- Pagina Iniziale

- Prodotti

- Chi Siamo

- Video

- Applicazione

- Notizie

- Centro Assistenza

- Contattaci

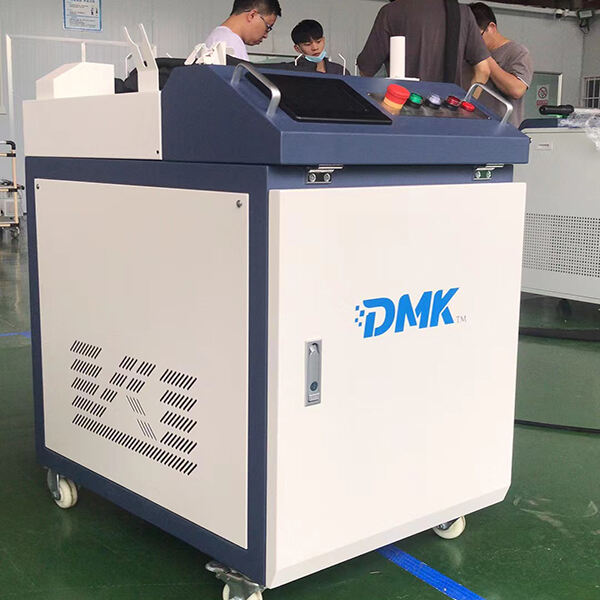

Vi siete mai chiesti come alcuni oggetti ordinari sono pensati per essere perfetti? La risposta dipende dall'uso di tecnologie come Dmk macchine per rimozione della ruggine laser portatili . hai mai sentito parlare della macchina di saldatura a stella laser? questo è davvero uno strumento utilizzato per collegare più fusione due elementi relativi al metallo insieme. esploreremo i grandi vantaggi, innovazione, sicurezza, utilizzo, utilizzo, fornitore, qualità, più applicazione di macchine di saldatura a stella laser.

Alcuni vantaggi molto belli di utilizzare un Dmk pulizia laser della ruggine la macchina richiede un tempo di lavoro inferiore per saldare due metalli insieme rispetto all'apparecchio di saldatura convenzionale. Inoltre aiuta a garantire che i metalli non siano feriti durante la saldatura riducendo al minimo le temperature della zona colpita.

La macchina di saldatura laser star ha avuto una quantità totale complessiva che è grande all'interno del business di saldatura. applicando questa tecnologia, è ora più facile fissare piccole sezioni come gioielli preziosi, prodotti medici, più metallo che è stato minuscolo con una maggiore precisione. inoltre più sicuro e semplice da utilizzare Dmk macchine per la pulizia della ruggine .

La protezione è davvero un problema che è stato top lavorando insieme con qualsiasi dispositivo di saldatura. Dmk macchina per rimozione della ruggine laser a mano la macchina emette meglio il raggio laser, che è meno dannoso rispetto all'hardware di saldatura convenzionale. Inoltre riduce la possibilità di esplosione come incendio, rendendola più sicura da utilizzare.

La macchina di saldatura laser star può essere utilizzata per saldare metalli, difficili come morbidi, insieme. è adatto al metallo che è collegamento era diverso come titanio, argento, rame, argento, più metallo. Dmk rimozione laser della ruggine è vantaggioso per molte applicazioni quali, ad esempio, la fissazione di gioielli preziosi, la fissazione di dispositivi dentali, la fissazione di occhiali e la produzione commerciale.

Adottiamo costantemente i valori fondamentali di "centrato sul cliente" e "creare valore soddisfacente per il cliente". Consideriamo le esigenze dei clienti come la principale preoccupazione nelle nostre scelte prioritarie. Partecipiamo sinceramente all'iniziativa "Made in China 2025" e utilizziamo tecnologie e servizi per contribuire a far crescere i mercati del laser in modo intelligente. Spinti dalla doppia forza di Internet+ e Industria 4.0, rispondiamo strettamente alle esigenze dell'era industriale di Internet. Forniamo la fondamentale macchina per saldatura laser Star al fine di offrire servizi applicativi in grado di individuare e collaborare con i nostri partner per raggiungere una maggiore efficienza, uno sviluppo più rapido e veloce.

DMK si trova all'interno della East Lake High-tech Development Zone (Optics Valley) situata a Wuhan, in Cina. Siamo l'azienda che punta sull'alta tecnologia specializzandosi nello sviluppo, ricerca, produzione e fornitura di apparecchiature laser complete. Nella squadra del nostro fondatore si contano poche decine di ricercatori. Sulla base del sistema laser come la macchina per saldatura Laser Star e con un ampio dipartimento post-vendita, siamo in grado di fornire soluzioni personalizzate per attrezzature di lavorazione al laser automatizzate destinate a clienti internazionali e nazionali. Offriamo inoltre un'assistenza professionale post-vendita per aiutare gli utenti a risolvere rapidamente eventuali problemi urgenti relativi ai loro prodotti o servizi.

Con il costante sviluppo della tecnologia laser a fibra, abbiamo effettivamente incorporato laser che provano di livello mondiale e la tecnologia. collaboriamo con la macchina di saldatura laser stella che è nazionale e società di sistema di controllo come ad esempio Raycus Max, JPT amichevolezza Raytools Sup qilin estun. dal punto di vista professionale dei

La nostra azienda attualmente comprende una catena di fornitura che comprende otto principali tipi di beni e carichi di articoli, come ad esempio per esempio macchine che sono complete possono essere utilizzate per il taglio laser, saldatura laser e pulizia laser, in scelta per attrezzature come {parola chiave} oltre alle teste laser. I nostri articoli

L'apprendimento dell'uso della macchina di saldatura a stella laser non è complicato. Dmk laser di pulizia della ruggine infine, utilizzare il pedale del piede per innescare la macchina, insieme con la procedura di saldatura deve iniziare.

La ricerca di un fornitore per qualsiasi macchina è semplice. Le organizzazioni di produzione creano manuali per i fornitori che ti guidano sul modo migliore di prenderti cura della macchina, come la pulizia regolare, il controllo di ogni danno quando guardi la macchina Dmk laser di pulizia della ruggine , oltre a sostituire le migliori sezioni che non funzionano correttamente. le imprese offrono inoltre corsi su come utilizzare meglio la macchina, che sarà necessario per i principianti.

La qualità è infatti un'opzione che sono importanti investimenti in una macchina di saldatura a stella laser. quando l'acquisto, considerare aspetti quali ad esempio la durata, l'efficacia, più precisione. Dmk laser di pulizia della ruggine che sarà grande, resistente e con sezioni che non si rompono o si danneggiano facilmente. Dovrebbe essere efficiente, il che significa che funzionerà bene per molte applicazioni. Infine, deve essere preciso, garantendo un saldatura che sia ottimale.