1. OverviewCurrently, the main types of lasers used in cutting applications are CO2 lasers and fiber lasers. A CO2 laser is generated by exciting CO2 gas under high frequency and high pressure, producing a laser with a wavelength of 10.6μm. The be...

Contact Us

1. Overview

Currently, the main types of lasers used in cutting applications are CO2 lasers and fiber lasers. A CO2 laser is generated by exciting CO2 gas under high frequency and high pressure, producing a laser with a wavelength of 10.6μm. The beam is directed and focused via resonator mirrors and copper reflectors to perform cutting.

Fiber lasers use multiple multimode pump diodes arranged in parallel as the laser source, generating a laser also at 10.6μm. The beam is then coupled into a single fiber through resonator tuning, resulting in a high-power laser.

2. Comparison of CO2 Laser Cutting and Fiber Laser Cutting Processes

(1) Laser Structure Comparison

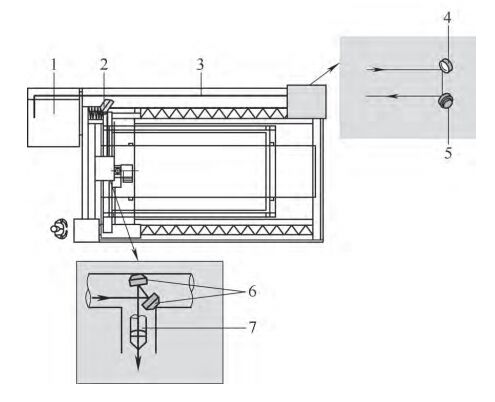

CO2 laser generators are large in size and use air as the transmission medium. The laser travels in a straight line via reflectors, which causes rapid beam attenuation and significant energy loss. The optical-electrical conversion efficiency is low, only about 10%, as shown in Figure 1.

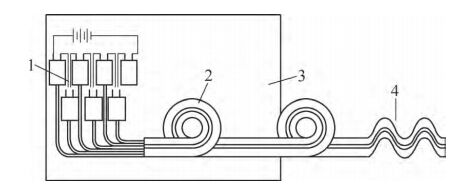

Fiber lasers use multiple sets of multimode pump diodes in parallel. The laser is transmitted through optical fibers, confined within the fiber, and travels in a "curved" path. This method is unaffected by the external environment and offers a high optical-electrical conversion efficiency—over 25%, as shown in Figure 2.

Figure 1 CO2 laser

1. laser generator 2. drive unit reflector 3. optical path 4, 5, 6. angular reflector 7. focusing lens

Figure 2 Fiber laser

1. laser source 2. resonant cavity 3. cooling system 4. optical path

(2) Cutting Materials Comparison

CO2 lasers can cut carbon steel, stainless steel, aluminum alloy, and non-metallic materials, but cannot cut copper. Copper is highly reflective to the 10.6μm wavelength and reflects most of the beam without absorbing it, which may cause damage to the laser source due to back-reflection.

Fiber lasers can cut carbon steel, stainless steel, aluminum alloy, and copper, but cannot cut non-metallic materials, such as wood, plastic, and leather. They also cannot cut materials with surface coatings like laminated stainless steel or rust-proof specialty steel plates.

(3) Cutting Performance Comparison

Cutting efficiency includes cutting speed, piercing performance, and edge quality, which are key indicators in evaluating laser cutting machines.

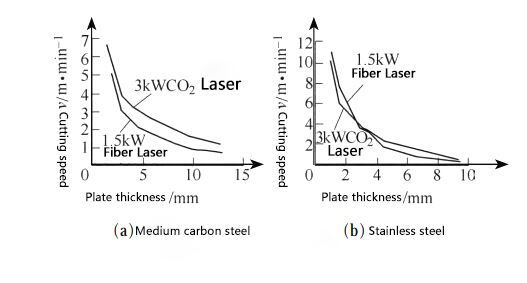

Fiber lasers excel in cutting thin sheets, especially those under 3mm thick, where they can be up to 4 times faster than CO2 lasers. At 6mm thickness, both lasers perform similarly, marking the threshold where their advantages shift. For materials thicker than 6mm, CO2 lasers begin to show an advantage, although the difference is not drastic. (See Figure 3 for cutting speeds on various materials.)

Before cutting starts, the laser must first pierce the material. Fiber lasers generally have longer piercing times compared to CO2 lasers. For example, with a 3kW laser cutting 8mm carbon steel, a CO2 laser is about 1 second faster per hole, and 2 seconds faster for 10mm. Over 2000 piercings per day, this results in a time difference of 6000 seconds, or about 1.7 hours per day.

Edge quality is usually evaluated based on roughness and verticality. For steel plates under 3mm, fiber laser cuts have slightly poorer edge quality than CO2 laser cuts. As thickness increases, the difference becomes more noticeable. For stainless steel plates 3mm or thicker, fiber laser edges appear matte, while CO2 cuts are shiny. For 16mm carbon steel, fiber laser edge verticality ranges from 0.4–0.5mm, while CO2 achieves 0.1mm.

Moreover, due to the low frequency and high energy density of fiber lasers, cutting small holes in carbon steel may cause overheating.

A summary comparison of CO2 and fiber laser cutting processes is provided in Table 1.

Figure 3 Cutting speed of different materials

Table 1 Comparison of basic process parameters between CO2 laser and fiber laser cutting

| Item | CO₂ Laser | Fiber Laser |

|---|---|---|

| Laser Type | Complex | Simple |

| Laser Wavelength (μm) | 10.6 | 1.06 |

| Photoelectric Conversion (%) | 10 | ≥25 |

| Applicable Materials | Carbon steel, stainless steel, aluminum alloy, non-metal materials | Carbon steel, stainless steel, aluminum alloy, copper materials |

| Cutting Speed | relatively soon | Very fast for plates under 3mm, similar to CO2 laser for plates over 6mm. |

| Perforation Capability | Better than fiber laser | Slightly inferior to CO₂ laser |

| Cutting Surface Quality | Better than fiber laser | Plates below 3mm are slightly worse than CO2 laser, the greater the plate thickness, the more obvious the difference in cross-section quality. |

Table 2: Cost Analysis of CO₂ Laser vs. Fiber Laser Cutting

| Form | Consumption | ||

| CO2 Laser | Fiber laser | ||

| Laser generating gas consumption |

He(99.999%)/L∙h-1

|

13 | - |

|

N2(99.999%)/L∙h-1

|

6 | - | |

|

CO2(99.999%)/L∙h-1

|

1 | - | |

| Compressed air/Nm3∙h-1 | - | 35 | |

| Cutting gas consumption | Cutting speed/m∙min-1 | 2.5 | 8.2 |

|

N2(99.99%)/Nm3∙h-1

|

20.27 | 39.35 | |

| Electricity consumption | Total equipment power/kW | 47.56 | 28.56 |

| Depreciation of equipment | Total Purchase and Installation Cost / CNY·year⁻¹ | 650,000 | 700000 |

| Equipment Maintenance | Routine Maintenance Cost / CNY·year⁻¹ | 100000 | 70000 |

| Consumable and expendable items consumption |

Focusing lens / piece ∙ year⁻¹ | Approx. 4 | - |

| Protective lens / day ∙ piece⁻¹ | - | 2.5 | |

| Nozzle / hour ∙ piece⁻¹ | 40 | 40 | |

|

Other consumables / yuan ∙ year⁻¹ (Filtering elements, magnetic rings, cooling water) |

Approximately 4000 | Approximately 4000 | |

Note: Labor cost, management cost, and profit factors are not considered in the above cost analysis.

3. Cost Analysis of CO2 vs. Fiber Laser Cutting

Taking 5mm stainless steel plate cutting as an example, a cost comparison is shown in Table 2.

Based on the table and assuming 3860 working hours per year:

CO2 laser cutting: Operating cost = ¥268.8/hour

Fiber laser cutting: Operating cost = ¥242.7/hour

With cutting speeds of 2.5 m/min (CO2) and 8.2 m/min (fiber):

CO2 cost per meter = ¥1.79

Fiber laser cost per meter = ¥0.48

4. Summary and Recommendations

Both CO2 and fiber laser cutting technologies have their own suitable applications.

CO2 lasers can cut carbon steel, stainless steel, and aluminum alloy, as well as semiconductors, non-metals, and composite materials, giving them a wider application range.

Fiber lasers can cut carbon steel, stainless steel, aluminum alloy, and copper—which CO2 lasers cannot—but they cannot cut non-metal materials.

In terms of cutting cost, fiber lasers are significantly more economical than CO2 lasers.

Recommendations for laser selection:

For materials ≤ 4mm thick: Choose fiber lasers for their higher speed and efficiency—better overall value.

For materials ≥ 8mm thick: Choose CO2 lasers for better piercing performance and edge quality—especially when fiber lasers no longer offer a clear speed advantage.

For copper or mirror-finished stainless steel: Choose fiber lasers.

For semiconductors, non-metals, or composite materials: Choose CO2 lasers.