Laser Seam Tracker

Features

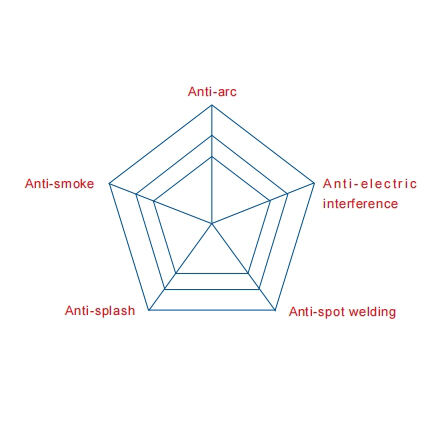

"Five anti" technology, perfect protection design, strong anti-interference

|

|

|

No IPC Required

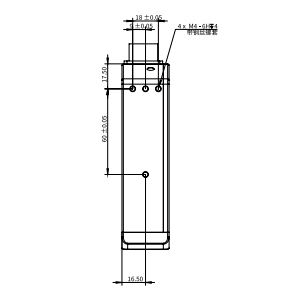

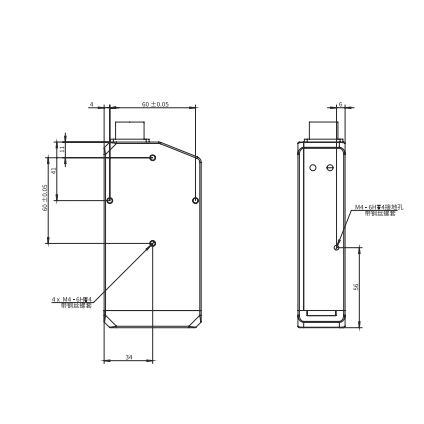

Built-in FPGA underlying algorithm processing, computing hard speed. Small size, low power consumption, suitable for a variety of installation

environments

Real-time Function

Efficient image algorithm to improve image processing speed.Unique tracking and calibration algorithm to ensure real-time tracking

Precise and Efficient

For a variety of welds, it can accurately identify and detect the position of the weld,reduce programming effort for complex workpieces

Diversification

Rich product line, suitable for different welding scenarios.Can adapt to different materials and welding processes.Support multiple brands of robot communication protocols

|

|

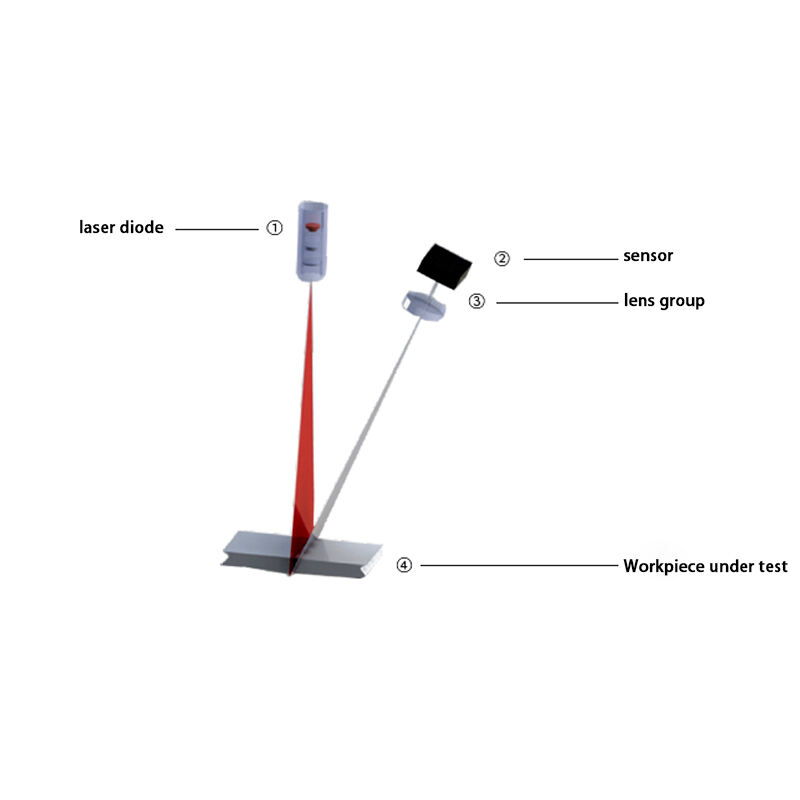

Principles

Using real-time welding seam tracking technology, non-contact tracking method, measuring welding seam offset, guiding welding torch positioning, avoiding welding defects caused by workpiece position deviation, and improving production efficiency and product quality

Solve Problems

Correct the welding seam deviation in real time and guide the welding torch to weld accurately;Effectively solve the problems caused by thermal deformation during the welding process.

Scope of Application

Communicate with various brands of PLC, text screen, IPC to realize connection and automatic control;Suitable for all kinds of welding machines such as straight seam special machine, circular seam special machine, welding trolley, gantry frame, cross special machine and so on.

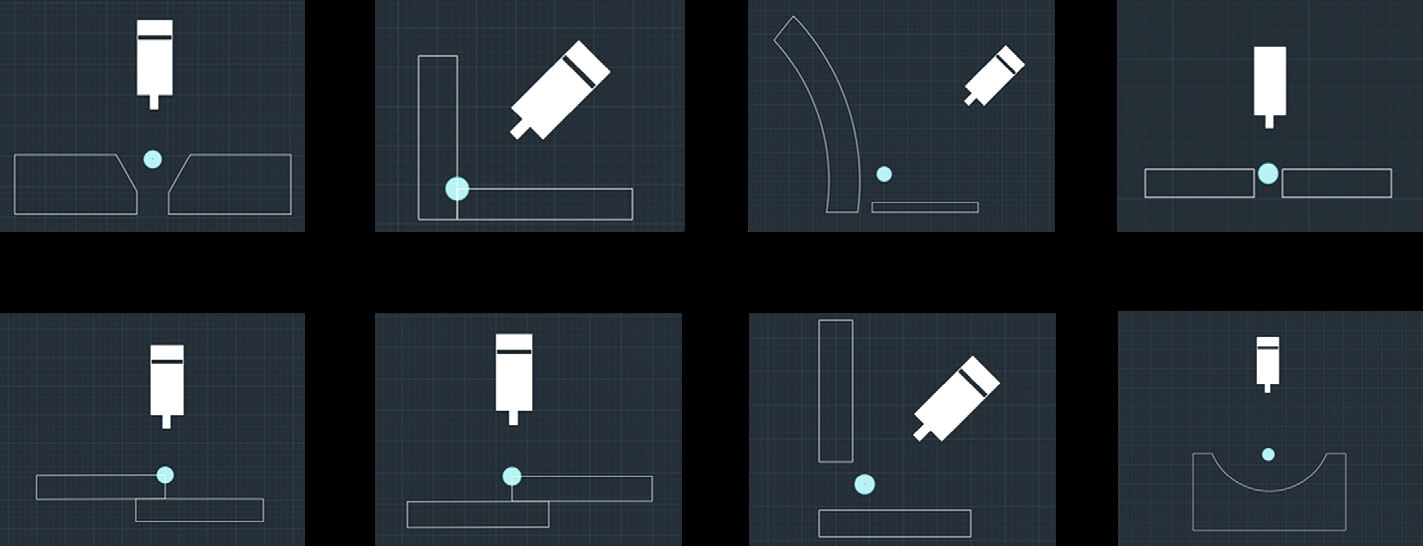

Weld Type

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR