DMK Platform Pipe Cutting Machine

Product Description

Platform Pipe Cutting Machine | Efficient and Precise Automated Cutting Equipment

This platform pipe cutting machine is specially designed to meet customers' needs for automated laser pipe cutting. The equipment features a modular design, integrating high-performance laser cutting technology with an intelligent control system, ensuring efficient, stable, and precise cutting results.

Composition of the Automated Cutting Equipment

The equipment primarily consists of the following components:

- Laser Cutting Main Unit: Fiber laser, cutting head, multi-axis cutting control system, and dedicated cutting software.

- Chiller: Provides efficient cooling for the laser and cutting head, ensuring stable long-term operation of the equipment.

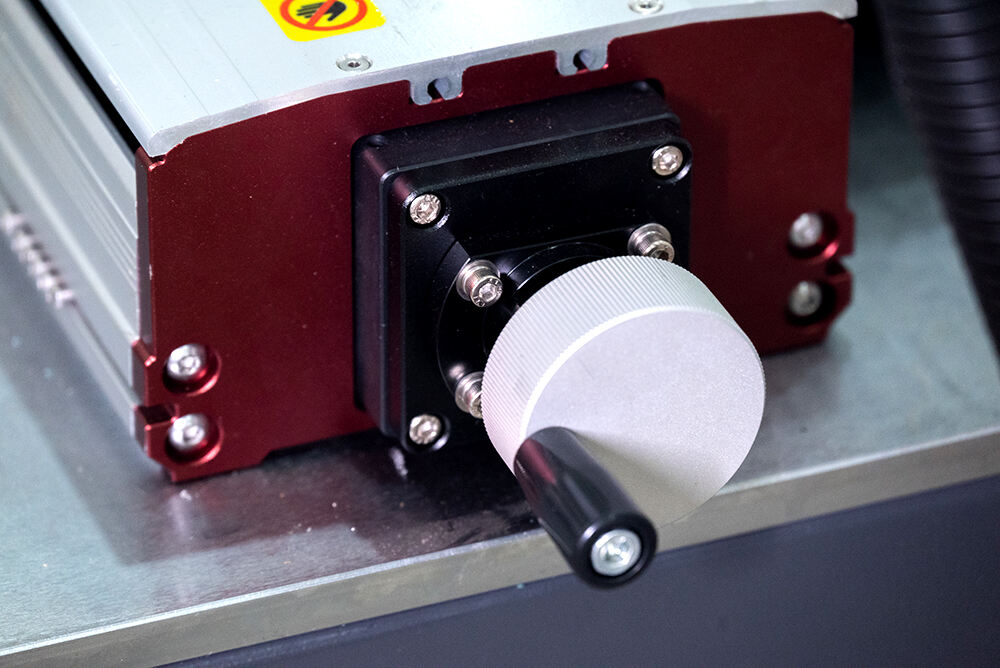

- Multi-Axis Cutting Worktable: Flexibly meets the cutting needs of pipes of various shapes and sizes.

- Servo Rotary Table: Precisely controls the rotation of the pipe, enhancing the processing accuracy of complex workpieces.

Key Component Performance Parameters

Laser Generator

-

Utilizes a high-efficiency fiber laser, paired with a dedicated water chiller, featuring the following characteristics:

- High photoelectric conversion efficiency, energy-saving and environmentally friendly.

- Superior beam mode for precise cutting.

- Fiber transmission supports long-distance processing.

- Compact size for easy transport.

- Modular design of laser power, supporting flexible upgrades.

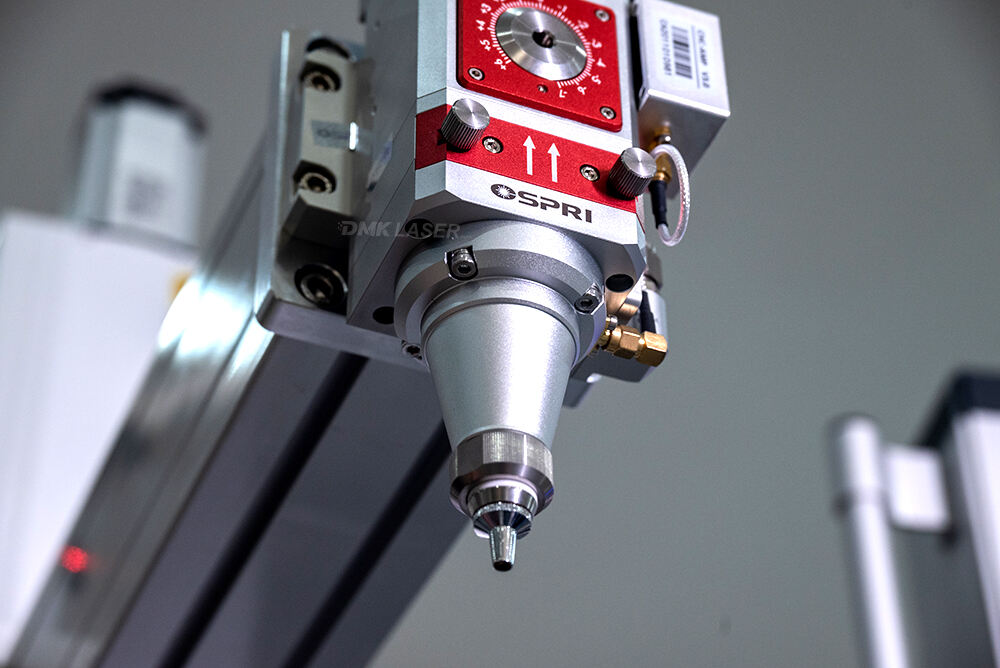

Cutting Head

- Compatible with standard QBH interfaces, offering strong compatibility.

- Supports focusing and adjusting functions to meet various cutting needs.

- Equipped with a three-piece protective mirror design, ensuring dust protection and prolonging equipment lifespan.

- Compact and lightweight, particularly suitable for cutting steel pipes.

CCD Monitoring System

- Equipped with a high-definition CCD camera and display.

- Magnification of monitoring ≥15 times, clearly displaying the cutting area and trajectory.

- Automatic red light indication for focusing, ensuring precise positioning of the cutting area.

- The laser spot focus coincides with the CCD focus, facilitating real-time monitoring.

- Coaxial CCD monitoring assists in determining the optimal cutting path.

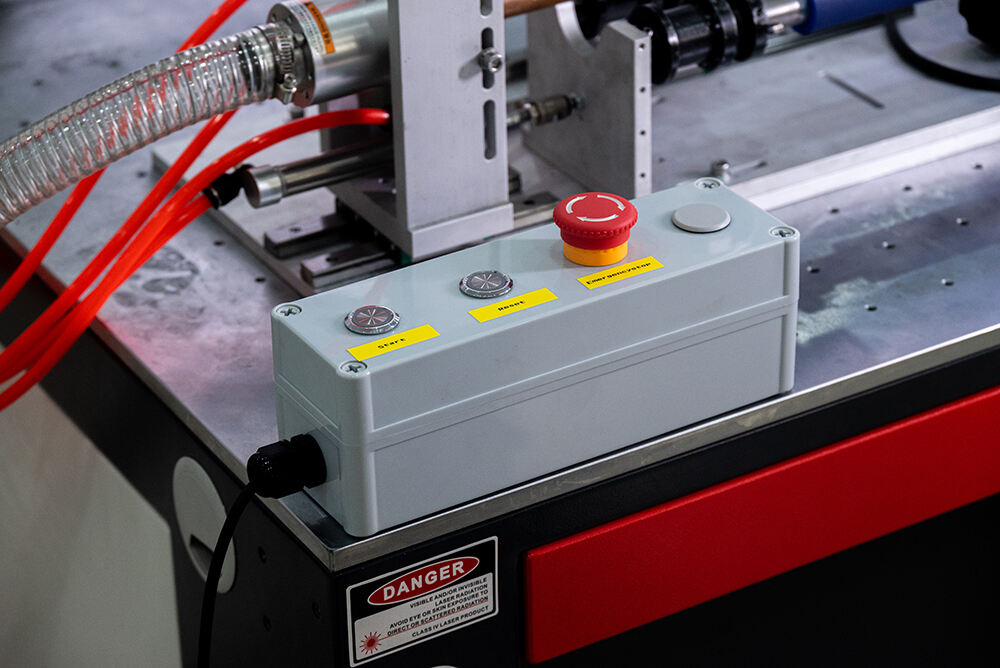

Control System

-

Utilizes an intelligent laser cutting control system with the following functions:

- CAD/CAM processing trajectory import, supporting complex graphic cutting.

- Real-time monitoring of the cutting process to ensure cutting accuracy.

- Supports 4 to 6-axis motion control, providing multifunctional digital interfaces.

- Integrated system design simplifies the operating process and improves production efficiency.

|

|

|

|

|

|

|

|

Applicable Scenarios

The platform pipe cutting machine is widely used in pipe processing, automotive manufacturing, metal piping, and other fields, particularly suitable for industrial production environments with high precision and efficiency requirements.

Equipment maintenance

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR