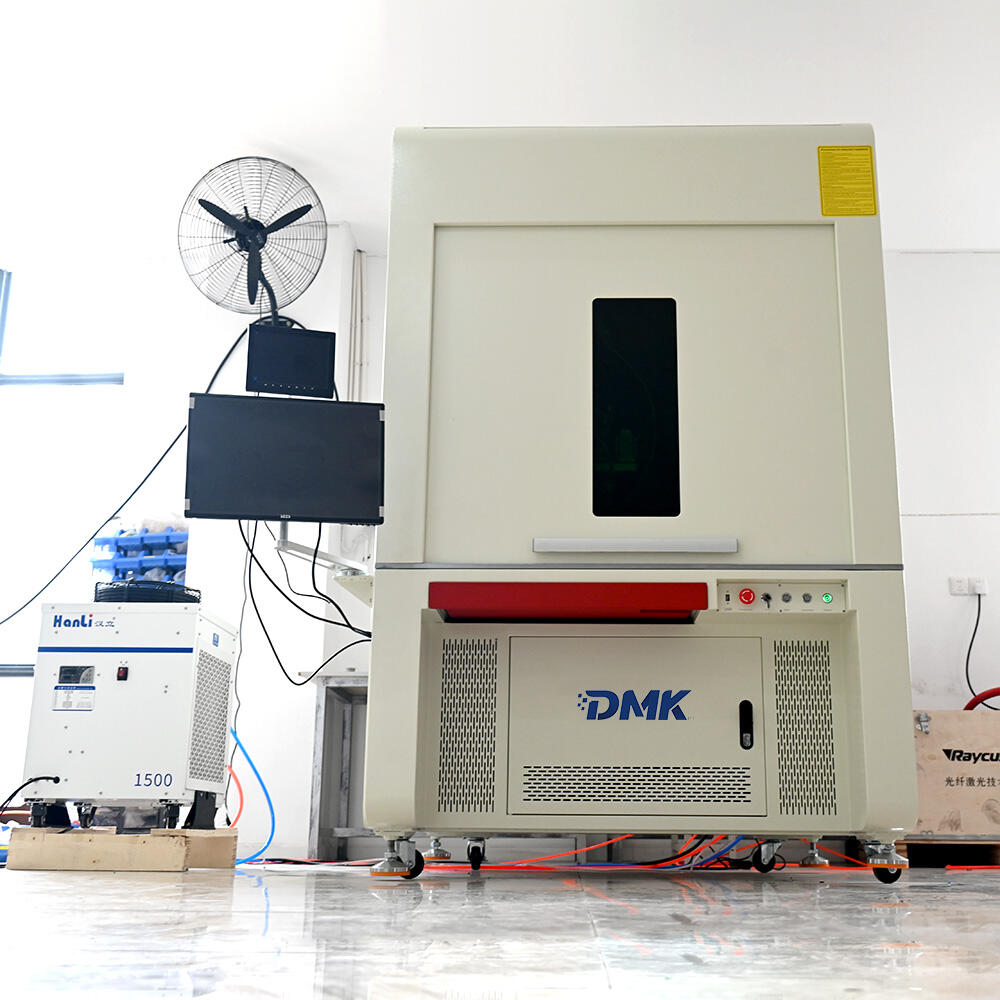

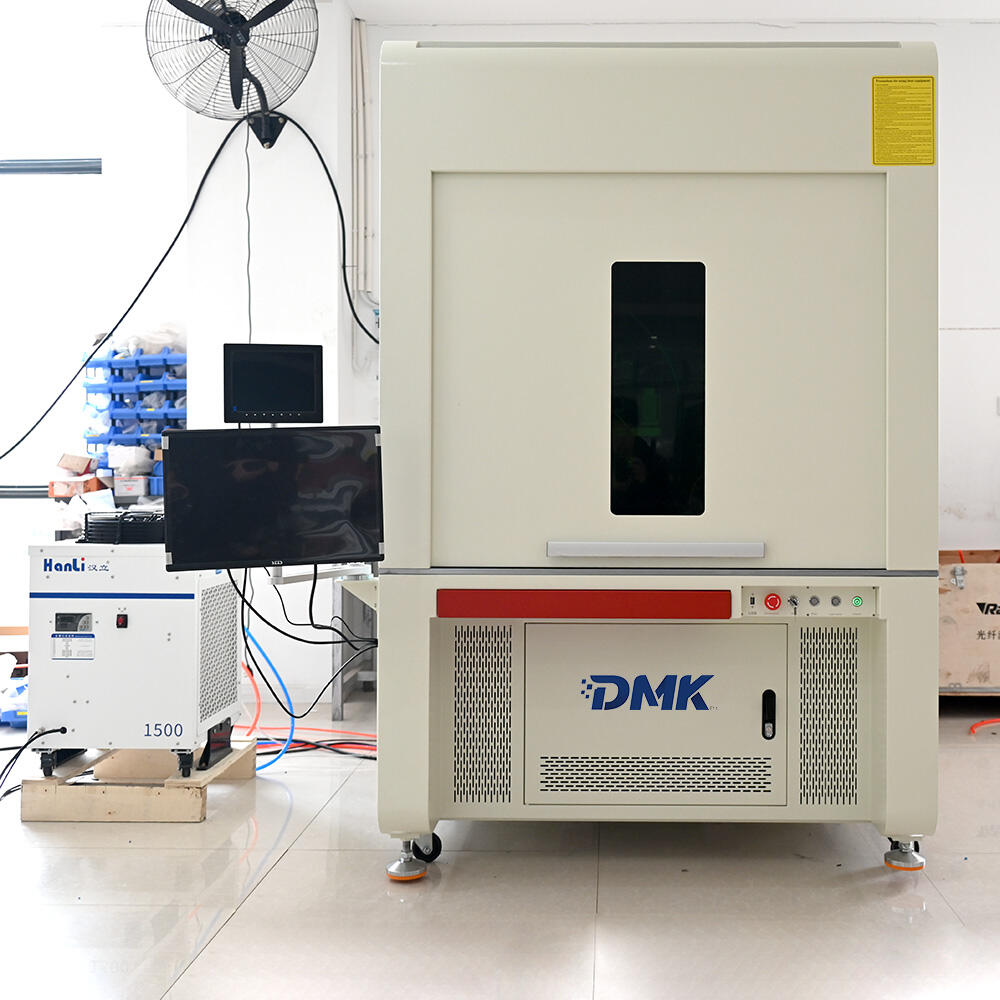

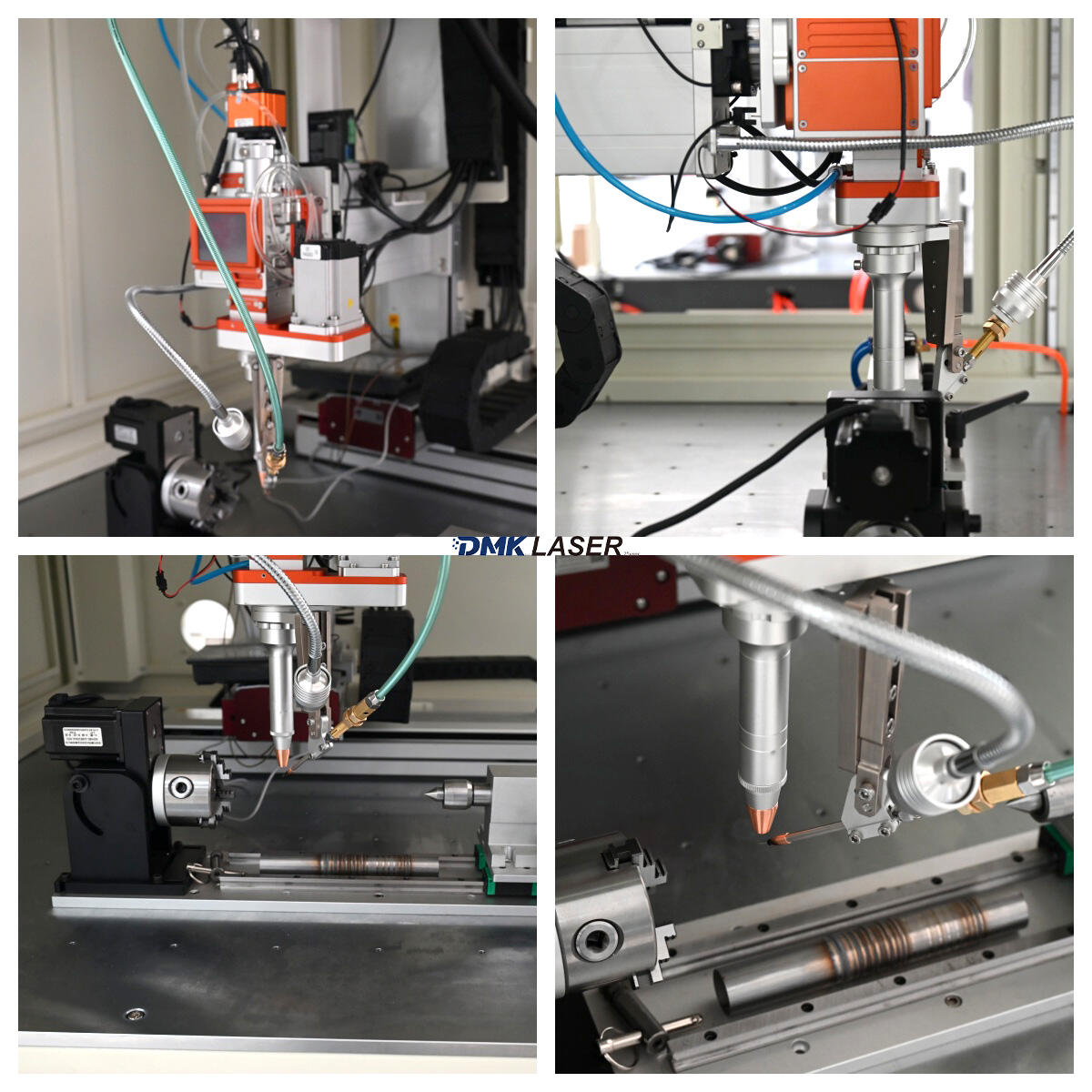

DMK Laser Enclosed Platform Automotive Welding Machine

Product Description

The Enclosed Platform Welding Machine is an advanced laser welding solution equipped with a fully enclosed protective cover, providing enhanced safety, environmental protection, and user-friendly operation. This machine offers high precision and flexibility for a wide range of welding tasks, making it ideal for both small batch production and large-scale manufacturing. With customizable worktables, laser power options, and automation configurations, the machine can be tailored to meet specific production needs.

Features

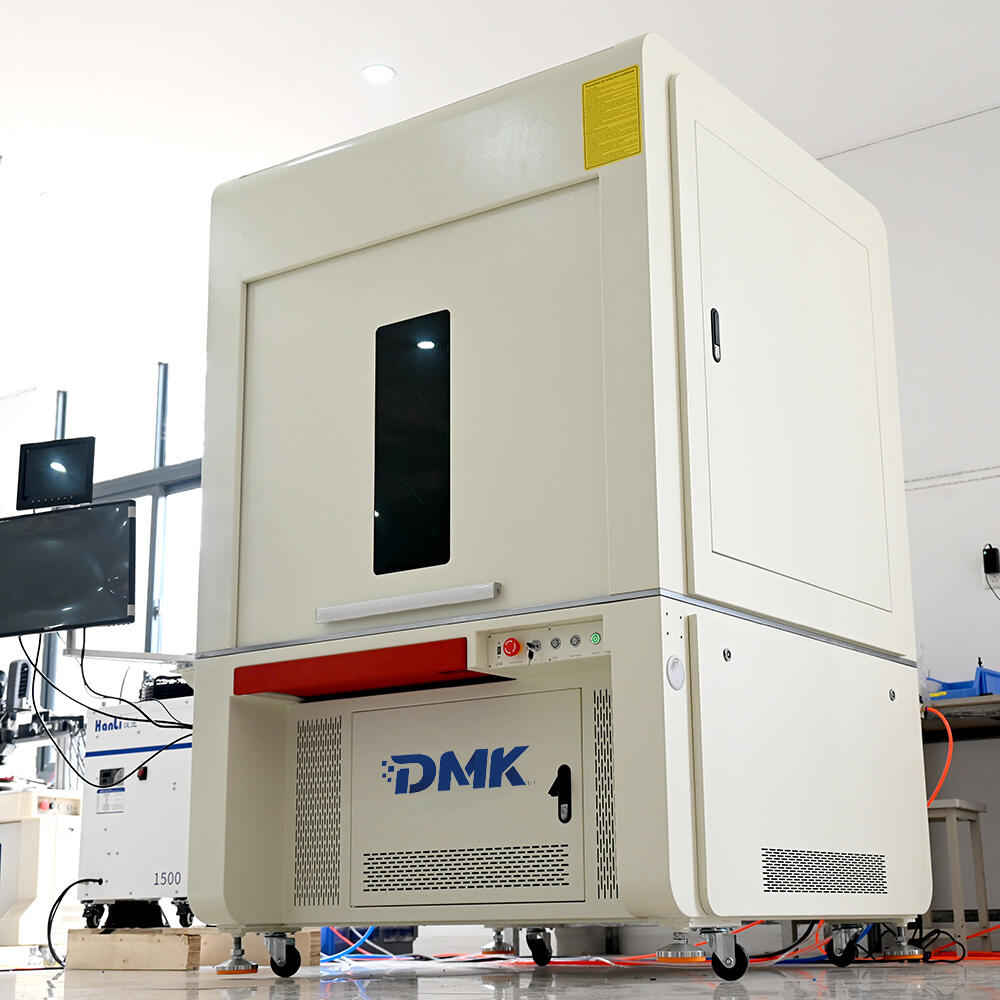

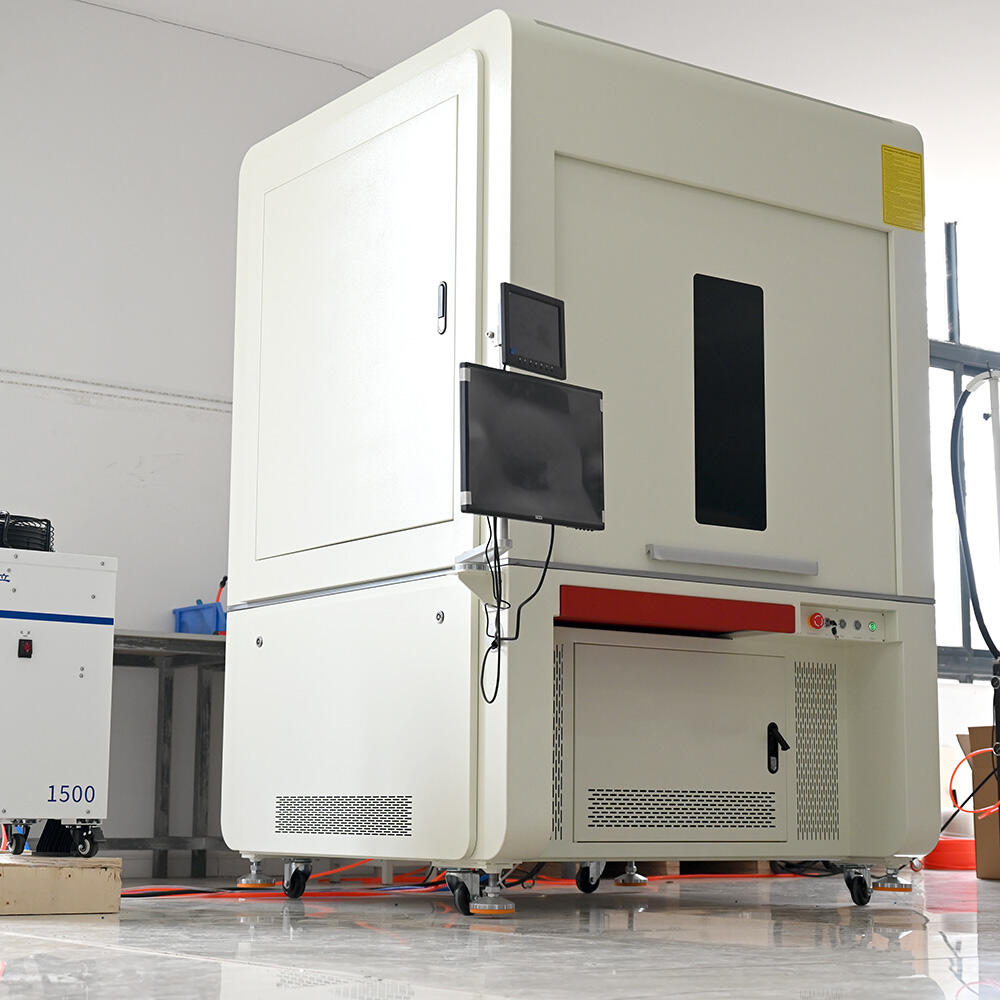

- Enclosed Design for Safety: Fully enclosed housing with observation window protects operators from laser radiation and welding fumes.

- Customizable Work Area: Platform size, laser power, and fixture options can be customized to fit your production requirements.

- High Precision Welding: Equipped with advanced laser control and high-accuracy motion system to ensure consistent weld quality.

- User-Friendly Interface: Intuitive touchscreen operation with real-time monitoring for ease of use.

- Integrated Exhaust System: Optional fume extraction system ensures a clean and safe working environment.

- Flexible Automation Options: Supports integration with automatic loading/unloading systems for increased efficiency.

|

|

Technical Parameters

| Laser Type | Fiber Laser / YAG Laser (customizable) |

| Laser Power | 500W / 1000W / 1500W / 2000W (customizable) |

| Worktable Size | Customizable (Typical: 600mm x 600mm, 800mm x 800mm, etc.) |

| Positioning Accuracy | ±0.02mm |

| Control System | CNC System with Real-time Monitoring |

| Observation Window | Laser Protective Glass (compliant with international standards) |

| Cooling Method | Water Cooling |

| Power Supply | AC 220V / 380V, 50/60Hz |

| Exhaust System | Optional Fume Extraction System |

Applications

- Precision welding of stainless steel, aluminum, carbon steel, copper, and other metals.

- Widely used in industries such as electronics, automotive, medical devices, hardware tools, and aerospace.

- Suitable for welding complex parts, enclosures, precision assemblies, and customized components.

Customization Options

- Laser power and type

- Worktable size and fixture design

- Automation level (manual loading, semi-automatic, fully automatic)

- Integration with conveyor systems or robotic arms

- Tailored software functions based on production needs

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR