| Instruct | Red light/CCD | Red light/CCD | Red light/CCD | Red light/CCD |

| Cooling method | Water cooling | Water cooling | Water cooling | Water cooling |

| Electricity demand | AC220V/50HZ | AC220V/50HZ | AC380V/50HZ | AC380V/50HZ |

| Total power | 6KW | 8KW | 10KW | 14KW |

| Application |

|

Application Industries: Application Materials:

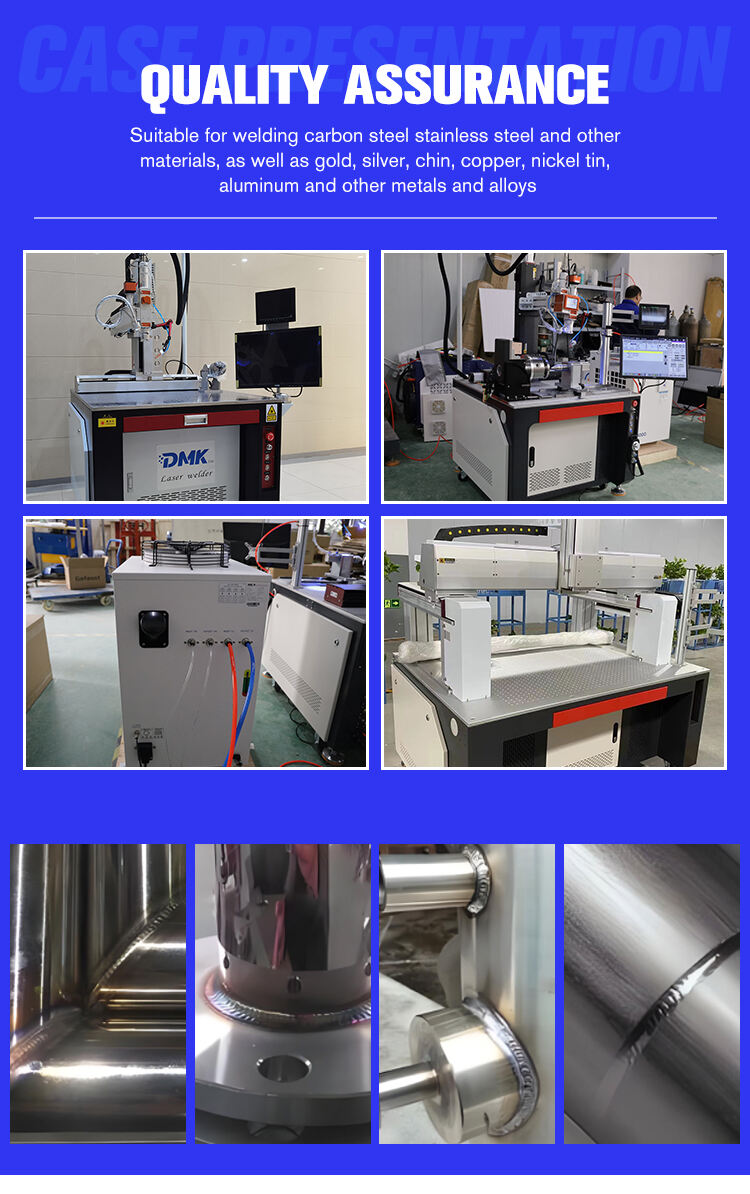

Stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys, it can also be used for a variety of welding between different materials.

|

||

|

| Company Profile |

|

Demark (Wuhan) Technology Co.,Ltd has focused on laser technology for over 20 years in China, including laser marking, laser welding, laser cleaning and laser cutting applications. We started as a small operation, but now have become one of the leading suppliers in the laser industry in China.

|

FAQ

Q: What is automatic fiber laser welding?

A: Automatic fiber laser welding is a type of welding process that uses a fiber laser to join two or more pieces of metal together. This process is automatic, meaning that it does not require the direct involvement of an operator.

Q: How does automatic fiber laser welding work?

A: In automatic fiber laser welding, the fiber laser beam is directed at the joint between the two pieces of metal. The laser beam melts the metal, and as it cools and solidifies, it forms a solid bond between the two pieces.

Q: What are the benefits of automatic fiber laser welding?

A: There are several benefits to using automatic fiber laser welding. This process is very precise, which means that it produces high-quality welds with minimal distortion. Additionally, automatic fiber laser welding is very fast, which can increase productivity and reduce production time.

Q: What types of materials can be welded using automatic fiber laser welding?

A: Automatic fiber laser welding is commonly used for welding metals such as stainless steel, aluminum, and titanium.

Q: What industries commonly use automatic fiber laser welding?

A: Automatic fiber laser welding is commonly used in the aerospace, automotive, and medical industries, as well as in the production of consumer electronics.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR