- Hlavní strana

- Produkty

- O nás

- Videa

- Aplikace

- Novinky

- Pomocné centrum

- Kontaktujte nás

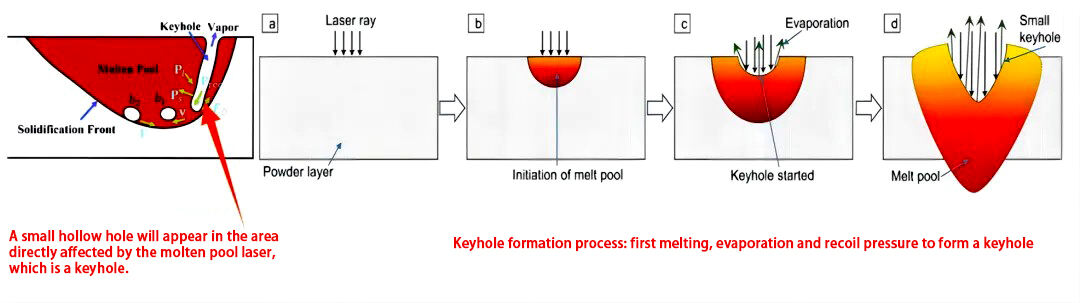

definice klíčové díry: Když je intenzita záření větší než 10^6W/cm^2, za působení laseru dojde k tavení a parování povrchu materiálu, a pokud je rychlost parování dostatečně velká, pak...

Kontaktujte nás

definice klíčové díry

Definice klíčové díry: Když je intenzita záření větší než 10^6W/cm^2, začne při působení laseru na povrch materiálu tát a parovat. Pokud je rychlost parování dostatečně velká, pak odrazový tlak vyvolaný párou je dost silný, aby překonal povrchové napětí tekutého kovu a jeho gravitaci, což nucí část tekutého kovu ustoupit. To způsobuje, že lavička v oblasti působení laseru propadá, tvoře malou jamku. Paprsek působí přímo na dno této malé jamky, což dále zapaluje a parní kov. Vysokotlaká pára pokračuje v tlačení tekutého kovu na dně jamky směrem k okrajům lavičky, čímž dále zhlubňuje díru. Pokud tento proces pokračuje, nakonec vznikne v tekutém kovu díra podobná klíčové díře.

Efekt klíčové díry v laserové svařování odkazuje na vznik malých bublin nebo děr kvůli tepelnému roztažení materiálu a odpařování vnitřních plynů během procesu laserového svařování. Tyto díry mohou ovlivnit kvalitu svařování a pevnost svárcového švu. Keyhole efekt nastává hlavně z následujících důvodů:

1) Tepelné roztažení materiálu: Vysoká hustota energie laserového paprsku rychle zvyšuje teplotu ve svařované oblasti, což způsobuje tepelné roztažení materiálu. To vedlo ke vzniku stresu a deformace ve svařované oblasti. Když není tepelné roztažení svařovaného materiálu rovnoměrné, je snadné vzniknout díram.

2) Vyparování vnitřních plynů: V svařovacím materiálu jsou malé množství plynů nebo nepůvodností. Když na svařovanou oblast dopadne laserový paprsek, vysoká teplota způsobí rychlé vyparování těchto plynů, čímž vznikají bubliny nebo díry. Tyto bubliny mohou bránit tvorbě svařovacího bazénu a zaplňování tekutého kovu, což ovlivňuje kvalitu svařování.

3) Chemické reakce materiálu: Vysoké teploty způsobují chemické reakce mezi svařovacím materiálem a kyslíkem, parou vody a dalšími prvkami přítomnými ve okolním prostředí, které vytvářejí oxidy nebo jiné sloučeniny. Tyto sloučeniny snižují teplotu tavení v svařované oblasti, zvyšují uvolňování plynů během procesu svařování a dále podporují tzv. klínový efekt.

Když tlak kovového páry vyvolaný laserovým paprskem v mikroporu dosáhne rovnováhy se povrchovým napětím a gravitací tekutého kovu, mikropora již nepokračuje v dalším zhlubování, čímž vzniká mikropora s ustálenou hloubkou. Toto je tzv. "keyhole effect" (effekt klíčové dírky).

2.Vytváření a rozvoj keyhole (klíčové dírky)

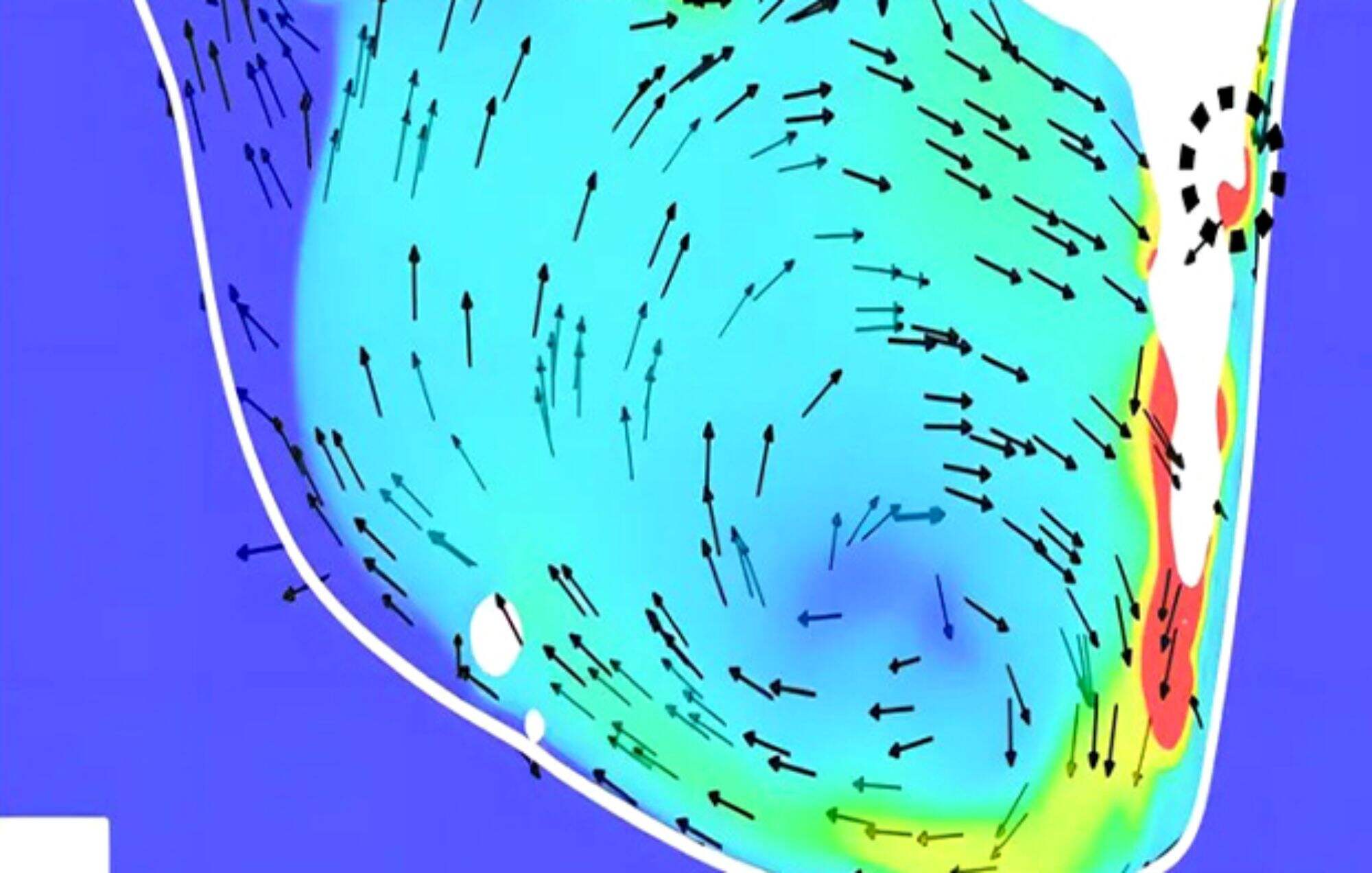

Během sváření je stěna keyhole (klíčové dírky) vždy v stavu vysoké nestability. Tenčí vrstva rozpouštěného kovu na přední stěně keyhole (klíčové dírky) tekou dolů spolu s oscilacemi stěny. Jakýkoli výstupek na přední stěně keyhole (klíčové dírky) bude silně parovat pod vlivem záření vysokohustotního laseru. Vzniklý pára je vystřelen dozadu, což ovlivňuje rozpouštěnou látku na zadní stěně, způsobuje oscilaci rozpouštěné lázně a ovlivňuje vylévání plynů z rozpouštěné lázně během procesu tuhnutí.

Díky přítomnosti mikropor proniká energie laserového paprsku do materiálu, čímž vzniká tento hluboký a úzký svařovací šev. Obrázek výše ukazuje typickou morfologii průřezu laserového hlubinného svařování. Hloubka svaření a hloubka klíčové díry jsou blízké (přesněji řečeno je metalografické srovnání 60-100 µm hlubší než klíčová díra, liší se vrstvou tekuté fáze). Čím vyšší je hustota laserové energie, tím hlubší je klíčová díra a tím větší je hloubka svaření. Při vysokopráhovém laserovém svařování může poměr hloubky ku šířce svařovacího švu dosahovat 12:1.

Nestabilita klíčové díry během procesu svařování je způsobena evaporací místního kovu na přední stěně klíčové díry. Faktory způsobující porozit jsou:

1) Místní evaporace způsobuje proniknutí ochranného plynu;

2) Spalování slitinových prvků;

3) Během laserového svařování hliníku a jeho slitin se rozpustnost vodíku v hliníku dramaticky snižuje během chladicího procesu.

3.Analýza absorpce laserové energie v klíčovém otvoru

Před vytvořením malé díry a plazmatu je energie laseru převáděna do vnitřku práce převážně tepelnou vodivostí. Svářecí proces patří k sváření vedením (do hloubky tavení 0,5 mm), a koeficient absorpce materiálu na laser je mezi 25-45%, jakmile je klíčový otvor vyformován, energie laseru je převáděna převážně díky efektu klíčového otvoru přímo do vnitřku práce. Svářecí proces se stává hlubinným svářením (více než 0,5mm hloubka tavení) , a koeficient absorpce může dosahovat 60~90% nebo více. Efekt klíčového otvoru sehrává extrémně důležitou roli při posilování absorpce laseru v procesech zpracování jako jsou laserové svařování , řezání a ražby. Laserový paprsek vstupující do klíčové díry je téměř úplně absorbován prostřednictvím více odrazů od stěny díry.

Obecně se předpokládá, že mechanismus absorpce laserové energie v klíčové díře zahrnuje dva procesy: inverzní bremsstrahlung absorpci a Fresnelovu absorpci.

3.1 Fresnelova absorpce

Fresnelova absorpce je mechanismus absorpce stěnou klíčové díry pro laser, který popisuje chování absorpce laseru při víceodrazech v klíčové díře. Když laser vstoupí do klíčové díry, na její vnitřní stěně dochází ke více odrazům a během každého odrazového procesu je část laserové energie absorbována stěnou klíčové díry.

Z levého grafu je vidět, že koeficient absorpce ocelí pro infračervené lasery je asi 2,5krát vyšší než u hořeče, 3,1krát vyšší než u hliníku a 36krát vyšší než u zlata, stříbra a mědi. U materiálů s vysokou odrazovostí jsou multiplikativní odrazy laserového paprsku v malé díře hlavním mechanismem absorpce energie v procesu hlubinného laserového svařování.

Nízká účinnost absorpce způsobuje nižší energetickou koupadelní efektivitu při laserovém svařování vysoko-odrazových materiálů (71 % vs. 97 %) a vyšší koncentraci absorpce energie na dně malé díry. Během procesu laserového svařování vysoko-odrazových materiálů, je rozdělení energie podél hloubky malé díry nesymetrické, což zrychluje nestabilitu díry a způsobuje poróznost, neúplné spojení a špatný vzhled.

3.2 Inverzní pevnostní absorpce

Dalším mechanismem absorpce v malé díře je plazmonická inverzní pevnostní radiace absorpce fotoindukovaná plazma neexistuje pouze nad východem malé díry, ale také naplní tuto díru. Laser se pohybuje v plazmě mezi dvěma odrazy od stěny díry, část jeho energie je absorbována plazmou a energie absorbovaná plazmou je předávána stěně díry konvekcí a zářením.

Role a podíl dvou mechanismů absorpce energie dva mechanismy absorpce laserové energie v malých dírách mají různý dopad na tvorbu spojové švy.

• Většina energie absorbované plazmou se uvolní v horní části malé díry a méně na dně, což usnadňuje získání díry tvaru „vínařského poháru“, ale není výhodné pro prodloužení hloubky díry.

• Energie uvolněná Fresnelovou absorpcí ze stěn díry je poměrně rovnoměrná ve směru hloubky díry, což je výhodné pro zvýšení hloubky díry a nakonec získání relativně hlubokého a úzkého spojového švu.

Z hlediska zlepšování kvality a efektivity svařování, pokud lze plazmu uvnitř malé díry ovládat tak, aby byla pro stabilitu svařování výhodnější, je laserová modulace, přizpůsobitelný okruhový režim a složený teplotní zdroj všechny potenciálně účinné technické řešení.

4.Tlaková rovnováha uvnitř klíčové díry

Během laserového hlubinného fúzního svařování se materiál dramatičně vaporizuje a rozpínací tlak vysokoteplotní páry odstrkuje tekuté kovy, čímž vzniká malá díra. Uvnitř této díry působí vedle párového tlaku materiálu a ablačního tlaku (také známého jako reakční síla parování nebo návratový tlak) také povrchové napětí, hydrostatický tlak způsobený gravitací a dynamický tlak vyvolaný prouděním roztaveného materiálu. Z těchto sil pomáhá udržet díru otevřenou pouze párový tlak, zatímco ostatní tři síly se snaží díru uzavřít. Aby bylo možné udržet stabilitu díry během procesu svařování, musí být párový tlak dostatečný na překonání ostatních odporových sil, aby došlo k ustálenému stavu a dlouhodobé stabilitě klínové díry. Pro jednoduchost se obecně předpokládá, že síly působící na stěnu klínu jsou především ablační tlak (recoilový tlak kovové páry) a povrchové napětí.

5. Nestabilita klíčové díry

Když laser působí na povrch materiálu, velké množství kovu parní, odrazová tlaková síla tlačí lávovou jámu dolů, čímž vzniká klíčová díra (keyhole) a plazma, která zvyšuje hloubku tavení. Během pohybového procesu, když laser narazí na přední stěnu klíčové díry, na všech místech, kde se laser dotýká materiálu, dochází ke zuřivému pálení materiálu. Zároveň dochází ke ztrátě hmotnosti na stěnách klíčové díry a odrazová tlaková síla vyvolaná pálením také tlačí tekutý kov dolů, což způsobuje, že se vnitřní stěna klíčové díry kolísá dolů, obejde spodní část klíčové díry a pohybuje se směrem k lávové jámě za klíčovou dírou. V důsledku kolísavého pohybu tekuté lávové jámy od přední stěny ke zadní stěně se neustále mění vnitřní objem klíčové díry a také se změní vnitřní tlak v klíčové díře. Měnící se tlak způsobuje změnu objemu emisivní plazmy. Změna objemu plazmy způsobuje změny v ochranném účinku, lomu a absorpci laserové energie, což způsobuje změny v množství laserové energie dosahující povrchu materiálu. Celý proces je dynamický a cyklický, nakonec vede k zubaté, vlnovité hloubce tavení kovu a není žádná hladce rovnoměrná hloubka svařovací šve.

Sekční pohled na střed spojové švy získaný po větvi řezu podél středu rovnoběžně se spojem, stejně jako graf změny hloubky klíčové díry měřené v reálném čase pomocí IPG-LDD, potvrzují toto tvrzení.

6. Periodické fluktuace klíčové díry

1. Laser působí na přední stěnu klíčové díry, což způsobuje prudkou parování přední stěny. Nárazový tlak tlačí na přední stěnu, tlačí tekuté kovy a urychluje jejich sestupné pohyby. Sestup tekuté kovy tlačí na kovový pára, který se vytrakuje z ústí klíčové díry. Náhle zvýšený kovový par absorbuje laserovou energii a ionizuje, současně refrakce a absorpce laserové energie způsobují ostré snížení laserové energie dosahující klíčové díry.

2. Ostře klesající množství laserové energie dosahující klíčové díry způsobuje snížení množství vaporizovaného kovu uvnitř klíčové díry. To způsobuje snížení tlaku v klíčové díře, množství kovového páru unikajícího z horního otvoru klíčové díry se snižuje a hloubka tavení se také snižuje.

3. S klesajícím množstvím kovového páru se snižuje ochrana, refrakce a absorpce laserové energie, což způsobuje, že více laserové energie dosahuje dovnitř klíčové díry a hloubka tavení se zvyšuje.

7. Klíčová díra potlačuje směr vlny

1) Povrchové napětí

Vliv: Povrchové napětí ovlivňuje proudění roztavené lázně;

Potlačení: Stabilizace procesu laserového svařování spočívá v udržování gradientní distribuce povrchového napětí v taveném bazénu bez excesivních fluktuací. Povrchové napětí je spojeno s teplotním rozložením, které je zase spojeno s teplotním zdrojem. Proto jsou kompozitní teplotní zdroje a oscilující svařování potenciálními technickými přístupy pro stabilizaci procesu svařování.

2) Tlak odrazu kovového plynu

Vliv: Tlak odrazu kovového plynu přímo ovlivňuje vznik klínových děr a je úzce spojen s jejich hloubkou a objemem. Navíc, jakože je kovový plyn jedinou látkou, která se během procesu svařování pohybuje nahoru, je úzce spojen s výskytem stříkání.

Inhibice: Vztah mezi párou kovu a objemem klíčové díry vyžaduje pozornost na plazmový efekt a velikost otvoru klíčové díry. Čím větší je otvor, tím větší je klíčová díra, čímž se kolísání v malém roztaveném bazénu dole zdají být zanedbatelná. To má menší vliv na celkový objem klíčové díry a změny vnitřního tlaku. Proto jsou laser s přizpůsobitelným prstencovým režimem (prstencovité skvrny), kombinace laseru a oblouku, frekvenční modulace atd. všechny potenciální směry pro rozvoj.