DMK Laser Industrial 3D Ceramic Printers

Product Description

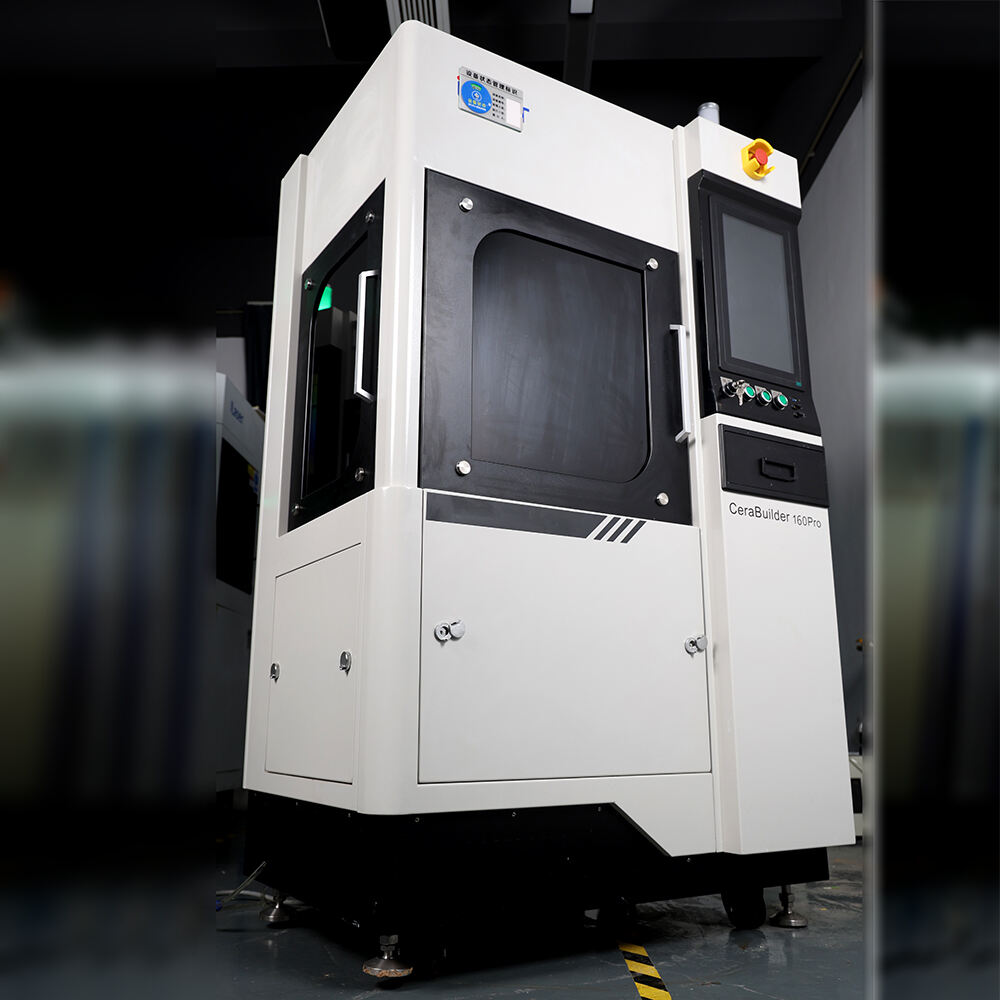

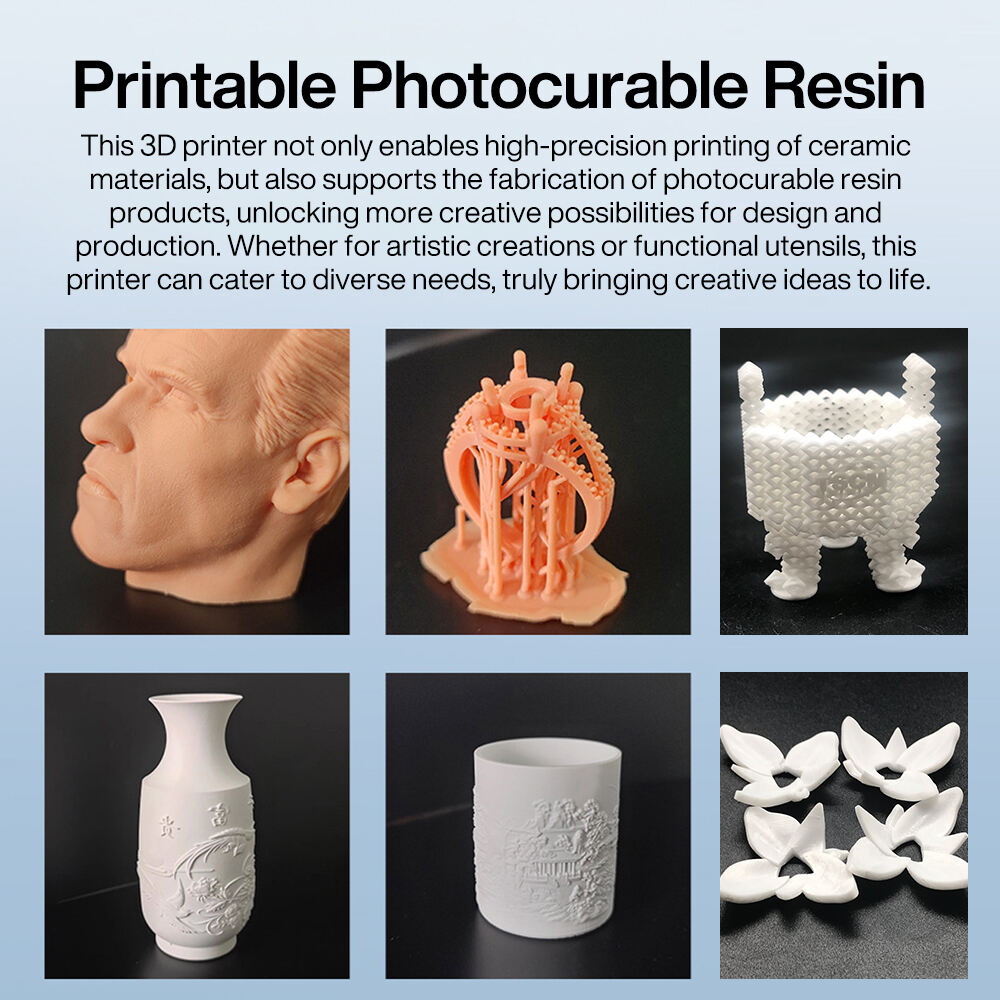

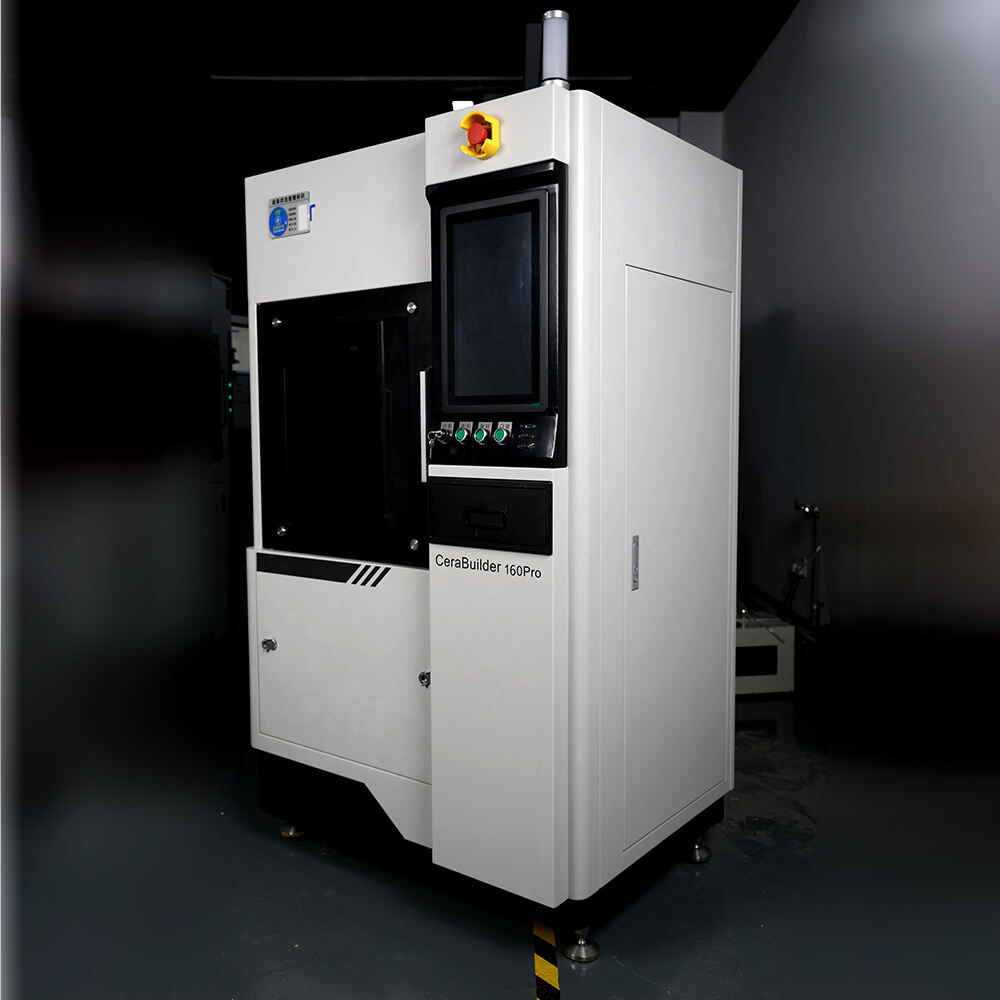

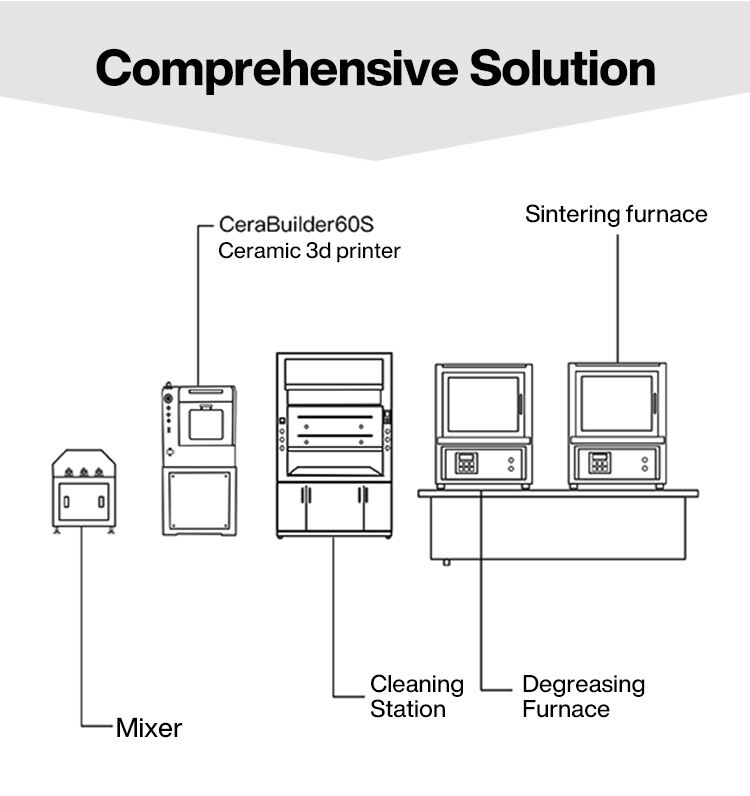

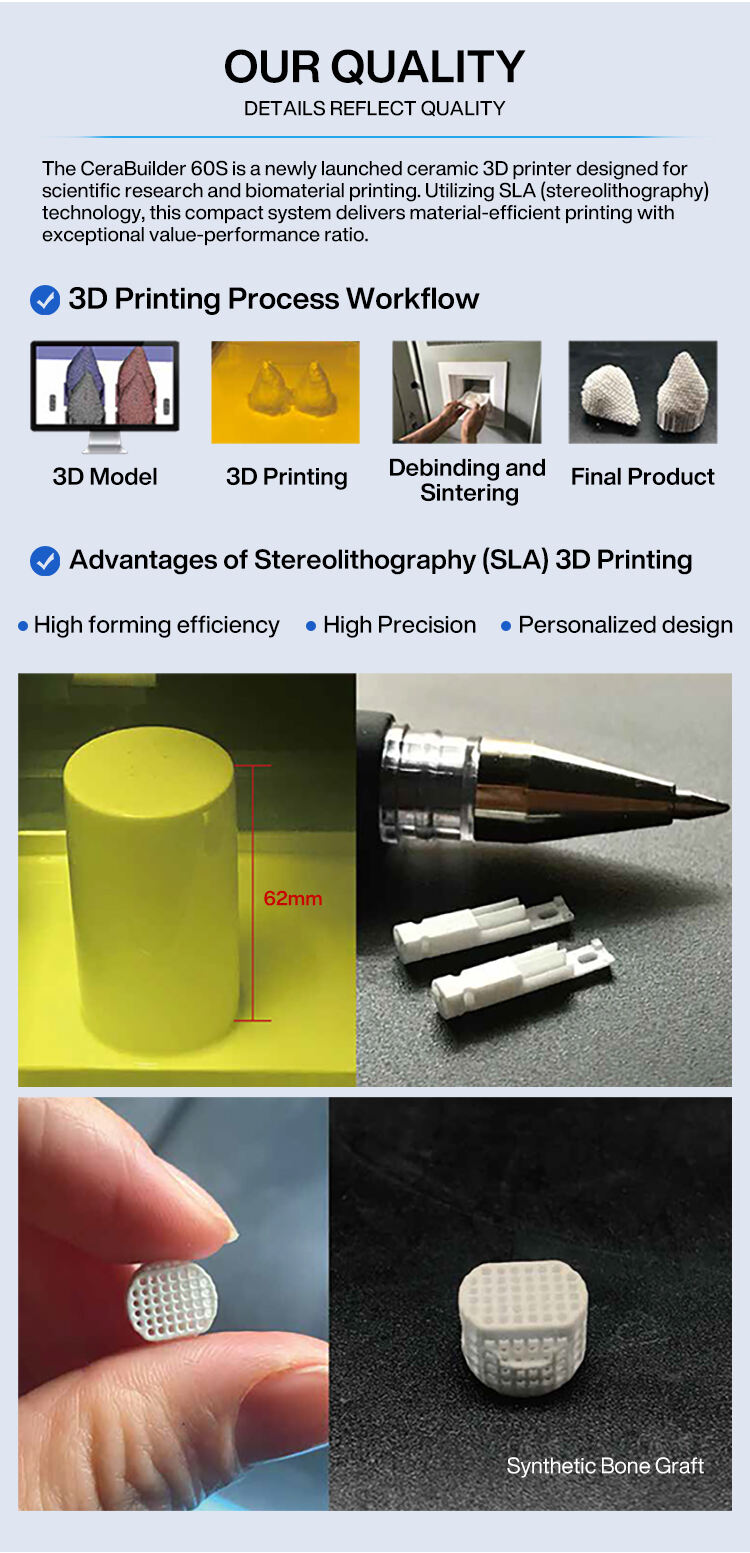

Our 3D Ceramic Printers, the CeraBuilder 60S and CeraBuilder 160Pro, offer top-tier performance for diverse applications. With precision ceramic printing capabilities, they are perfect for high-end manufacturing, medical, cultural, and small batch production needs.

|

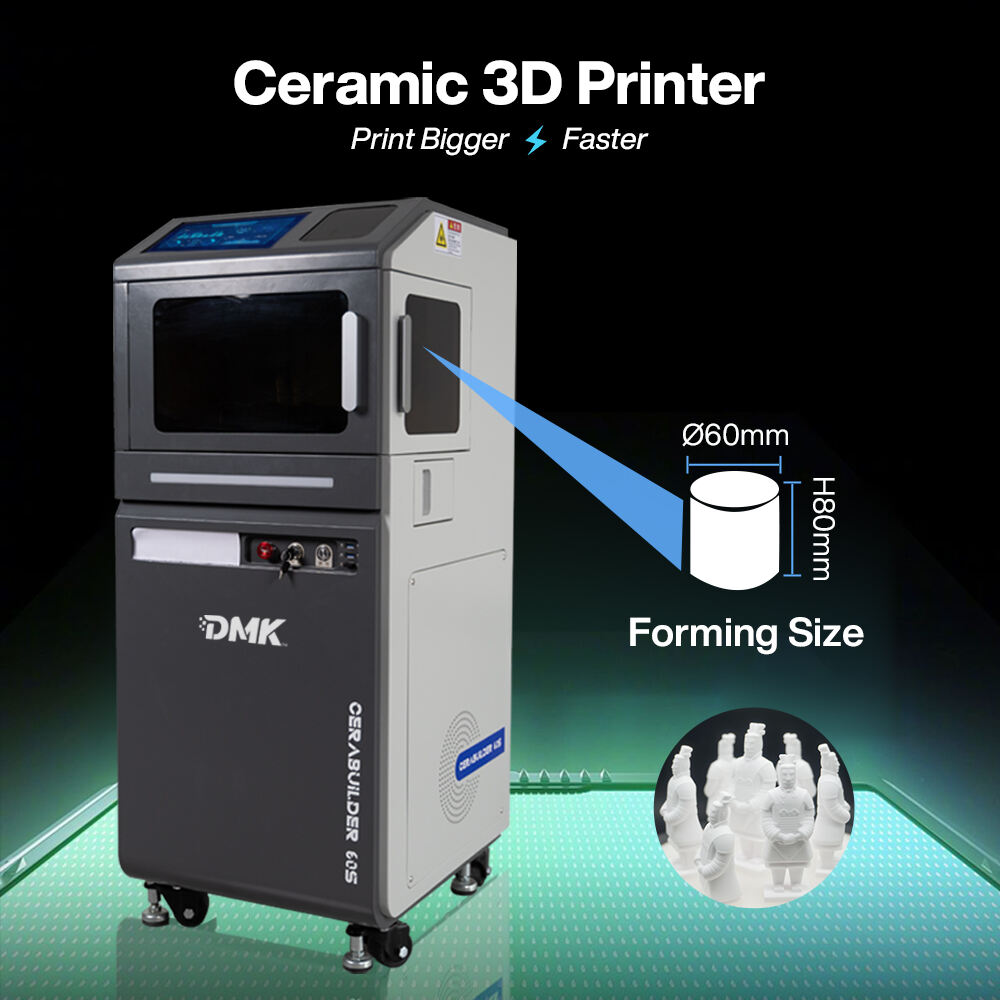

CeraBuilder 60S |

CeraBuilder 160Pro |

Key Features

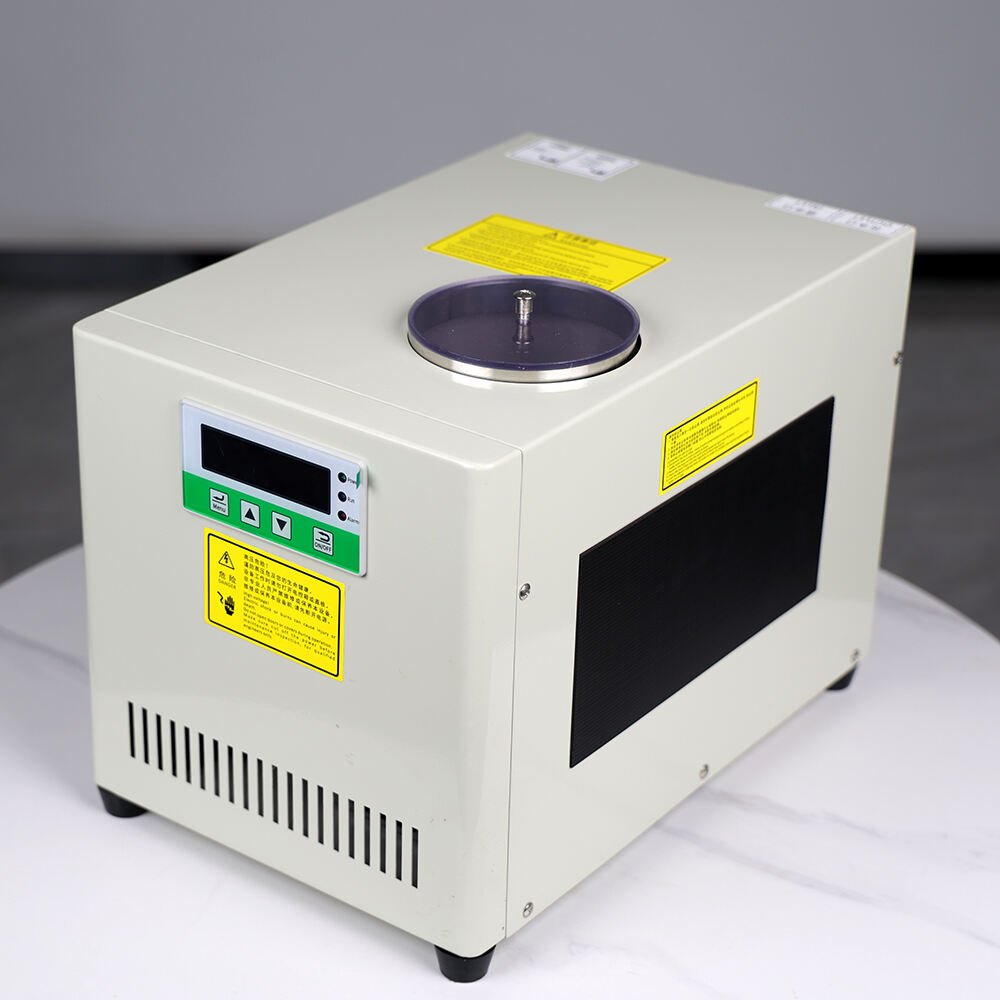

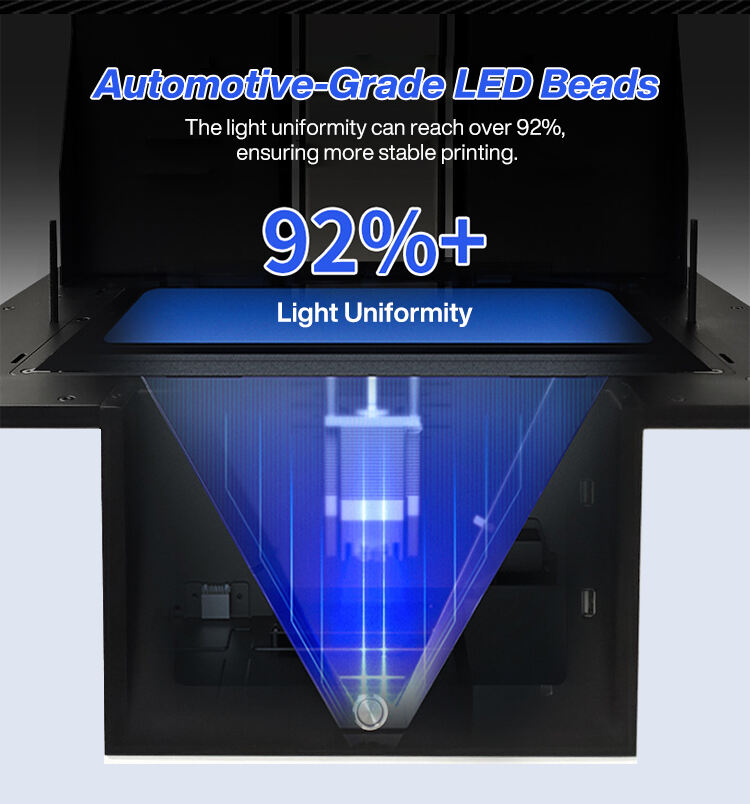

- Dual Wavelength Technology: Both models feature dual wavelengths of 355nm and 405nm (optional for the CeraBuilder 160Pro), ensuring high precision and quality in ceramic material processing.

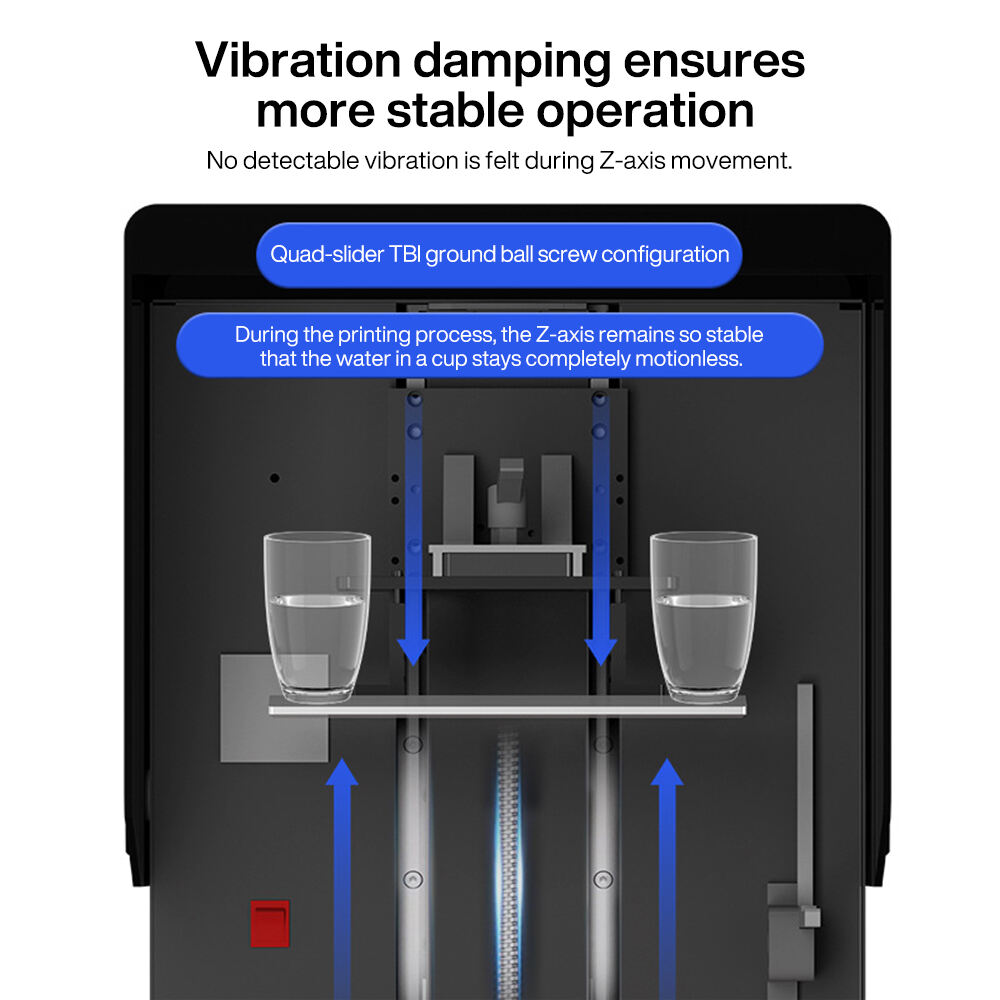

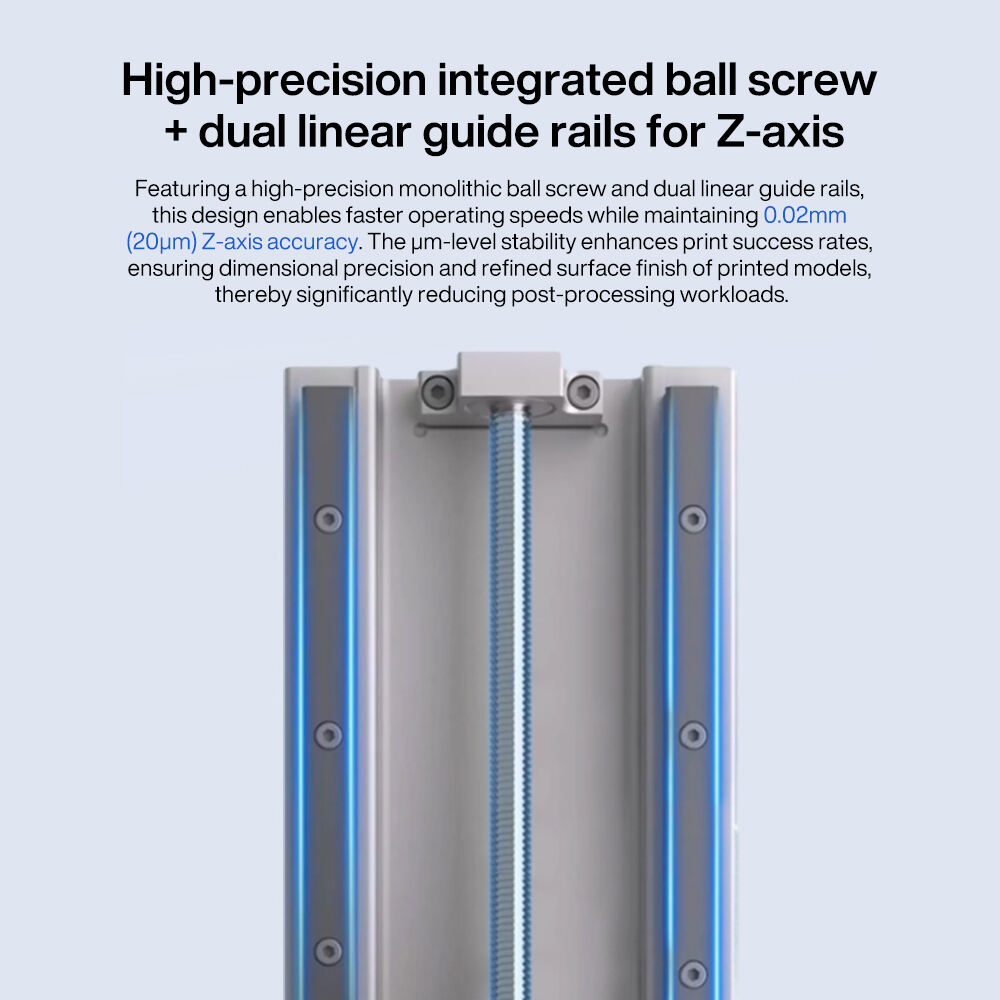

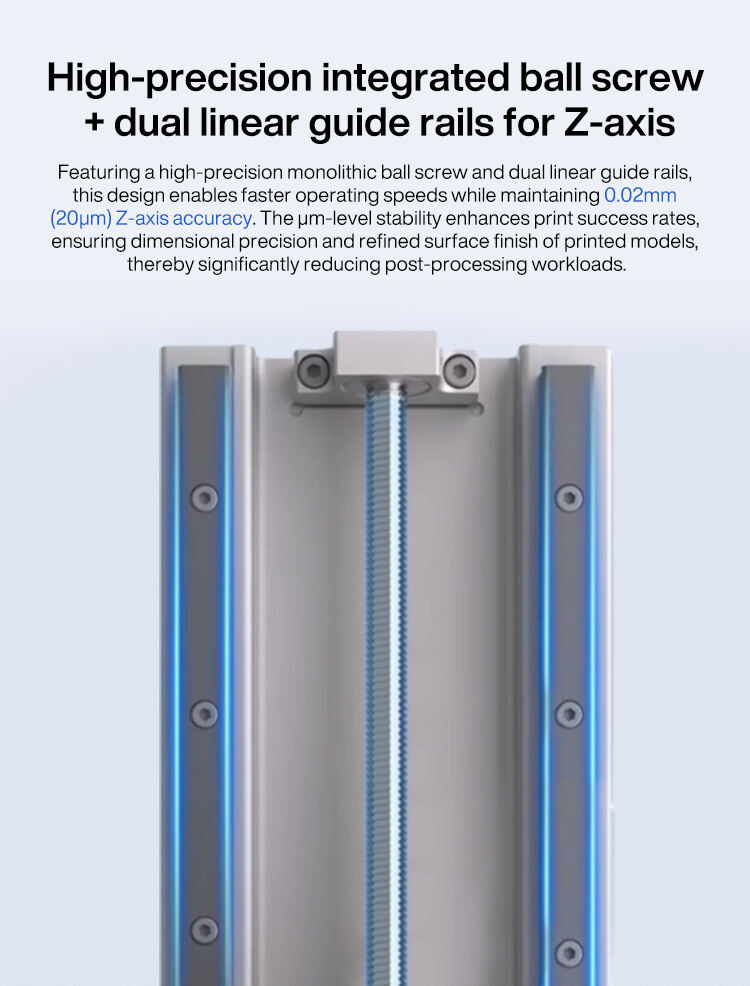

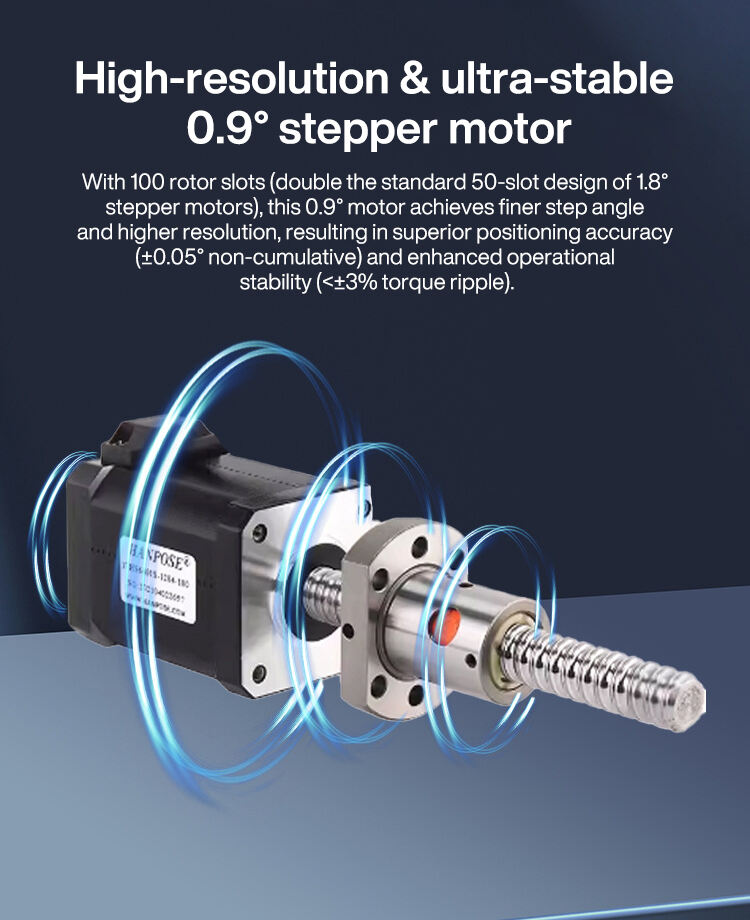

- Precision and Accuracy: Both models achieve a precision of ±0.05mm, with customized material options ensuring optimal results.

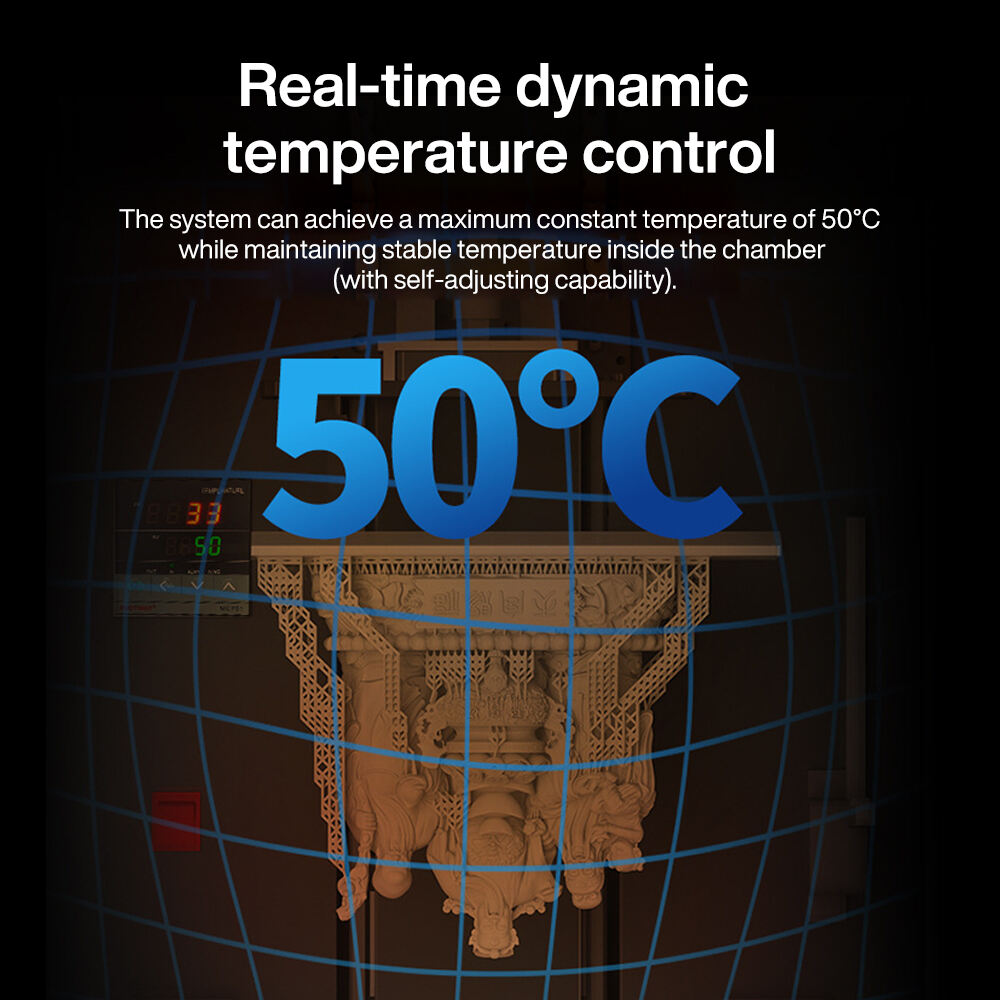

- Versatile Printing Capabilities: From 20 to 150 microns for layer thickness and up to 500 layers/hour for printing speed, these printers are designed for efficiency in high-demand environments.

Product Parameters

| Model | CeraBuilder 60S | CeraBuilder 160Pro |

| Printing Area | 60mm x 80mm | 160mm x 150mm |

| Laser Power | 400mW | 3W/5W |

| Precision | ±0.05mm (material dependent) | ±0.05mm (material dependent) |

| Printing Speed | ≤500 layers/hour | ≤400 layers/hour |

| External Dimensions | 530mm x 620mm x 1300mm | 1150mm x 900mm x 1750mm |

| Weight | ~140kg | ~750kg |

| Power Requirements | 220V/50Hz | 220V/50Hz |

| Max Machine Power | ≤1.5KW | 2.0KW |

Applications

- High-End Manufacturing: Ceramic cores, mufflers, ceramic nozzles, and more.

- Biomedical: Ceramic teeth, spinal fusion devices, prosthetics, and medical implants.

- Cultural Creations: Custom ceramic statues, Feng Shui items (like Pixiu), Guan Yin figures, vases, and intricate designs.

- Small Batch Production: Ceramic structural parts, lattice components, earrings, scaffolds, bushings, and electrode casings.

|

|

|

|

Materials & Customization:

Our printers are compatible with a wide range of ceramic materials, including:

- Silicon Nitride

- Glass Ceramics

- Metal Slag

- Silicon Carbide

- Silica

- Kaolin Clay

Additionally, we provide custom formulation services, including material recipe development, printing process optimization, and post-processing techniques.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR