Robotic Laser Cladding System

Product Description

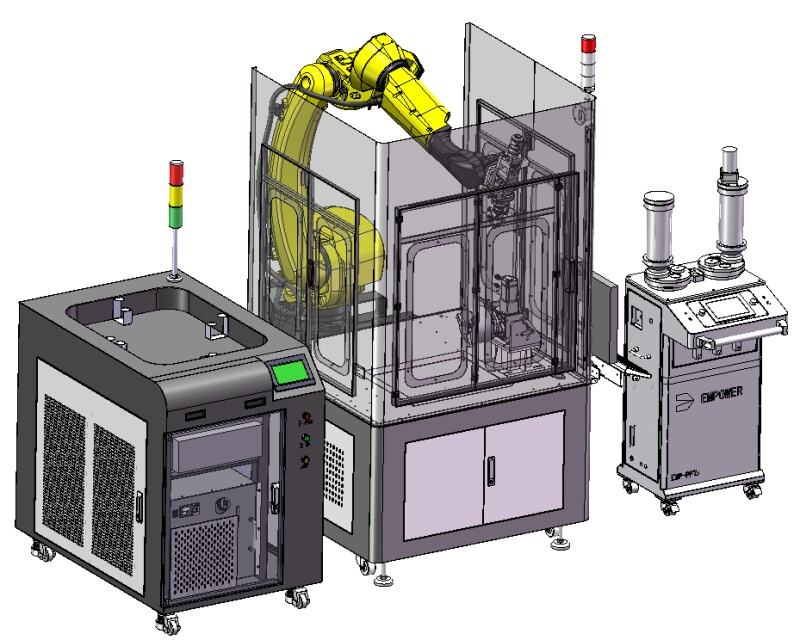

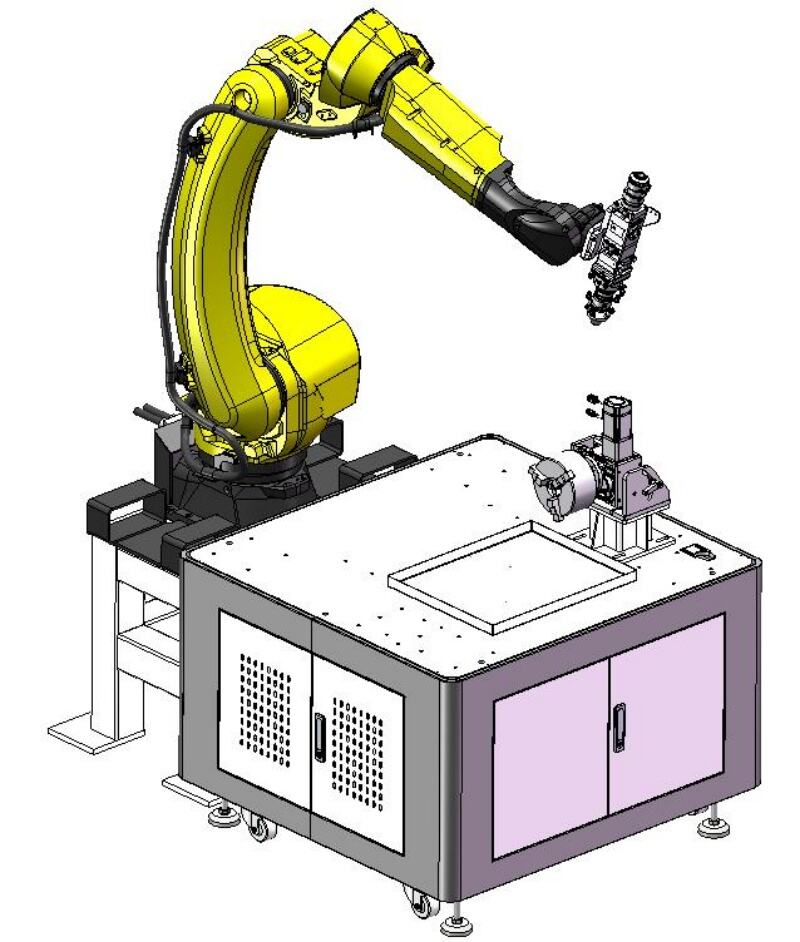

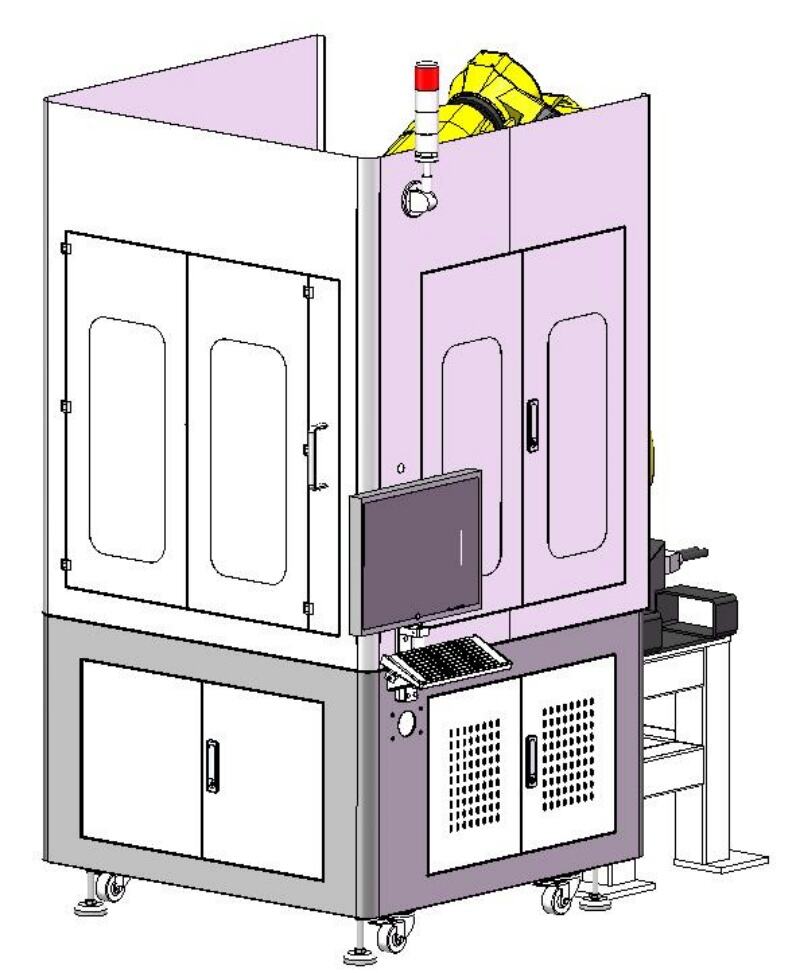

The whole processing system includes double-barrel powder feeder, workbench components, industrial robots, laser heads, chillers, lasers, etc. The laser head movement actuator adopts industrial robots, and the bracket part on the equipment adopts a semi-open form to facilitate the movement of the robot. The workpiece is clamped on the rotary table. Chillers and lasers are installed in sheet metal cabinets.

Specifications

| Serial number | Name | Manufacturers | Specification Model | Main parameters | Quantity |

| 1 | Fiber Laser | MAX | MFSC-3000X | 1. Fiber laser with 3000w output power; | 1 |

| 2. Power adjustment range: 10-100%; | |||||

| 3. Wavelength 1080 (±10nm); | |||||

| ▲4. Fiber core diameter 600μm, length 20m, interface LOE; | |||||

| 5. Short-time power stability (100% continuous > 1h): ±2% (maximum); | |||||

| 6、Long-time power stability (100% continuous > 24h): ±5% (maximum); | |||||

| 7. Input voltage: 380v; | |||||

| 8. Maximum power consumption: 10KW; | |||||

| 9, minimum fiber optic cable bending radius: 200mm; | |||||

| 2 | Laser head | RAYTOOLS | BC104 | 1、Fiber optic interface: LOE; | 1 |

| 2. Withstand power: 4kw; | |||||

| 3、Collimation 100mm, focusing focal length 250mm; | |||||

| 4. Projection wavelength: 1080nm; | |||||

| 5、Collimation focusing range: 0-20mm; | |||||

| 6、Configuration of coaxial powder feeding nozzle, powder convergence size: ≤2.5mm. | |||||

| 3 | Control System | DMK | V1.0, Chinese - no upper computer, XW100 | 1、Control system with independent intellectual property rights, supporting EtherCAT bus/impulse servo control; | 1 |

| 2、Three axes teaching (XYZ linear), XY plane teaching; support import graphics processing; PSO process adjustment, power curve process control; | |||||

| ▲3. Support 3+N axes movement, strong expandability, can add no less than 90 NC axes movement/infinite expansion IO; | |||||

| 4. realizing the integrated control of the laser, the chiller, the motion mechanism and the gas circuit unit; | |||||

| ▲5. The operation interface is customized by customers; | |||||

| ▲6. The program can be imported to realize 3D printing work. | |||||

| 4 | Water Chillers | HANLI | RMFL-3000ANT | ▲1、Power supply voltage 220V,rated power 2.71kw; | 1 |

| 2、Refrigerant: R-410a. | |||||

| 3. Temperature control accuracy: ±0.5°C; | |||||

| 4、Pump power: 0.4kw; | |||||

| 5. Water tank capacity: 16L; | |||||

| 6、Maximum head of the pump: 40m; | |||||

| 7、Rated flow rate: 2L/min+>18L/min. | |||||

| 8、Net weight 59kg,gross weight 71kg; | |||||

| 9. Size (length, width and height): 88*48*43cm; | |||||

| 10、Includes custom chiller sheet metal cabinet. | |||||

| 5 | Double cylinder powder feeder | DMK | EMP-PF-2-1 | 1. Input:220VAC,50HZ; | |

| 2、Power:≤1kw; | |||||

| 3、Can send powder size: 20-200μ; | |||||

| 4、Speed of powder feeding disk:0-20rpm stepless speed adjustment; | |||||

| 5、Repeat accuracy of powder feeding:<±2%; | |||||

| 6, the required gas source: nitrogen/argon gas; | |||||

| 7、Control mode:PLCindependent controllable | |||||

| 8、Outline size:630mm*500mm*1550mm(length, width and height) | |||||

| 6 | Industrial robots | ESTUN | M-20iD | 1、Load: 25.0Kg; | 1 |

| 2. Number of controllable axes:6; | |||||

| 3. Reachable radius:1831mm; | |||||

| 4、Repeat positioning accuracy: ±0.02mm; | |||||

| 5、Robot weight: 250Kg. | |||||

| 7 | Workbench components | DMK | Customized | Includes work cabinet, robot mounting base, chiller sheet metal cabinet, rotating platform, etc. | |

| Generator Accessories | DMK | Customized | Contains 10 pieces of protective lenses, 3 pairs of protective glasses; gas, water and electric circuits, etc. |

-

Robotic Laser Cladding System

-

Robotic Laser Cladding System

-

Robotic Laser Cladding System

Quick Detail

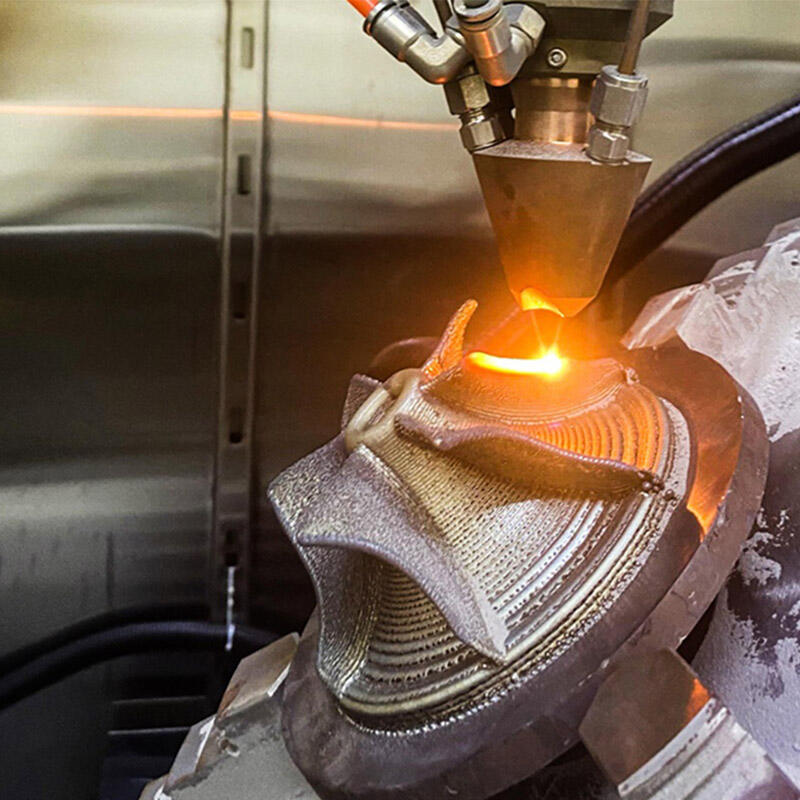

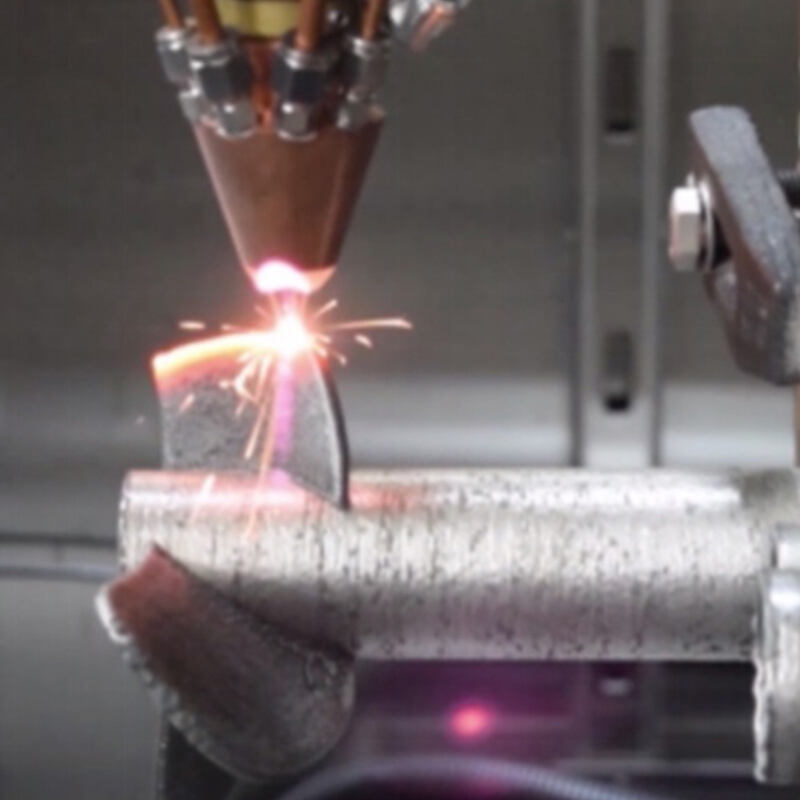

For example, the equipment motion system is composed of two parts, which are robot motion mechanism and rotating platform mechanism. The workpiece is clamped on the rotating platform, and the laser head is mounted on the industrial robot, which can realize the laser to fuse the workpiece at different angles.

The working platform is made of welded square and sheet-metal wrapped edge, which is strong and firm with beautiful appearance. The upper part of the cabinet has observation windows on three sides for easy observation of the internal processing. The workbench is equipped with display screen, keyboard, tricolor light, etc.

Applications

Industrial robot automated laser cladding equipment is mainly used for surface coating and repair, and can be widely used in the following fields:

Automobile manufacturing: In the automobile manufacturing process, laser cladding equipment can be used to repair the worn or damaged surfaces of high-value components such as engine parts, shock absorbers, and turbine blades, and improve the life and performance of parts.

Aerospace: The aerospace field places extremely high demands on the performance and quality of materials. Laser cladding equipment can be used to repair aeroengine blades, turbine disks, aerospace structural parts, etc., to improve their wear resistance and corrosion resistance.

Railway transportation: In the field of railway transportation, laser cladding equipment can be used to repair and strengthen the surface of rails and key components of railway vehicles, improving their service life and safety.

Power industry: In the power industry, laser cladding equipment can be used to repair and strengthen blades, turbines, bearings and other components of power generation equipment to improve their work efficiency and reliability.

Petrochemical: Laser cladding equipment can be used to repair and protect valves, pipes, pump casings, etc. of petrochemical equipment, providing higher wear and corrosion resistance in harsh working environments.

Metal processing: Laser cladding equipment can be used to repair and strengthen the surface of metal molds, tools and parts, improving their service life and accuracy.

Competitive Advantage

Industrial robot automated laser cladding equipment has the following advantages:

High precision and controllability: Laser cladding equipment can achieve very precise cladding operations. By controlling parameters such as laser power, scanning speed and path, the thickness and shape of the cladding layer can be precisely controlled to achieve high-quality surface repair and coated.

Efficiency: Laser cladding equipment has fast processing speed, can quickly complete surface repair and coating tasks, and improve production efficiency. At the same time, the automated robot system can run continuously, reducing downtime and increasing the utilization rate of the production line.

Flexibility: Industrial robots can be programmed and adjusted according to different workpiece shapes and requirements, adapting to diverse workpiece and process requirements. By changing the laser focus position and scanning path, cladding operations can be performed on different surface shapes.

Fine control: Laser cladding equipment can realize local cladding, only operate in the area that needs to be repaired or coated, avoid heating the entire workpiece, reduce the heat-affected area, and reduce the risk of deformation.

Material adaptability: Laser cladding can be applied to a variety of materials, including metals, ceramics, etc., and can achieve high bonding strength and good interface quality between different materials.

Environmental protection and energy saving: No additional chemicals or solvents are used in the laser cladding process, which reduces the pollution to the environment. At the same time, laser energy can be precisely controlled and positioned to avoid energy waste and save energy.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR