3000W hanli Handheld Laser Welding Cleaning Cutting 3-in-1 Machine

| Product Description | ||

|

A welding chiller case is a type of equipment used in industrial welding applications to cool down the welding torch or gun. This is necessary because as the torch or gun heats up during use, it can become overheated and affect the quality of the weld. The chiller case helps to regulate the temperature and maintain optimal welding conditions. |

| Product Parameters |

| Model | SCHYTJ-3000 | |

| Voltage & Frequency | AC 1P 220 V | |

| Working power | 50Hz | 60Hz |

| Working current | 13.5 A | 13.5 A |

| Machine power | 3.9 kW | 3.9 kW |

| Application environment | 0℃<Environment temperature<45℃ , Relative humidity<95% | |

| Tempe.control accuracy | ±1 ℃ | |

| Coolant | R32 | |

| Cooling capacity | 7.1 kW | |

| Electric heating power | 600W (room temperature) | |

| Rated flow of water pump | 1.2 m³/h | |

| Max.pump lift | 40 m | |

| Pump power | 0.48 kW | |

| Tank volume | 13 L | |

| Matching Laser tube | G1/2*φ20mm Pagoda hose connector | |

| QBH head nozzle interface | Φ6mm pneumatic quick connector | |

| Dimension | 1125×520×880 (mm) | |

| N.W | 79.5KG | |

| Packing size | 1170×565×1030 (mm) | |

| G.W | 96.5 kg | |

| Matching laser source |

3000W Continuous fiber lase (Matching BWT,Max,Raycus ,RECI laser) |

|

| Product Features |

|

1.A chiller for a 3000W laser welding machine is an essential component to maintain optimal operating temperature of the laser system. The chiller works by circulating coolant through the laser optics and the laser source, preventing overheating and maintaining the quality of the laser beam. 2.to ensure consistent and high-quality welding results,It is important to choose the right chiller for the laser welding machine to ensure compatibility and efficiency. Regular maintenance and cleaning of the chiller is also necessary to prevent clogs and prolong its lifespan. 3.The chiller is responsible for maintaining the temperature of the laser system, which is critical for the quality and precision of the welding process. |

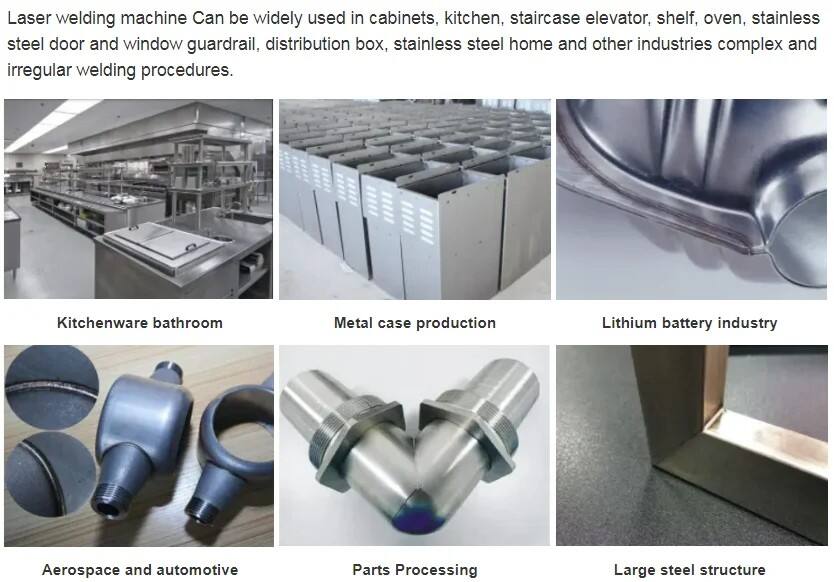

| Application |

|

| Company Profile |

|

Demark (Wuhan) Science & Technology Co.,Ltd Locates In Free Trade Zone Of East-Lake Hi-Tech Development District In Wuhan City, The Company Is Invested By High Level Technical And Managerial Professionals In China Laser Industry, With More Than 20 Years Working Experience In China Laser Cutting Industry, From The Intergration Of Laser Cutting Machine To The Operation Details Of Fabrication Factories, They Have Experienced The Time Changes And More Than Ten Thousand Installations All Over China, The Target Of Demark Is Exporting The Best Value Chain Of Chinese Laser Cutting Machine Or Fabricating Machineries To The Global Fabricators, To Be Your Best Partner When You Are Purchasing Laser Cutting Machine Or Fabricating Machineries In China With The Most Professional Service.

|

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR