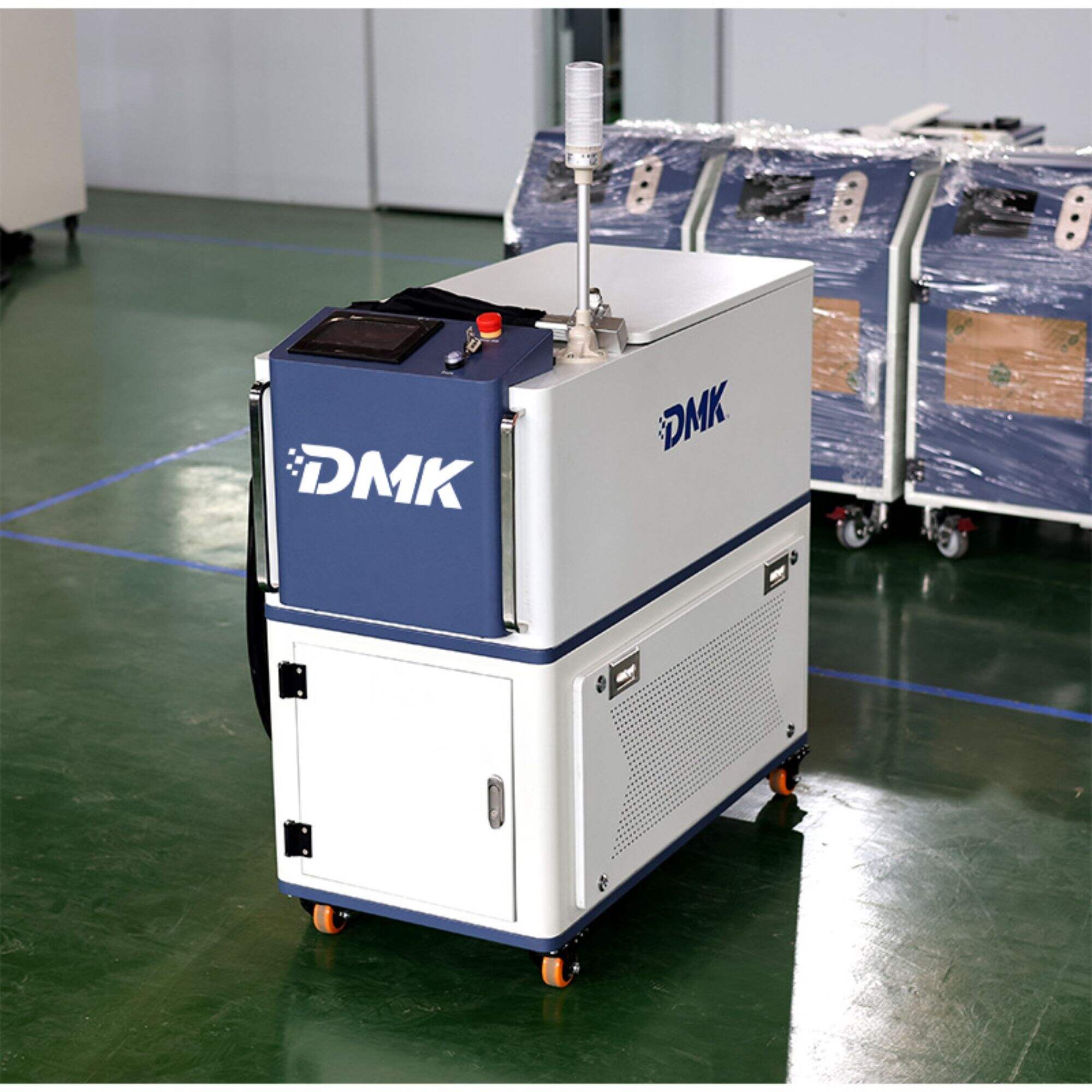

DMK Handheld 3000W CW Laser Texturing Cleaning Machine

Product Description

Laser cleaning machine is a new generation of industrial surface cleaning laser system. It adopts advanced laser light source, laser optical scanner and control system, and has laser etching, laser texturing function to meet the requirements of metal surface cleaning process.

DMK Laser cleaning machine can be used car perimeter, rubber mold, heritage restoration, ship, environmental protection industry, others, rail transit, high-end machine tools Remove coating, degumming, lithographic surface treatment, oil removal, pretreatment, paint removal, rust removal,etc.

Product Paramenters

| Type | DCL-2000 | DCL-3000 |

| Laser source | CW Fiber | CW Fiber |

| Laser Power | 2000W | 3000W |

| Fiber cable | 10-20 M | 10-20 M |

| Wavelength | 1070nm | 1070nm |

| Clean speed | ≤50M²/Hour | ≤80M²/Hour |

| Beam width | 10-300mm | 10-300mm |

| Scann speed | 0-7000mm/s | 0-7000mm/s |

| Cooling | Water cooling | Water cooling |

| Voltage | Single Phase 220, 50/60HZ | Three Phase 380, 50/60HZ |

| Weight | 220kg | 240kg |

Application

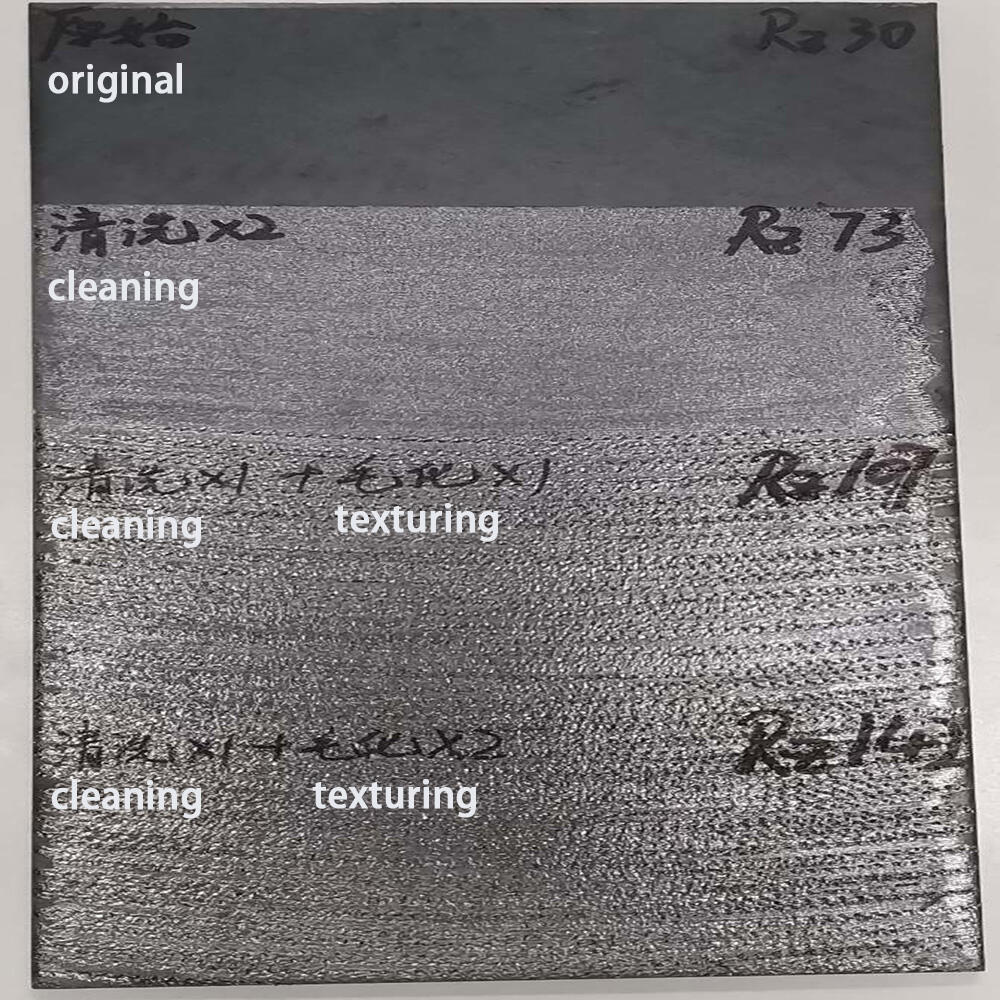

Texture effect

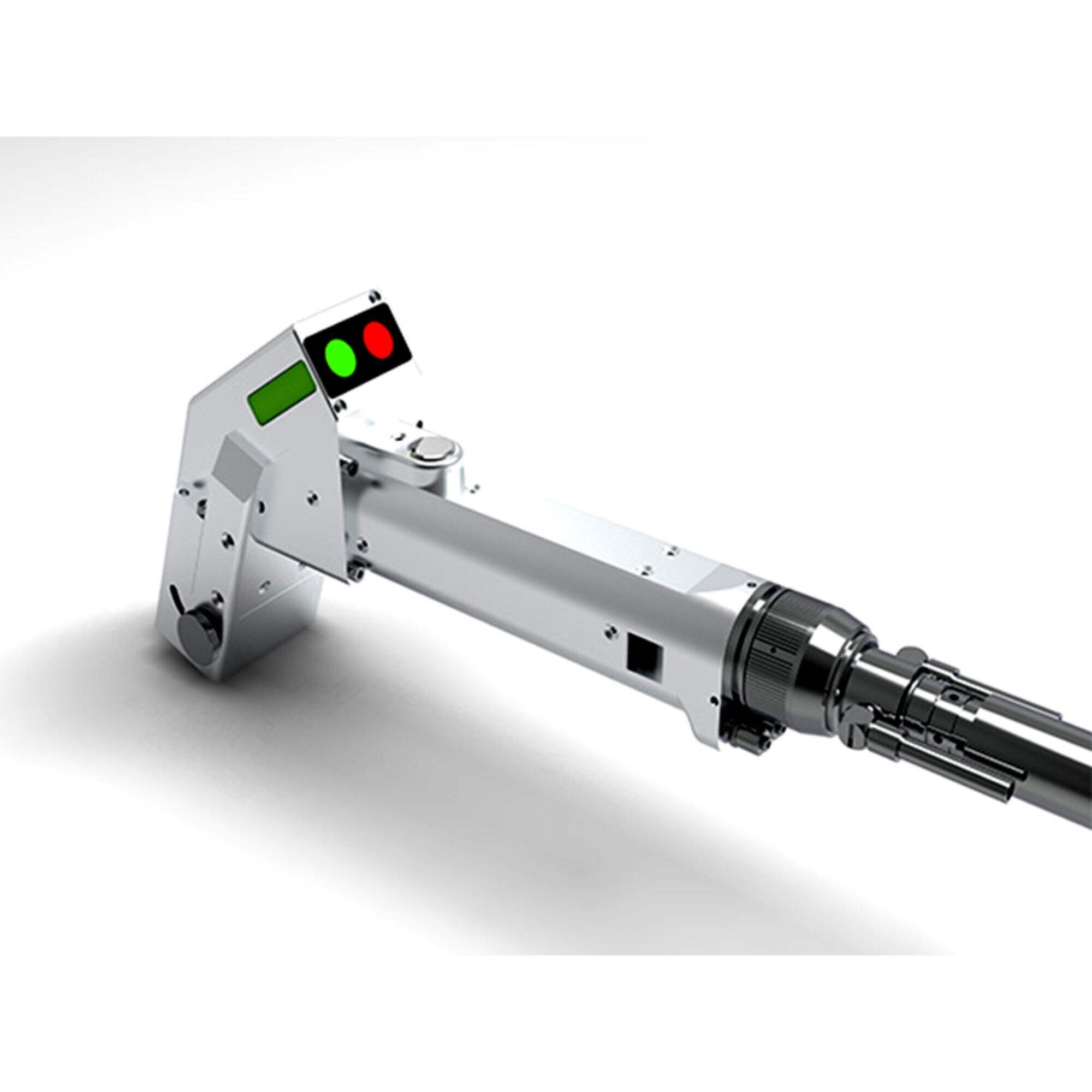

Use CW-H-3000W, connect the self-developed cleaning head, clean the carbon steel with oxide layer 2 times, clean 1 time + texturing 1 time, clean 1 time + texturing 2 times, and measure the roughness, as shown in the figure 1 shown. The results show that the degree of texturing effect is more obvious.

Figure 1

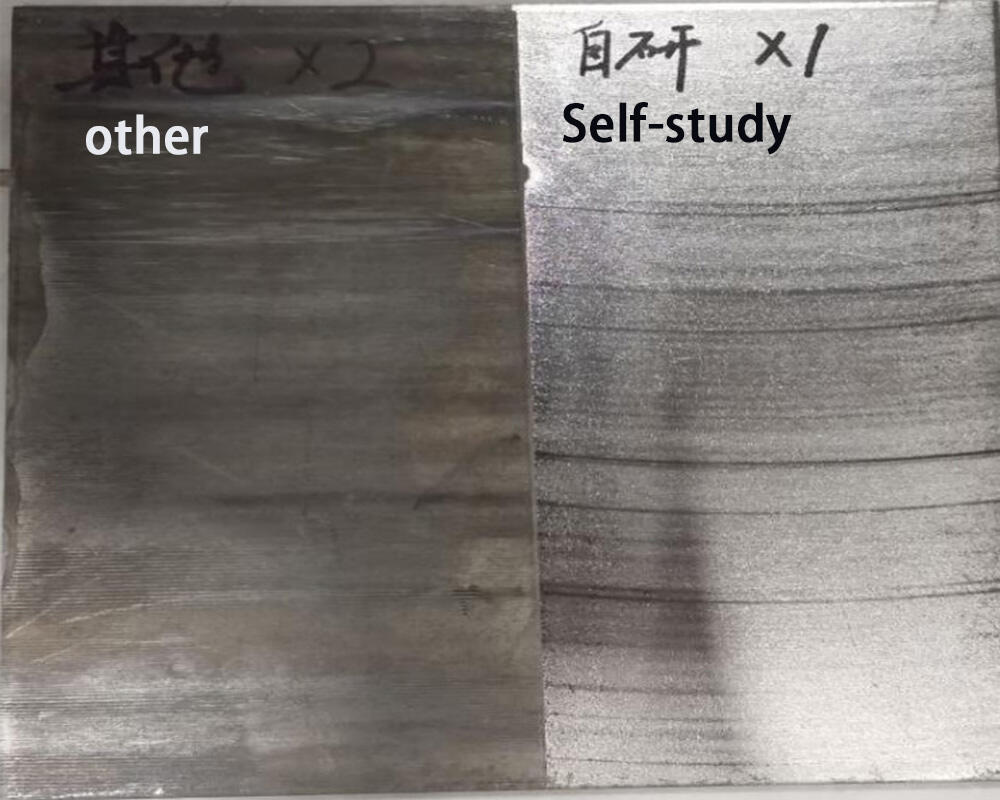

Carbon steel plate oxide layer cleaning effect

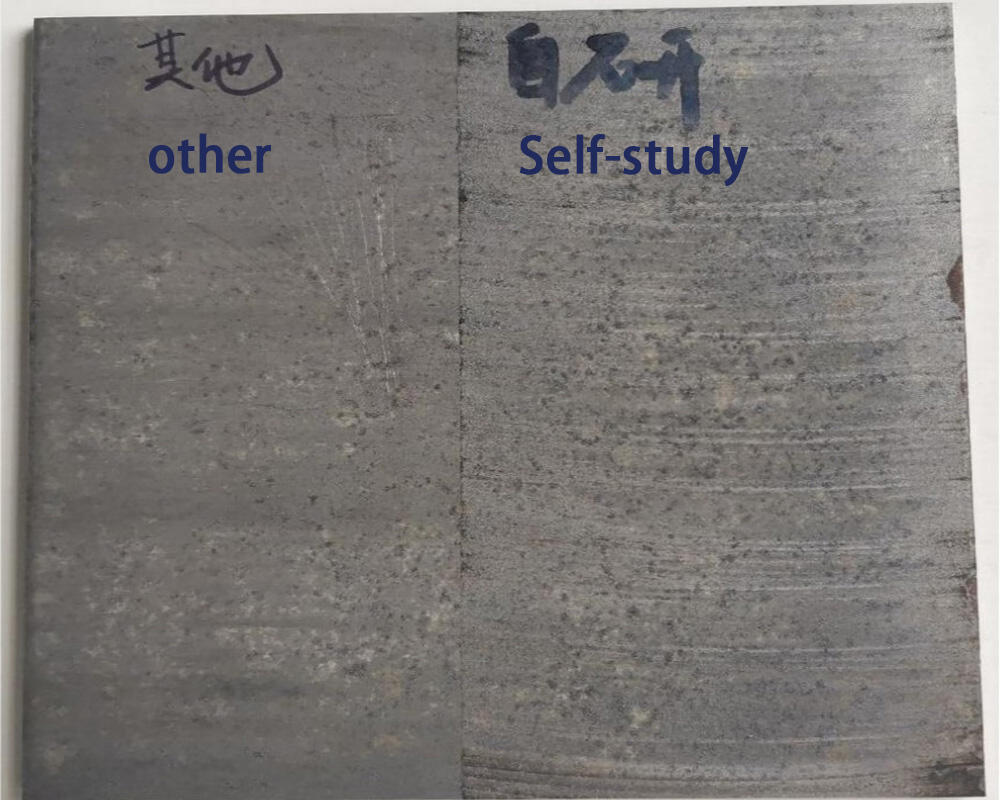

The cleaning effect of the oxide layer of carbon steel plate is shown in Figure 2. It can be seen from the picture that after cleaning the cleaning heads of other manufacturers twice, most of the oxide layer has not been cleaned, and most of the oxide layer has turned black due to thermal effects. However, the self-developed cleaning head can clean part of the oxide layer. After cleaning, the sample The surface of the piece is whiter and brighter.

Figure 2

Carbon steel plate corrosion cleaning effect

The effect of carbon steel rust cleaning is shown in Figure 3. As can be seen from the picture, both cleaning heads can clean the floating rust on the surface. However, after cleaning the cleaning heads of other manufacturers, most of the oxide layer at the bottom of the rust is not cleaned away, while the self-developed cleaning head can clean off part of the oxide layer. , the surface of the sample becomes whiter and brighter after cleaning.

Figure 3

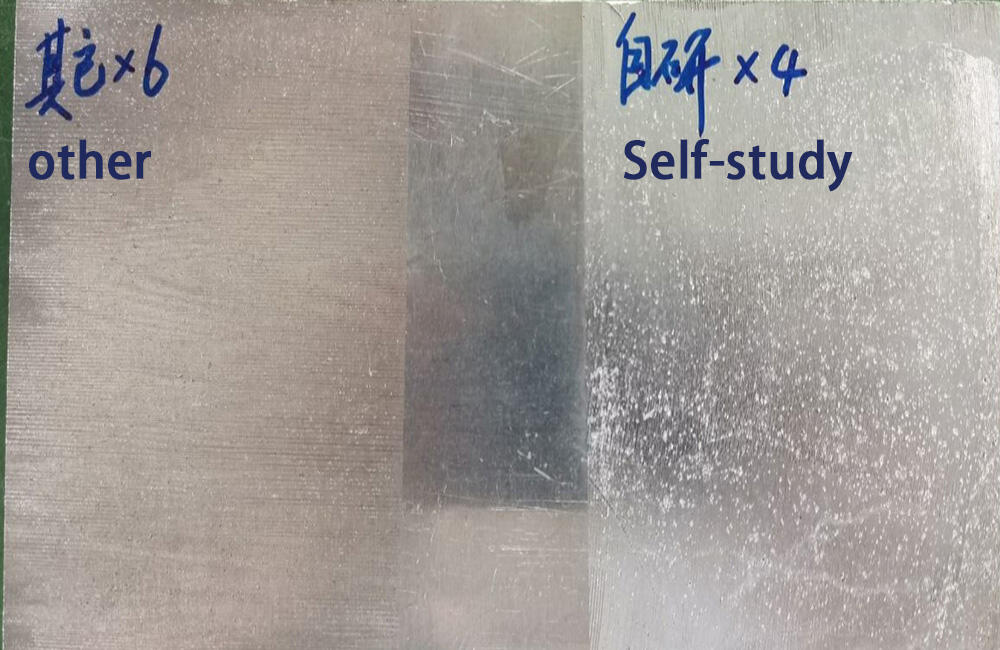

Aluminum alloy cleaning effect

The cleaning effect of aluminum alloy is shown in Figure 4. It can be clearly seen that due to the high reflectivity of aluminum alloy, the surface of aluminum alloy turns yellow after cleaning by other manufacturers' cleaning heads. The self-developed cleaning head can make the surface of aluminum alloy brighter after cleaning.

Figure 4

in conclusion

The self-developed cleaning head has better cleaning effect, and the texturing function can also improve the roughness well.

For More Details

|

|

|

|

Company Profile

Demark (Wuhan) Science & Technology Co.,Ltd Locates In Free Trade Zone Of East-Lake Hi-Tech Development District In Wuhan City, The Company Is Invested By High Level Technical And Managerial Professionals In China Laser Industry, With More Than 20 Years Working Experience In China Laser Cutting Industry, From The Intergration Of Laser Cutting Machine To The Operation Details Of Fabrication Factories, They Have Experienced The Time Changes And More Than Ten Thousand Installations All Over China, The Target Of Demark Is Exporting The Best Value Chain Of Chinese Laser Cutting Machine Or Fabricating Machineries To The Global Fabricators, To Be Your Best Partner When You Are Purchasing Laser Cutting Machine Or Fabricating Machineries In China With The Most Professional Service.

FAQ

Q1: What is your warranty policy?

A: For machines we offer 1-2 years warranty. Field support and online support is also available.

Q2: What is your after-sales service?

A: We got very professional engineers team with more than 20 years in this field, they can provide online support or machine repair to your country.

Q3: What is your advantage?

A: We are a professional and reliable factory, selling and repairing all models of laser machines with any brand. Purchasing Original and OEM for consumable parts is welcomed. We can also retrofit machines for your demands.

Q4: Can I get some discount if I order more ?

A: Yes, The more you order, the more you save.

Q5: How to choose suitable model?

A: Please provide a photo of the product you used before or advise us your needs, we will give suggestion.

Q6: What's your MOQ?

A: Normally one piece. If more, we can talk about discount. You can mix it with other laser machine parts shipping together.

Q7: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q8: What can you buy from us?

A: Laser Cutting Machine, Laser Welding Machine, Laser Cleaning Machine , Laser Source, Laser Machine Consumables.

Q9: Why should you buy from us not from other suppliers?

A: We have 20 years experience in laser cutting business and sheet metal fabrication industry, sourcing the best value chain of laser cutting machine and sheet metal fabrication machineries for the global fabricators is our target, professional and sincere.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR