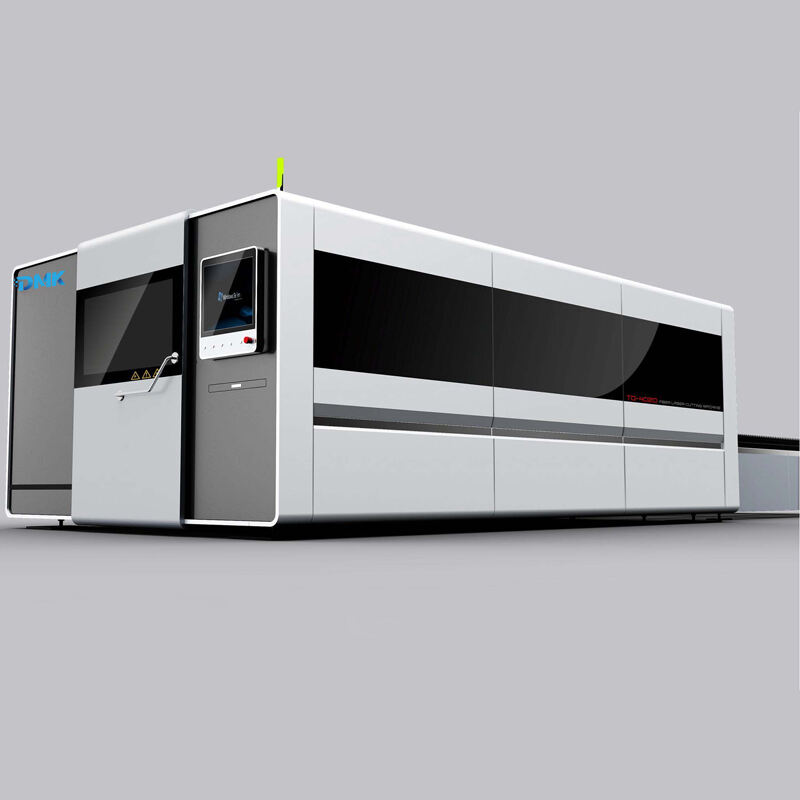

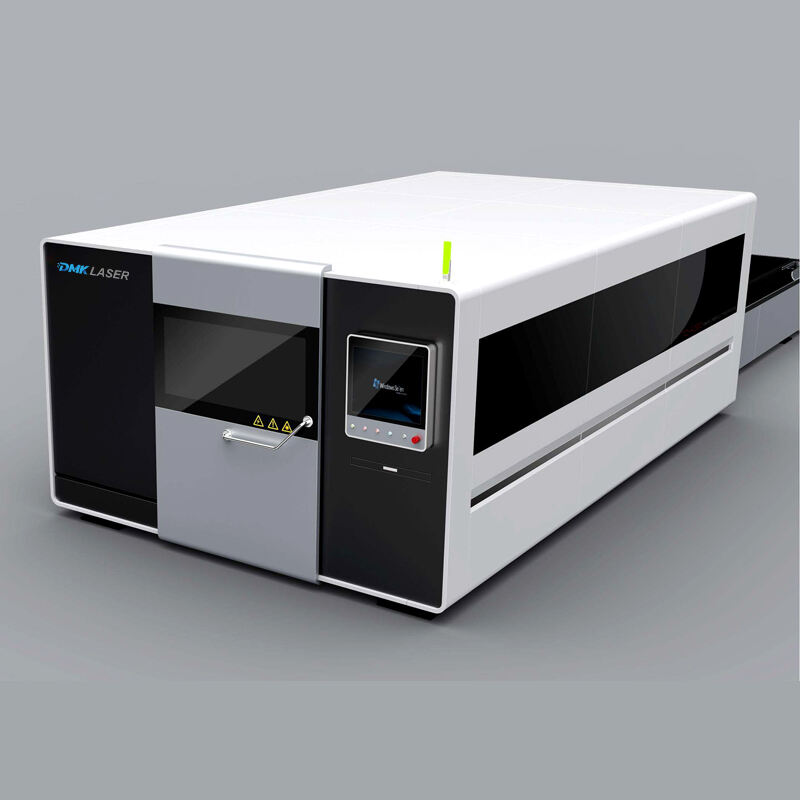

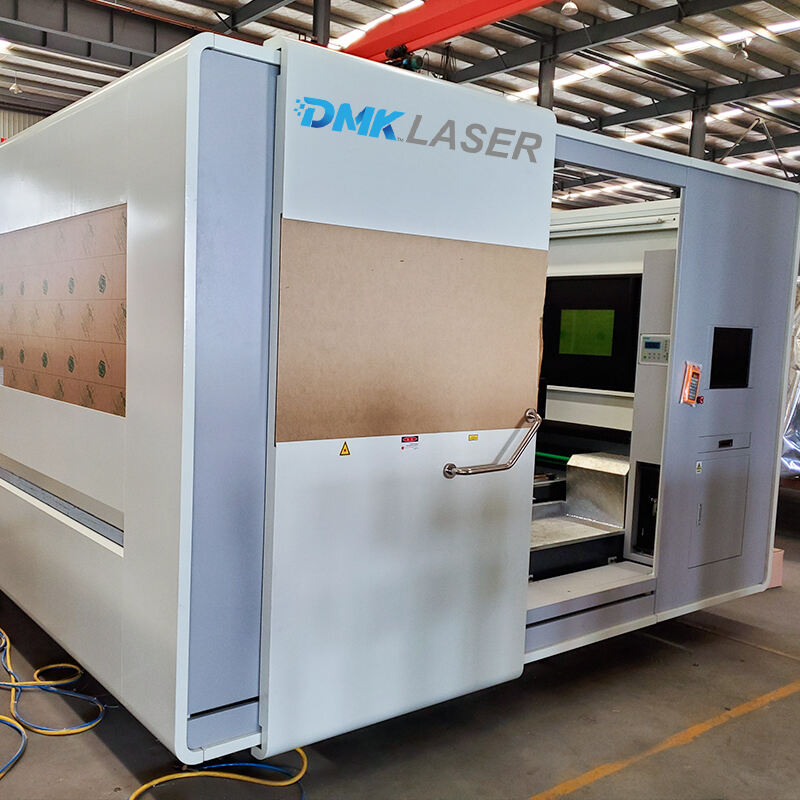

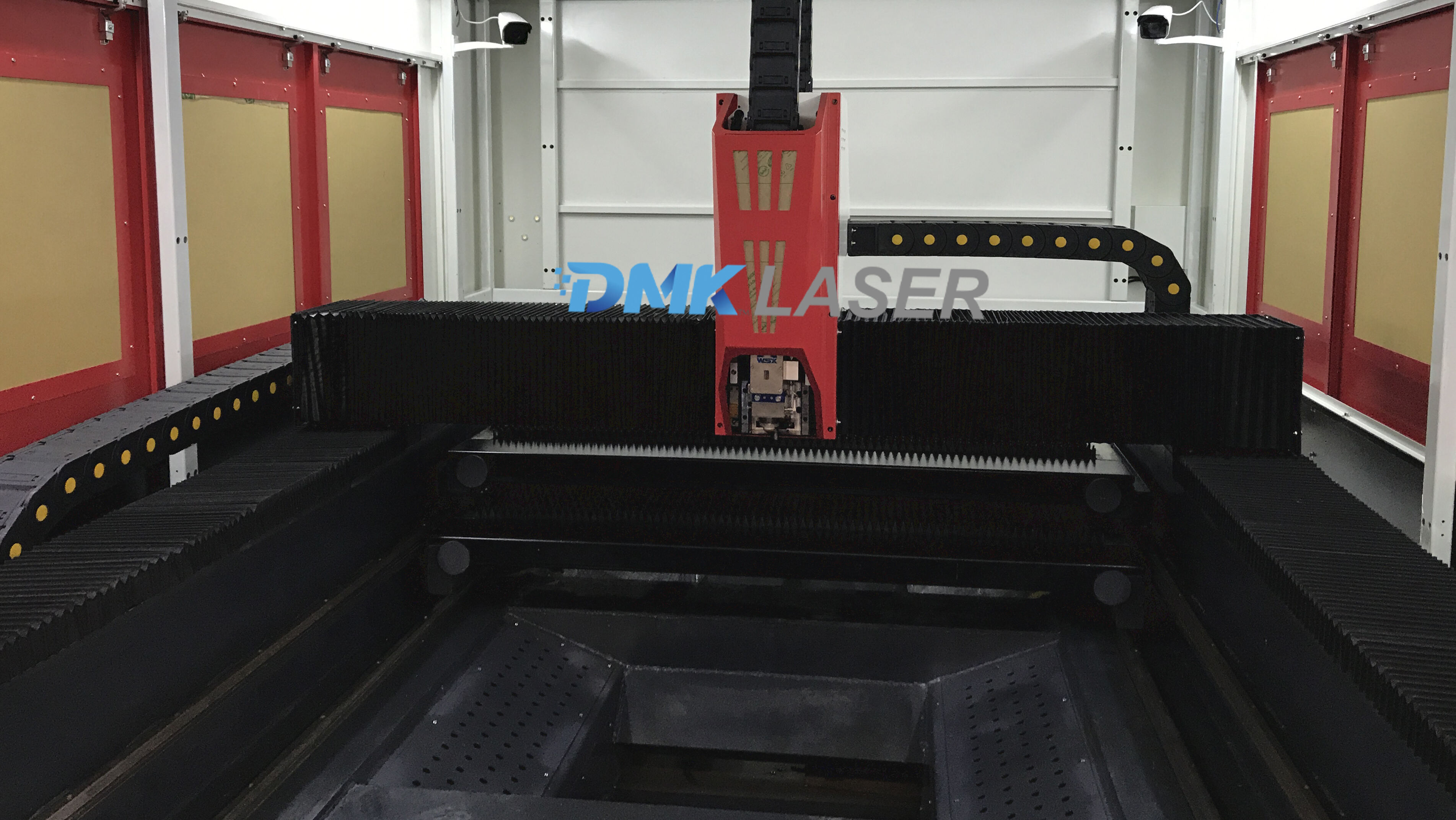

6000W Dual Table Enclosure Type Sheet Laser Cutting Machine

| Product Description | |

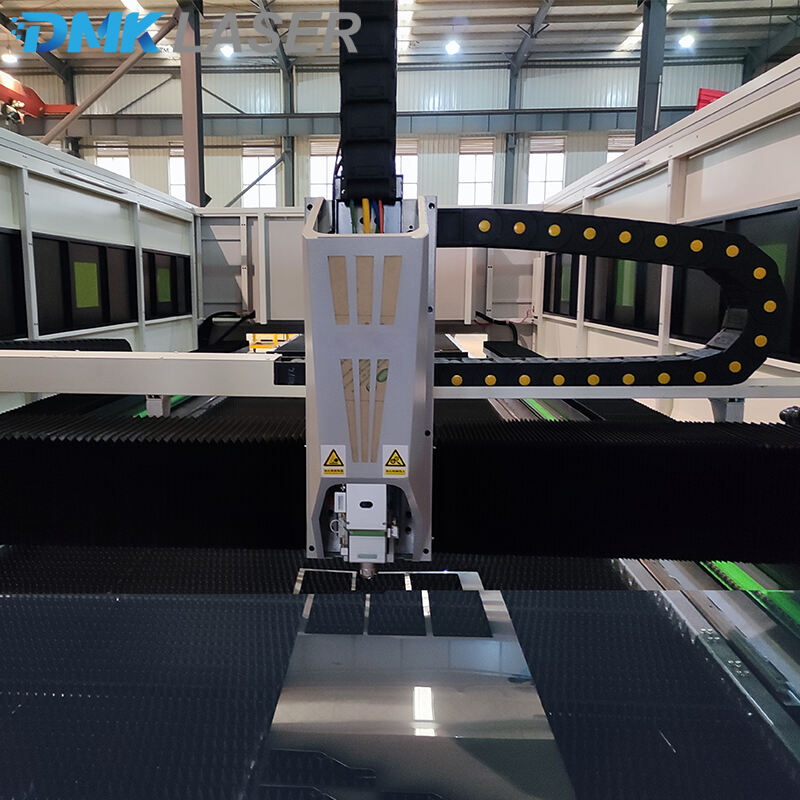

| This product adopts a gantry dual-drive structure. The bed is an integral weldment, and the crossbeam is welded with marine steel plates. Both are rough-machined after annealing, and then fine-machined as a whole after secondary artificial heat aging treatment, achieving extremely high geometric tolerance accuracy; In terms of transmission, it is equipped with Motory high-rigidity precision reducer, KH ground gear rack, HIWIN high-precision linear guide and other efficient transmission mechanisms, with good rigidity and high precision, ensuring long-term high-precision operation; it is assembled through an advanced CNC system and is a precision CNC fiber laser cutting machine that integrates laser cutting, precision machinery, CNC technology and other disciplines. | |

|

|

|

|

|

| Specifications | |

|

Processing area and working range |

|

|

Processing area (length × width) |

3000mm×1500mm |

|

X-axis travel |

1500mm |

|

Y-axis travel |

3000mm |

|

Z-axis travel |

280mm |

|

Accuracy |

|

|

X, Y axis positioning accuracy |

±0.03mm/m |

|

X, Y axis repeat positioning accuracy |

±0.02mm |

|

speed |

|

|

X, Y axis maximum positioning speed |

120m/min |

|

X, Y axis maximum acceleration |

1.5G |

|

Power parameters |

|

|

Number of phases |

3 |

|

Power supply rated voltage |

380V |

|

frequency |

50Hz |

|

Total power protection level |

IP54 |

|

Weight and dimensions |

|

|

Maximum load of workbench |

8000kg |

|

Machine weight |

About 13000Kg |

| Main configuration of the product | |||

|

Serial number |

Name |

Model |

Quantity |

|

1 |

High power fiber laser cutting machine |

TQL-3015WB-60G |

1 set |

|

2 |

Laser Source |

RFL-6000 |

1 set |

|

3 |

Laser Chiller |

HL-6000 |

1 set |

|

4 |

Dust removal fan |

5.5KW |

1 set |

|

5 |

Cutting head |

Automatic focus |

1 set |

| Application |

1. Suitable for cutting space: two-dimensional plane cutting. + pipe cutting (pipe diameter less than 220mm).

2. Application industries: aerospace, rail transit, shipbuilding, automobiles, engineering machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, grain machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchenware and bathroom, decoration advertising, laser external processing services and other machinery manufacturing and processing industries.

3. Cutting materials: carbon steel, stainless steel, aluminum alloy, brass, copper, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy.

4. Cutting range: high-quality cutting of 0.5-30mm carbon steel, 0.5-20mm stainless steel, aluminum alloy 0.5-16mm, brass 0.5-10mm.

5. Unique cutting function: flying fast cutting technology, ≤6mm carbon steel 0.5 second perforation technology, ≤8mm stainless steel, aluminum alloy compressed air cutting technology, etc.

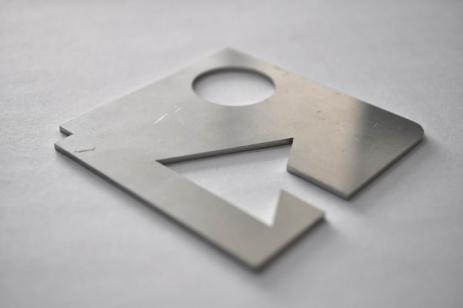

Typical cutting samples

|

|

|

| Material: Carbon steel | Material: Stainless steel | Material: Carbon steel |

|

|

|

| Material: Stainless steel | Material: Aluminum alloy | Material: Brass, copper |

| Company Profile |

Demark (Wuhan) Technology Co.,Ltd has focused on laser technology for over 20 years in China, including laser marking, laser welding, laser cleaning and laser cutting applications. We started as a small operation, but now have become one of the leading suppliers in the laser industry in China.

Today, Demark (Wuhan) Technology Co.,ltd has been one of the top manufacturers of laser machine and laser equipment parts, such as: laser cutting machine, laser welding machine, laser cleaning machine and laser surface treatment equipment.

FAQ

Q1: What is your warranty policy?

A: For machines we offer 1-2 years warranty. Field support and online support is also available.

Q2: What is your after-sales service?

A: We got very professional engineers team with more than 20 years in this field, they can provide online support or machine repair to your country.

Q3: What is your advantage?

A: We are a professional and reliable factory, selling and repairing all models of laser machines with any brand. Purchasing Original and OEM for consumable parts is welcomed. We can also retrofit machines for your demands.

Q4: Can I get some discount if I order more ?

A: Yes, The more you order, the more you save.

Q5: How to choose suitable model?

A: Please provide a photo of the product you used before or advise us your needs, we will give suggestion.

Q6: What's your MOQ?

A: Normally one piece. If more, we can talk about discount. You can mix it with other laser machine parts shipping together.

Q7: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q8: What can you buy from us?

A: Laser Cutting Machine, Laser Welding Machine, Laser Cleaning Machine , Laser Source, Laser Machine Consumables.

Q9: Why should you buy from us not from other suppliers?

A: We have 20 years experience in laser cutting business and sheet metal fabrication industry, sourcing the best value chain of laser cutting machine and sheet metal fabrication machineries for the global fabricators is our target, professional and sincere.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR