DHH-1000 Fiber Optic Mold Laser Welding Machine

Product Description

Using fiber laser, it has high reflectivity, strong energy, maintenance-free, dimming-free, and low power consumption. Compared with traditional mold welding, it is small, safe, stable and has a long service life. 1000W fiber laser meets the welding and processing needs of molds and products with large amounts of copper and aluminum welding. The high load-bearing base and workbench maintain the advantages of lightness and flexibility while providing higher load-bearing capacity. Equipped with a 1.5P high-power integrated water chiller to ensure the stability of high-power welding.

Features

1. Using fiber laser, it has high reflectivity, strong energy, maintenance-free, dimming-free, and low power consumption. Compared with traditional mold welding, it is small, safe, stable and has a long service life.

2. The 1000W fiber laser can meet the welding processing needs of molds and products with large amounts of copper and aluminum welding. It can repair molds and weld products, and can also be equipped with a handheld welding head.

3. The high load-bearing base and workbench maintain the advantages of being light and flexible while providing higher load-bearing capacity.

4. Equipped with .1.5P high-power integrated water chiller to ensure the stability of high-power welding.

For More Details

| Parallel Light Path Microscope | |

|

Parallel light path high-definition microscope photos |

Binocular pupillary distance is adjustable and can be turned for observation |

| Accessories and Consumables | |

|

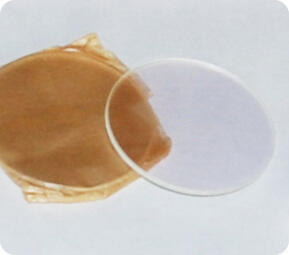

Mold laser welding machine protective lens Accessory description: During the use of the mold laser welder, molten iron often splashes onto the laser lens when melting. This lens plays a role in protecting the internal focusing lens. If too much molten iron adheres to the protective lens, the laser power will be affected. When the time comes, the lens needs to be replaced. |

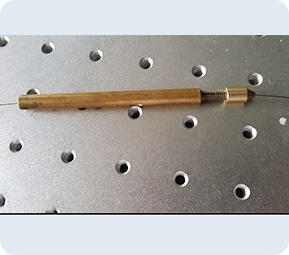

Mold laser welding machine wire pen Accessory description: This laser wire pen has a lock, which can lock the 0.3-0.6 welding wire. Especially for deep holes and deep grooves where it is difficult to hold the wire for repair welding, the wire pen plays a role in stabilizing the wire and is an ideal tool for laser repair of molds. An indispensable tool. |

|

Mold laser welding machine foot switch Accessory description: When using a laser welder, the laser control foot pedal will be continuously stepped on and released according to different situations. Long-term use will cause the foot switch to age or malfunction. If malfunction is found, consider replacing the foot switch. |

Imported mold laser welding wire Consumables description: This series of laser welding wire is imported from Germany and packaged in a sealed plastic tube. It is mainly used for laser repair welding of molds with higher requirements. It can meet the needs of laser welding of mirror molds, nitrided molds, high hardness molds and other molds. |

|

Mold laser welding wire Consumables description: This series of laser welding wires are made of imported mold welding wires and are made of different materials. They can meet the laser repair welding quality of most molds and are cost-effective. |

Mold laser welding machine light bulb Description of consumables: After the lighting bulb is used for a period of time, it will age or be damaged due to the life of the bulb and needs to be replaced in time. |

Application Scope

Repair of large precision injection molding and die-casting molds, repair of sand holes and air holes in beryllium copper molds, aluminum castings and copper castings. Welding and repair welding of large products.

|

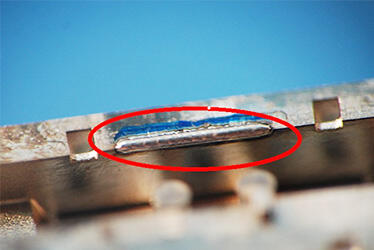

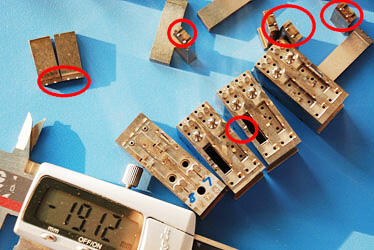

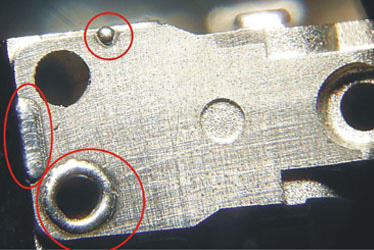

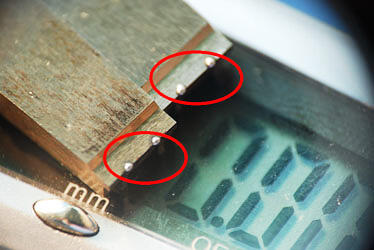

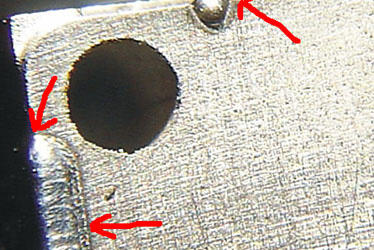

Precision plastic mold laser repair welding renderings |

Plastic mold laser welding renderings |

|

Plastic mold laser repair welding renderings |

Laser welding renderings of plastic mold precision parts |

|

Injection mold laser welding renderings |

Laser welding effect of injection mold precision parts |

Company Profile

Demark (Wuhan) Science & Technology Co.,Ltd Locates In Free Trade Zone Of East-Lake Hi-Tech Development District In Wuhan City, The Company Is Invested By High Level Technical And Managerial Professionals In China Laser Industry, With More Than 20 Years Working Experience In China Laser Cutting Industry, From The Intergration Of Laser Cutting Machine To The Operation Details Of Fabrication Factories, They Have Experienced The Time Changes And More Than Ten Thousand Installations All Over China, The Target Of Demark Is Exporting The Best Value Chain Of Chinese Laser Cutting Machine Or Fabricating Machineries To The Global Fabricators, To Be Your Best Partner When You Are Purchasing Laser Cutting Machine Or Fabricating Machineries In China With The Most Professional Service.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR