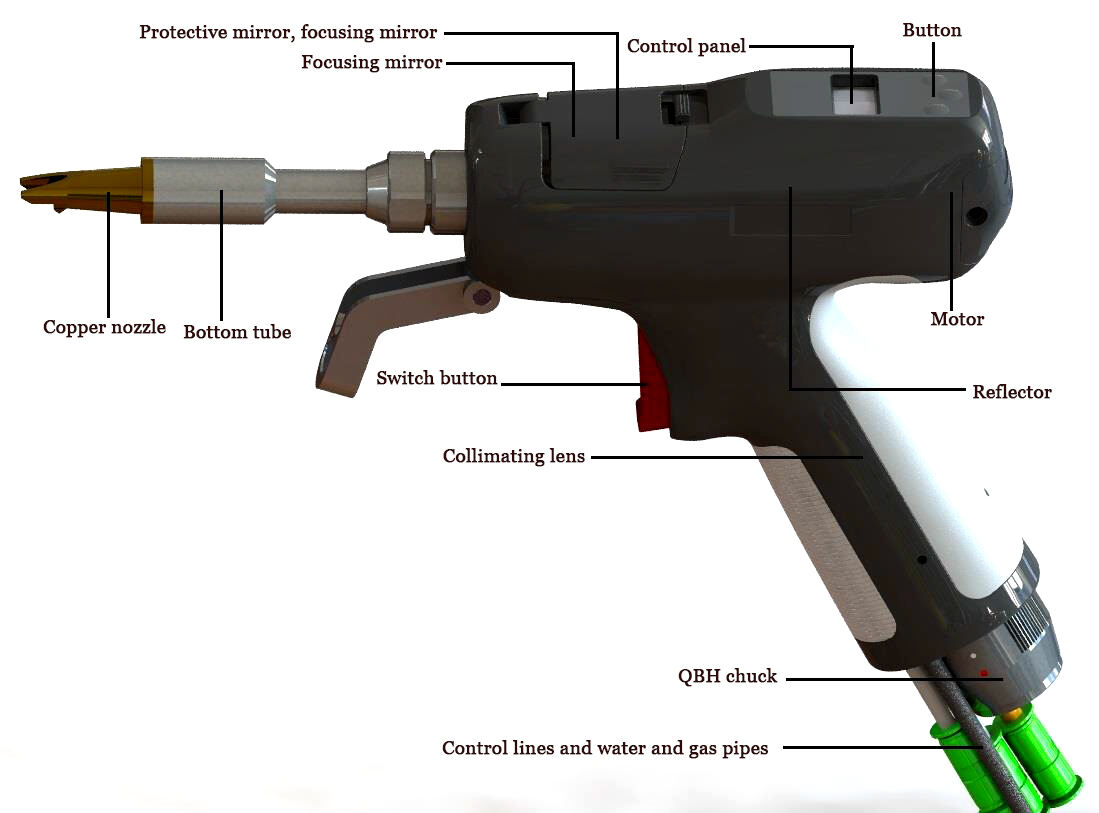

Au3tech HW980 Laser Welding Head

Product Description

HW980 is a handheld laser head that integrates functions such as welding, cleaning, cutting, and weld bead cleaning. Paired with the Mars9000P bus wire feeder and cleaning kit, the handheld laser processing method has more functions and better processing results.

Laser welding is a new welding method, and handheld laser welding is more widely used. The handheld laser welding head has a beautiful appearance, is compact and lightweight, has a wide range of uses, is simple to operate, and has fine and beautiful welds, which greatly improves welding efficiency and quality. Handheld laser welding solves the existing welding problems such as difficult welding of corners, insufficient welding, post-processing of welds, unsightly welds, etc. It is the preferred method for welding most metals.

Features

| * Ergonomic appearance design, simple single-line communication * Gun-mounted control unit quickly adjusts parameters at the gun head * Controlled wire feeding and withdrawal, double protection lens design reduces the chance of intracavity contamination * The maximum cleaning spot of 120mm improves cleaning efficiency |

|

|

* Shockproof and drop-proof design to protect the gun head * Motor controller integrated into the gun head * Strong anti-interference ability, integrating multiple functions such as welding, cleaning, cutting and weld bead cleaning |

Product Parameters

| Max Power | 3000W |

| Focus Lens | D20F150(D20F600 For cleaning use) |

| Collimator Lens | D20F50 |

| Cover Lens | D20T3 |

| Head Weight | 0.6kg(head only) |

| Max cleaning beam width | 120mm |

| Wobble Frequency | 0-200HZ |

| Fiber Sockets | QBH and Customized |

For More Details

|

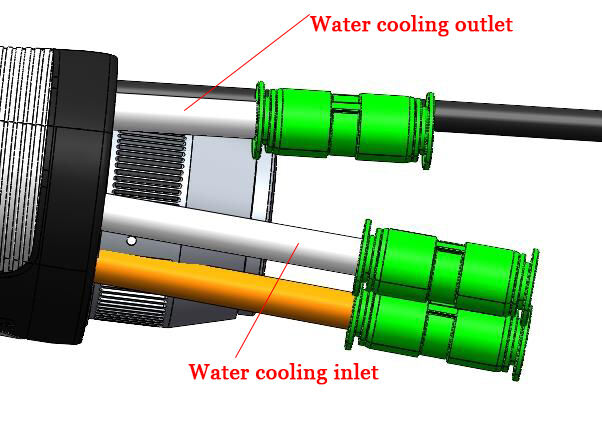

The HW980 handheld welding head is equipped with a set of cooling water channels. It should be noted that it is recommended to use water cooling when the laser power is greater than 500 watts. |

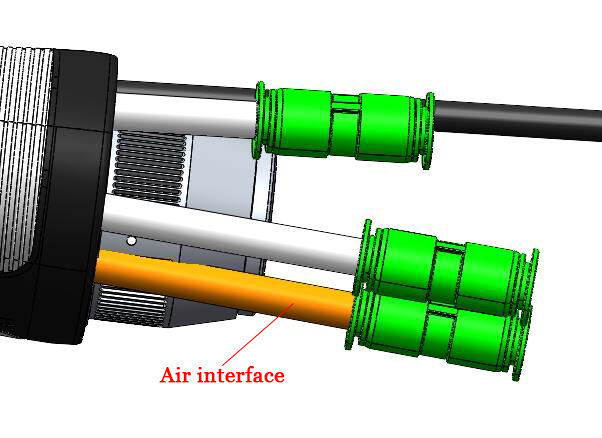

Impurities in the welding gas such as hydrocarbons and water vapor will damage the lens. The following table is the recommended welding gas specifications. The higher the purity of the gas, the better the quality of the welding gap. |

|

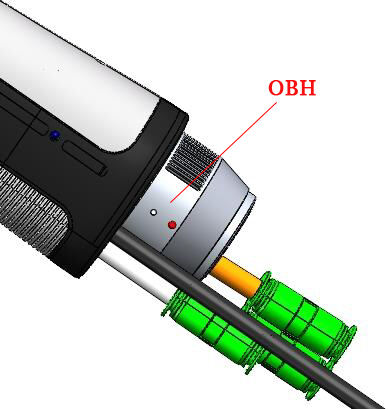

HW980 is suitable for most industrial laser generators. It is equipped with its own collimating lens assembly. |

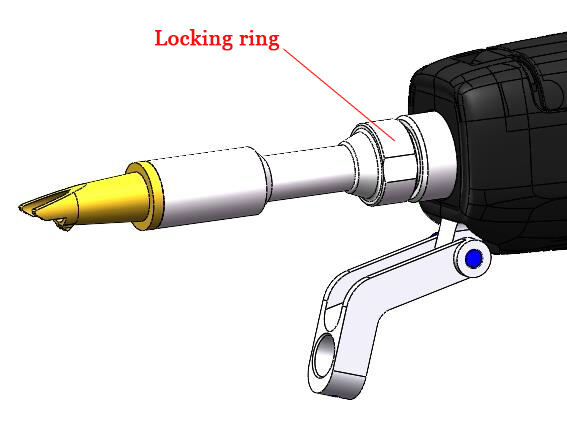

The welding head can adjust the focus position. The adjustment method is to rotate the locking ring counterclockwise. After loosening, adjust the length of the copper nozzle to obtain the required spot energy. After adjusting the position, tighten the locking ring and The copper nozzle is locked in the position just adjusted.There is a scale on the copper nozzle, making it easy and quick to adjust. |

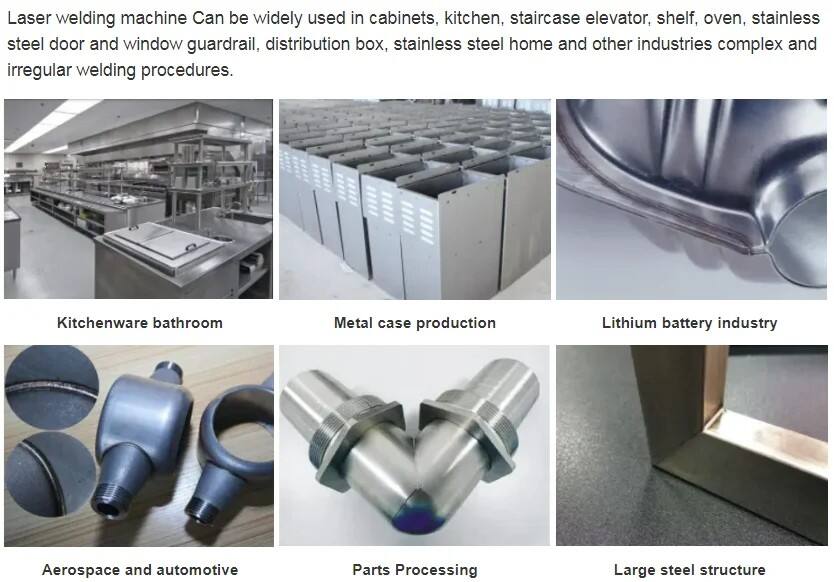

Application

Company Profile

Demark (Wuhan) Science & Technology Co.,Ltd Locates In Free Trade Zone Of East-Lake Hi-Tech Development District In Wuhan City, The Company Is Invested By High Level Technical And Managerial Professionals In China Laser Industry, With More Than 20 Years Working Experience In China Laser Cutting Industry, From The Intergration Of Laser Cutting Machine To The Operation Details Of Fabrication Factories, They Have Experienced The Time Changes And More Than Ten Thousand Installations All Over China, The Target Of Demark Is Exporting The Best Value Chain Of Chinese Laser Cutting Machine Or Fabricating Machineries To The Global Fabricators, To Be Your Best Partner When You Are Purchasing Laser Cutting Machine Or Fabricating Machineries In China With The Most Professional Service.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR