200W Jewelry Spot Laser Welding Machine

Product Description

Laser spot welding is an essential part of the laser materials processing technology application, which belongs to heat conduction type. That is the surface of the workpiece heated by laser radiation, heat diffuses inside through heat conduction, by controlling the parameters of laser pulse width, energy, peak power and repetition frequency, the workpiece is melted to form a specific molten pool. For its unique advantages, laser spot welder has been widely used in the processing of jewelry and welding of micro or small components.

The laser spot welder is applied to jewelry ornaments manufacturing, jewelry repairing, rings or bracelets resizing, gold and silver re-tipping, stone setting, eyewear welding or repairing, denture welding, small auto parts welding, etc. Generally, it is especially suitable for tiny target precision welding. It works on gold, platinum, titanium, silver, copper, nickel, aluminum, magnesium, stainless steel, etc.

|

|

Two colors to choose from, blue and red

Application & Samples

This vertical cabinet type jewellery welding machine is widely used in the fine processing of tiny parts, such as rings, pendants, bracelets, dentures, mobile phone charger interface, hardware, clocks and watches, aviation, aerospace sporting goods, golf head, medical equipment, stainless steel, titanium alloy decorations, spectacle frames, especially for gold and silver jewellery to fill the holes, spot weld the seams, inlays, and other welding parts.

|

Laser welding is capable of welding many materials compared to other welding processes and compares favourably with low thermal deformation of welded components and high quality joints. |

| Laser welding has the advantage of being able to achieve a very small range of local heating characteristics, and is widely used in precision devices such as jewellery, batteries, the automotive industry, the aerospace industry and a number of other applications. |  |

Technical Parameters

|

Maximum average power |

200W |

300W |

400W |

|

Laser wavelength |

1064nm |

1064nm |

1064nm |

|

Max Pulse energy |

80J |

90J |

110J |

| Batter, laser welding frequency |

1~100Hz |

1~100Hz |

1~100Hz |

|

Aim operation |

Round point cursor |

Round point cursor |

Round point cursor |

|

Cooling system |

Built-in |

Built-in |

Built-in |

|

Adjustable range of spot size |

0.1~3mm |

0.1~3mm |

0.1~3mm |

|

Control system |

Industrial computer |

Industrial computer |

Industrial computer |

|

Machine Power consumption |

≤6kw |

≤9kw |

≤12kw |

|

Lifetime |

3,000,000 times |

3,000,000 times |

3,000,000 times |

|

Humidity |

5% to 75%non-condensing. |

5% to 75%non-condensing. |

5% to 75%non-condensing. |

|

Power supply |

220V±0%/50Hz |

380V±0%/50Hz |

380V±0%/50Hz |

|

Supplies |

Xenon lamp, filter, protection lens, argon gas |

Xenon lamp, filter, protection lens, argon gas |

Xenon lamp, filter, protection lens, argon gas |

|

Environment |

clean, no dust or less dust |

clean, no dust or less dust |

clean, no dust or less dust |

|

Machine dimension |

95*55*65cm |

95*55*65cm |

95*55*65cm |

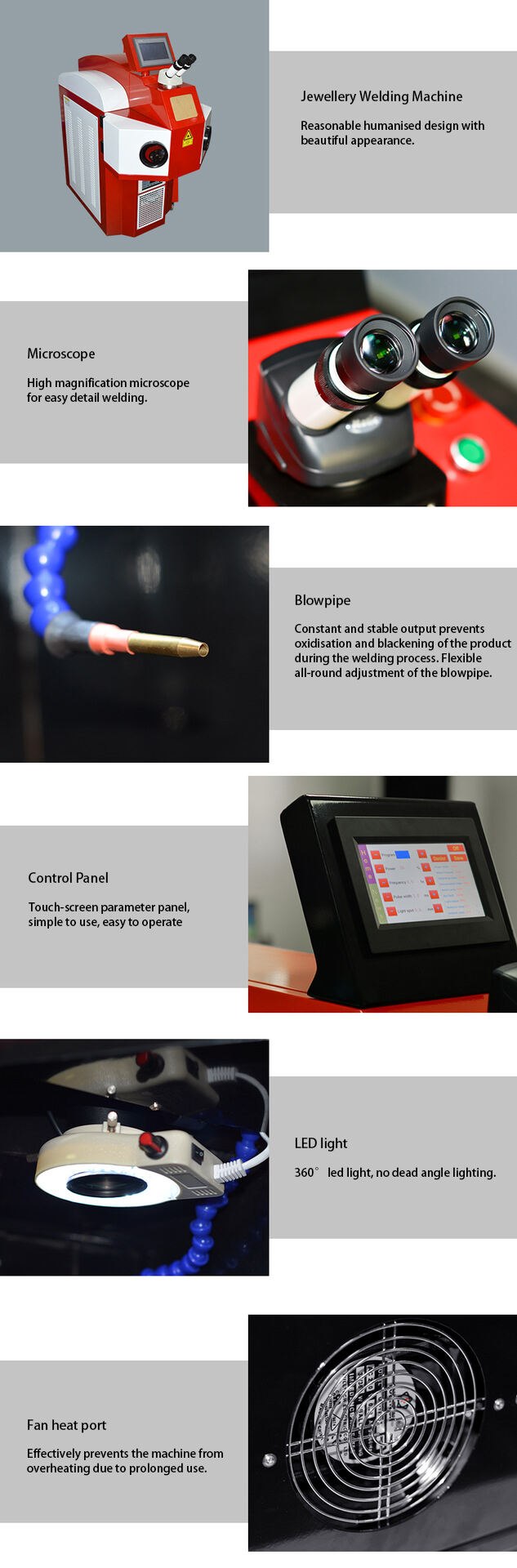

Features

1.Energy, pulse width, frequency and focus can be adjusted within a wide range to achieve different welding effects.

2.Ceramic reflector used in the laser pump chamber is imported, which is corrosion resistant, high temperature resistant, high electrical/optical conversion.

3.World-leading automatic light shielding system is employed to remove harmful lighting on eyes during operation.

4.24-hour continuous operation, with stable operating performance.

5.Free of maintenance within 10000 hours.

6.Personalized design in compliance with ergonomics principles.

7.High efficiency and high quality welding, large depth and small deformation, solder joint pollution-free andenvironmental protection.

|

|

|

|

For More Details

Company Profile

Demark (Wuhan) Technology Co., Ltd is a high-tech enterprise focusing on the research and development, production, sales and service of fiber laser equipment. It is headquartered in Wuhan Optics Valley, the birthplace of laser technology in China. Relying on the solid scientific research strength of Huazhong University of Science and Technology, the company has mastered a number of core technologies in laser cutting, welding, cleaning and marking through more than 20 years of exploration and accumulation, and has more than 60 patent protections. FAQ

FAQ

Q: What maintenance is required for a Jewelry Laser Welding Machine?

A: Maintenance requirements vary depending on the model and usage of the Jewelry Laser Welding Machine. Generally, regular cleaning and inspection of the machine's components is recommended to ensure its proper functioning. Additionally, some machines may require periodic replacement of certain parts, such as flash lamps or laser tubes.

Q: Can a Jewelry Laser Welding Machine be used for engraving or marking jewelry?

A: Some Jewelry Laser Welding Machines may have the capability to engrave or mark jewelry, but it is not their primary function. For engraving or marking, a dedicated laser engraving or marking machine would be more appropriate.

Q: How long does it take to learn how to use a Jewelry Laser Welding Machine?

A: Learning how to use a Jewelry Laser Welding Machine can vary depending on the individual and their level of experience with welding and metalworking. With proper training and practice, beginners can usually become proficient in a few weeks.

Q: Can a Jewelry Laser Welding Machine be used on all types of jewelry?

A: While a Jewelry Laser Welding Machine can be used on a wide range of jewelry materials, there may be some materials or designs that are not suitable for laser welding. It is important to consult with an experienced jewelry technician or manufacturer to determine the best approach for your specific project.

Q: Are there any limitations to the size or shape of jewelry that can be welded with a Jewelry Laser Welding Machine?

A: The size and shape of the jewelry that can be welded with a Jewelry Laser Welding Machine may be limited by the size and shape of the machine's welding chamber or by the positioning and movement of the jewelry during welding. It is important to choose a machine with an appropriate size and shape for your specific needs.

Q: Can a Jewelry Laser Welding Machine be used to repair gemstones or other non-metal components of jewelry?

A: No, a Jewelry Laser Welding Machine is not designed to repair or work on non-metal components of jewelry, such as gemstones or beads. These components may be damaged or destroyed by the high heat of the laser welding process.

Q: What is the difference between a Jewelry Laser Welding Machine and a traditional soldering iron or torch?

A: A Jewelry Laser Welding Machine uses a high-energy laser beam to melt and weld metal pieces together, while a traditional soldering iron or torch uses heat to melt and join metal. Laser welding allows for more precise and controlled welds, minimal heat affected zone, and the ability to weld difficult-to-reach areas.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR