500W Air-Cooled Continuous Fiber Laser

| Product Description |

Compact. Efficient. Versatile.

The YDFL-500-CW-SM-A-HW is a high-performance, air-cooled, single-module Yb-doped continuous wave fiber laser developed for industrial-grade laser processing. With a rated output power of 500W, it delivers excellent beam quality and stability, making it ideal for applications such as laser welding, laser cleaning, and laser cutting.

| Key Features |

|

🔧 Air-Cooled Design Efficient heat dissipation in a compact form factor—no external water chiller required. |

|

|

🎯 Excellent Beam Quality M² ≤ 1.5, ensuring precise and clean processing with minimal thermal effects. |

| 🔄 Stable Output Power Power instability ≤ 3% (steady state) for consistent performance in high-precision tasks. |

|

|

🔍 Red Guide Laser Built-In Integrated 0.9 mW red guide laser for easy alignment and safer operation. |

|

🔌 Plug-and-Play Integration Supports RS232 communication, TTL trigger, and analog control (0-10V), compatible with a wide range of CNC systems and industrial automation setups. |

|

| Specifications |

| Parameter | Specification |

|---|---|

| Model | YDFL-500-CW-SM-A-HW |

| Operation Mode | Continuous Wave (CW) / Quasi-CW |

| Output Power | 500W |

| Central Wavelength | 1080 ± 10 nm |

| Beam Quality (M²) | ≤ 1.5 |

| Polarization | Random |

| Modulation Frequency | Up to 5 kHz |

| Power Tuning Range | 10% – 100% |

| Delivery Cable | 5 meters QBH standard (customizable) |

| Core Diameter | 14 μm |

| Cooling Method | Air-cooled |

| Power Supply | 220V ±10%, 50/60 Hz |

| Max Power Consumption | 1800W |

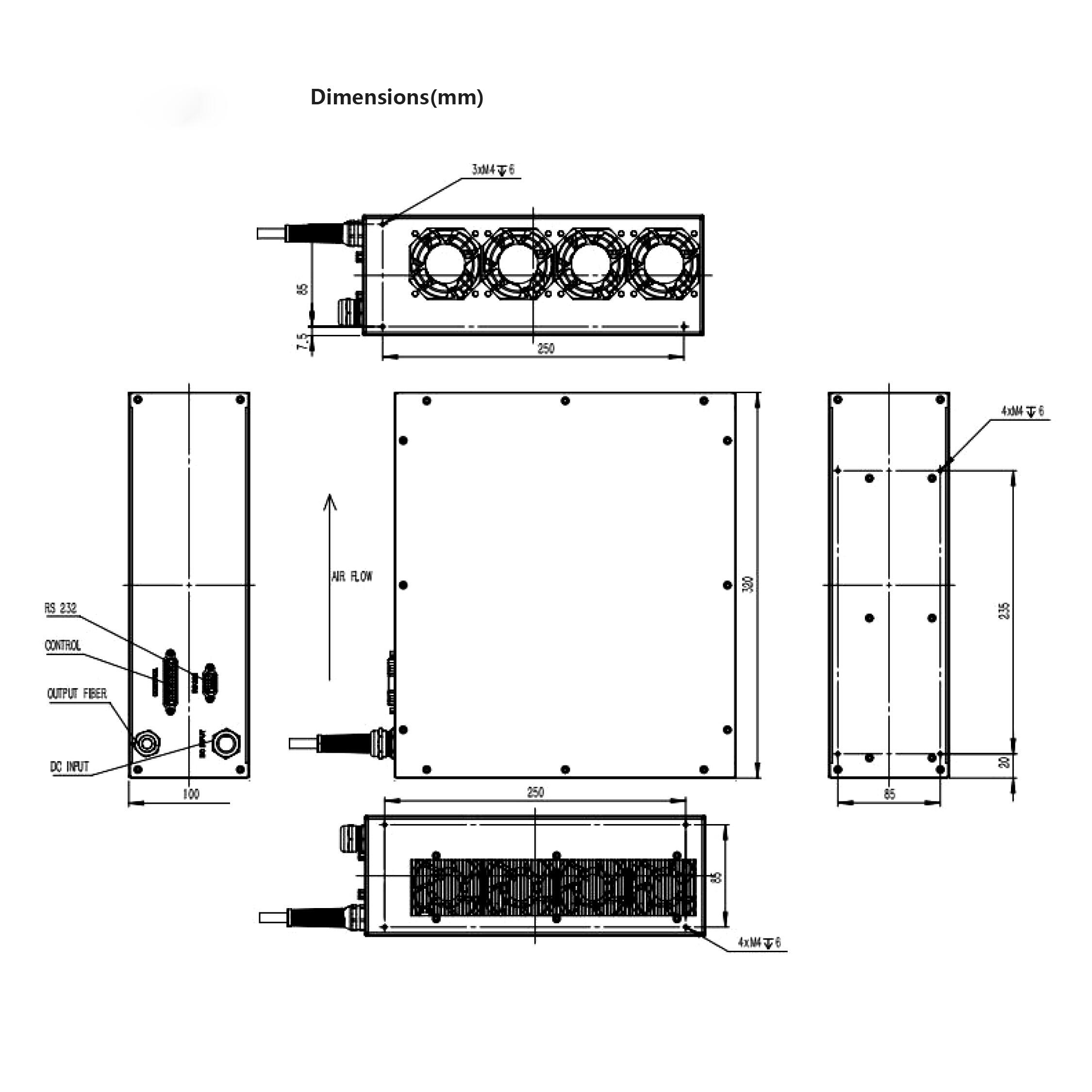

| Dimensions (L×W×H) | 320 × 283 × 100 mm |

| Weight | ≤ 9 kg |

| Operating Temp. | 0°C ~ +40°C |

| Storage Temp. | -20°C ~ +60°C |

| Humidity | 10% – 85% RH (non-condensing) |

| Applications |

Laser Welding: Suitable for high-precision metal welding tasks with excellent seam quality.

Laser Cleaning: Effectively removes rust, oil, and coatings without damaging the substrate.

Laser Cutting: Clean cutting of thin metal sheets with smooth edges and high speed.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR