Laser welding technology process manufacturing applicationA reliable and complete application of laser welding technology requires verification from multiple aspects including laser welding process parameters, joint performance combined wit...

Contact Us

Laser welding technology process manufacturing application

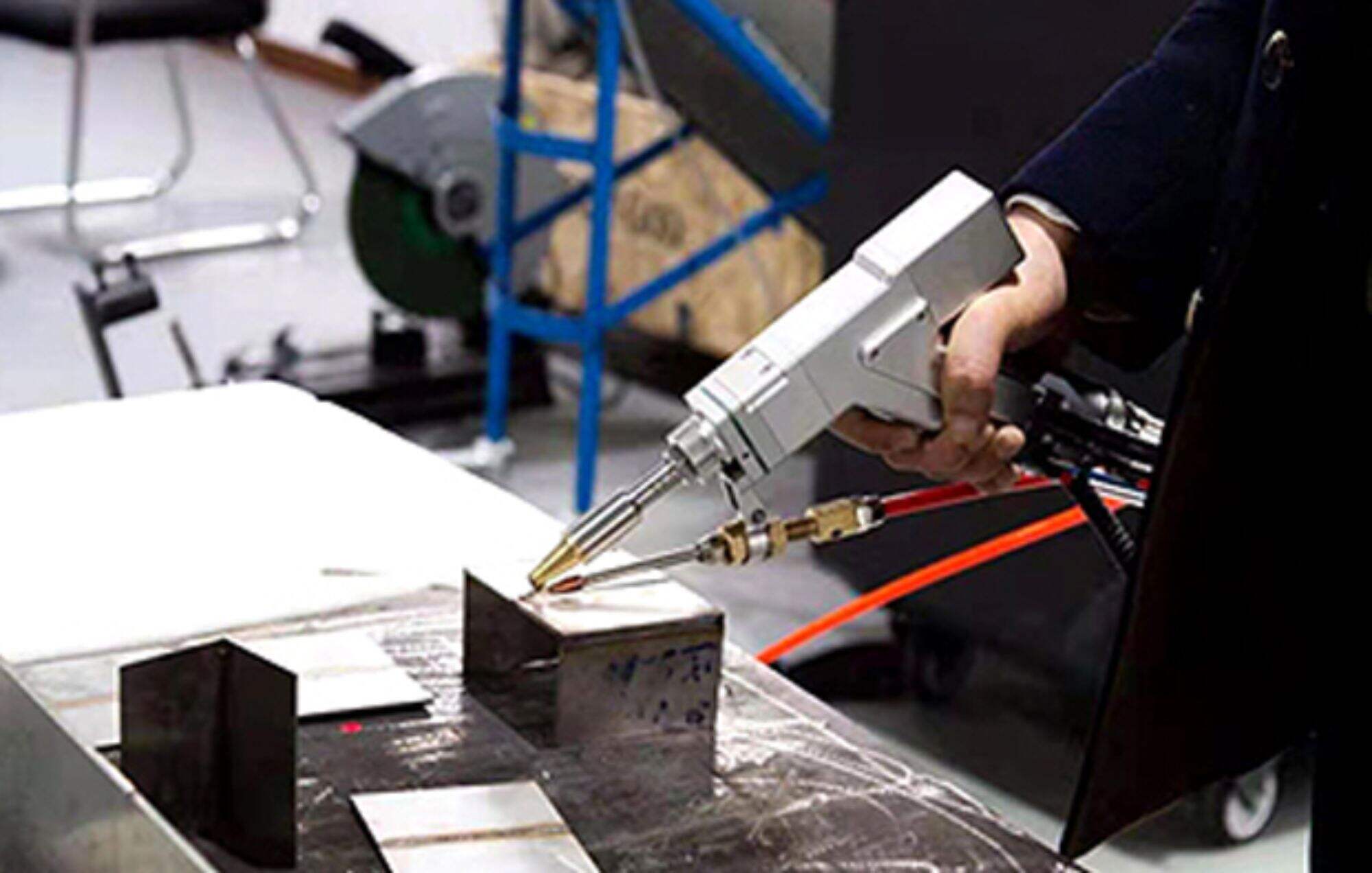

A reliable and complete application of laser welding technology requires verification from multiple aspects including laser welding process parameters, joint performance combined with numerical simulation, only then can we form process parameters suitable for vehicle manufacture.

1.1 Research on optimal process parameters

Following the standard of no welding traces on the outer surface and a strength higher than that of resistance spot welding, laser welding process tests were conducted on stainless steel plates with different thickness combinations. As a result, we concluded the optimal parameter combination for laser welding of the stainless steel body.

(1) Laser power

In laser welding, there exists a threshold of laser energy density. Below this value, the melting depth is very shallow. Once this value is reached or exceeded, the depth of melting drastically increases. Plasmas only form when the laser power density on the workpiece exceeds the threshold (which is material-dependent), signifying the progress of stable deep fusion welding.If the laser power is below this threshold, only surface melting of the workpiece occurs, and the welding process is carried out in a stable heat conduction mode. However, when the laser power density is near the critical conditions for the formation of tiny holes, deep fusion welding and conduction welding alternate, leading to an unstable welding process, which in turn results in significant fluctuations in the depth of melting.During laser deep penetration welding, the laser power controls both the penetration depth and welding speed simultaneously. The welding penetration depth is directly related to the beam power density, and it is a function of the incident beam power and the beam's focal spot.Generally speaking, for a laser beam of a certain diameter, the depth of melting increases as the beam power increases.

(2) Welding speed

The welding speed has a significant effect on the melting depth. Increasing the speed will make the melting depth shallower, but if the speed is too low, it can cause excessive melting of the material and welding penetration of the workpiece.Therefore, for a certain laser power and a particular material of a certain thickness, there is an appropriate welding speed range, and the maximum depth of melting can be obtained at the corresponding speed value.

(3) Beam focal spot.

The size of the beam spot is one of the most important variables inlaser weldingbecause it determines the power density.However, for high-power lasers, measuring this is a challenge, despite the presence of many indirect measurement techniques.The diffraction limit spot size of the beam focus can be calculated according to the theory of light diffraction, but due to the existence of aberrations in the focusing lens, the actual spot is larger than the calculated value.The simplest practical test method is the Equal Temperature Contour method, which involves scorching a thick piece of paper and after penetrating a polypropylene board, the focus spot and the diameter of the hole are measured. This method relies on practical testing to accurately gauge the size of the laser's power and the time of the laser beam's action.

(4)Focus position

During welding, to maintain sufficient power density, the focal point position is critical.The positional change of the focus relative to the surface of the workpiece directly affects the width and depth of the weld. Laser welding usually requires a certain degree of defocusing because the power density at the center of the beam spot where the laser is focused is too high, which can easily lead to vaporization and punching holes.On each plane moving away from the laser focus, the power density distribution is relatively uniform. There are two types of defocusing: positive defocusing and negative defocusing. When the focal plane is above the workpiece, it is referred to as positive defocusing, and vice versa, it is known as negative defocusing.According to geometric optics theory, when the positive and negative defocus planes are at an equal distance from the welding plane, the power density on the corresponding planes is approximately the same. However, the actual shape of the weld pool obtained is different.During negative defocus, a greater fusion depth can be obtained, which is related to the formation process of the weld pool. Experiments have shown that materials begin to melt after 50~200 μs of laser heating, forming liquid metal and vaporizing to create room pressure steam, which jets out at an extremely high speed, emitting dazzling white light.At the same time, the high concentration of gases propels the liquid metal towards the edges of the weld pool, creating a depression in the middle of the weld pool. When defocusing negatively, the power density inside the material is higher than on the surface, leading to stronger melting and vaporization, and allows the light energy to be transmitted deeper into the material. Therefore, in practical applications, negative defocusing is used when a greater fusion depth is required; positive defocusing is appropriate when welding thin materials.

(5)Gradual rise and fall control of laser power at welding start and end points

During deep penetration laser welding, the porosity issue always exists, regardless of the depth of the weld seam. When the welding process is terminated and the power switch is turned off, a depression will appear at the tail end of the weld seam.Additionally, when the laser welding layer covers the original weld seam, there can be excessive absorption of the laser beam, leading to overheating of the weldment or the formation of gas pores.To prevent the aforementioned issues, a program can be established for the power start and stop points, making the start and stop times adjustable. That is, the starting power electronically ramps up from zero to the set power value within a short period, and the welding time is adjusted. Finally, when the welding ends, the power gradually diminishes from the set power to zero.

1.2 Connector performance test

According to relevant standards, tensile-shear tests, fatigue performance tests, and analyses of the microstructure of the joint were conducted on the laser welded joints of the stainless steel car body.In summary, the relationship between the strength, appearance, and seam shape of the stainless steel laser-welded joint and the parameters of the laser welding process was established. This provides a basis for guiding production.The test results show that for the same plate thickness combination, the fatigue performance, shear tensile load, and appearance quality of the laser welded joints of stainless steel plates are all superior to those of resistance spot welded joints.

1.3 Numerical simulation research

Finite element calculation software is used to simulate the shape of the molten pool of the laser welded joint. This results in the micro shape of the joint under different combinations of process parameters, thereby obtaining the microscopic dimensions of the weld seam and judging the strength of the weld seam.Through verification, the mathematical model has high accuracy. In production, technological parameters can be determined through numerical calculation, reducing the number of tests and lowering the consumption of manpower and material resources.

1.4 Basic form of joint

The basic form of joints in the test is shown in Table 1.

Table 1 Basic forms of joints

| number | Joint form | Connector diagram | Plate thickness range/mm |

| 1 | Butt joint |  |

t ≤4 |

| 2 | lap joint |  |

t1+ t2 ≤6 |

| 3 | T-joint |  |

t1 ≥1 |

1.5 process assessment

According to relevant standards, through theoretical exploration of process parameters and verification through process and physical chemistry metallographic tests, a process evaluation and report are formed, providing a theoretical basis for guiding actual production.

Laser welding seam quality inspection and analysis

In terms of quality inspection and control, it is especially important to control the quality of the entire production process of laser welding, because some laser welding seams are non-penetrating laser welds.Before the welding operation production, it is necessary to verify the laser welding workpiece and validate the stability of parameters such as laser welding equipment power and welding speed. During the welding production process, strict assembly should be carried out according to the process method. In addition to ensuring that the welding seam surfaces fit closely together, it is also necessary to monitor the welding quality in real time during the welding process.By using direct or indirect technical means, it is necessary to analyse and confirm whether the molten depth of laser welding meets the quality requirements, and the records stored are traceable. At the same time, it has the functions of alarm prompt or adjusting welding parameters through the equipment's own adaptive function to compensate.After the welding is completed, in addition to the necessary visual inspection of the welding seam, it is also necessary to use ultrasonic non-destructive testing technology to check the molten depth of the welding seam. Ultimately, this ensures whether the molten depth of the non-penetrating laser welding seam is within the controlled range, ensuring the full process control of welding quality.

Conclusion

In summary, the non-penetrating laser welding process can solve various welding deformations in the side-wall resistance welding process, improve welding quality, replace traditional resistance spot welding with laser welding, increase the strength of the welded joint, improve the exterior quality of the vehicle body, and enhance production efficiency.At the same time, the transformation of stainless steel rail vehicle production technology has increased our company's competitiveness in the same industry. The application of laser welding technology to rail vehicles not only improves the overall quality of rail passenger cars, but also enhances the international competitive advantage of Chinese-made rail passenger cars.