Robotic Laser Machine: The Future is Here

Would you wonder what the future shall seem like? Will we be traveling around in flying cars or staying in houses made of glass? Well, the long haul will be around and it comes in the form of the DMKrobotic laser machine. You might be wondering just what a laser machine is and how it might probably gain. We are planning to explain anything need to learn when it comes to a robotic laser machine, including their advantages, innovation, safety, use, how to use, service, quality, and application.

Advantages of this Robotic Laser Machine

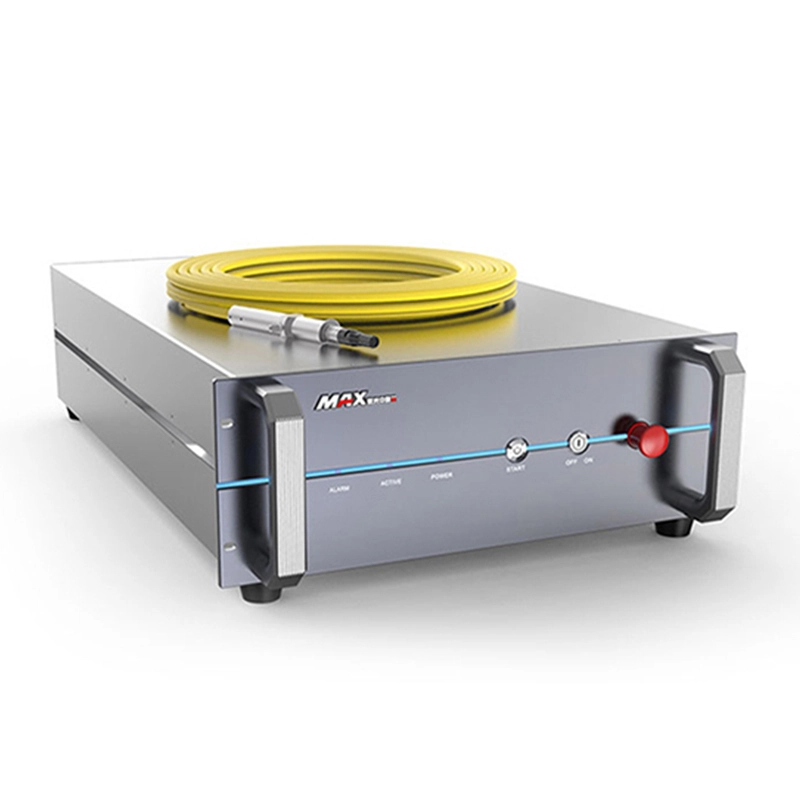

A robotic laser machine are the device works on the bigger strength laser beam to cut, weld, or mark content. There are several advantages to using arobotic laser equipment, including:

1. Precision: a robotic laser machine can cut through items and accuracy is amazing creating it an amazing tool for manufacturing applications need precision.

2. Speed: a robotic laser machine can cut with materials in the much faster rate than the usual human operator, creating it an excellent device for higher volume manufacturing.

3. Versatility: the robotic laser machine may be properly used for a true number of items, like metal, plastic, wood, and considerably.

4. Efficiency: a robotic laser machine features a lifespan is long makes it an economical investment for companies.

Innovation in Robotic Laser Machine

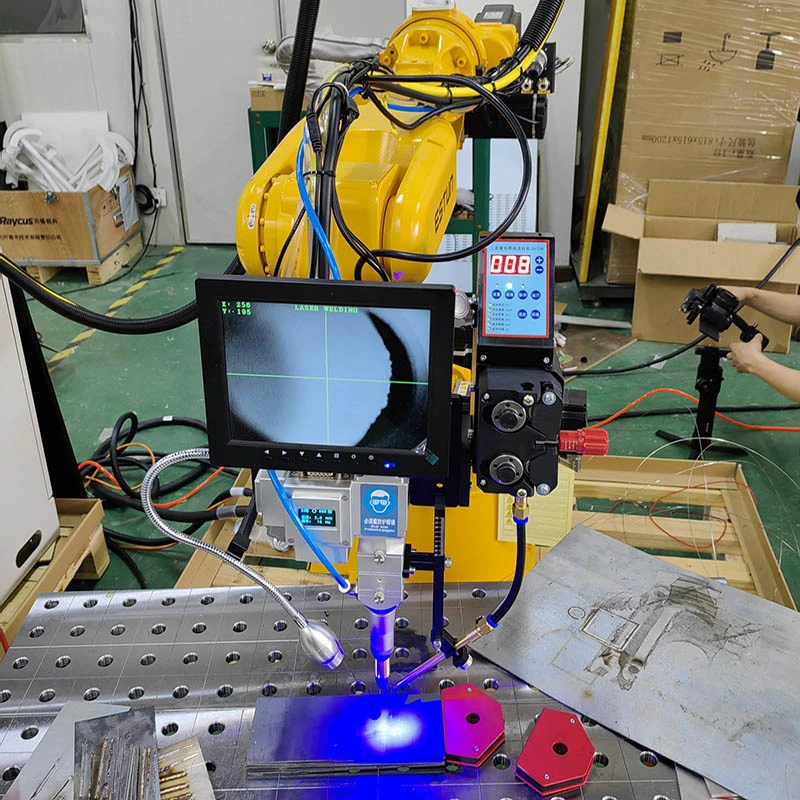

Innovation try travel the rise of robotic laser devices. Plenty of nowadays devices include high level features like automatic focus adjustment, real time monitoring, and high level programming algorithms. The machines is manufactured by these features quicker, most reliable, and safer to use.

Safety Features of the Robotic Laser Machine

Safety is a top priority for manufacturers and customers ofrobotic laser welding machine. These machines is designed with many safety features, such as light curtains, interlocks, and emergency stop buttons, to avoid injuries. Personnel dealing with the machine must learn on how to use it properly.

How to Use a Robotic Laser Machine?

Employing a robotic laser machine involves 3 main steps.

1. Program the machine: using specialized software the programmer creates the designhat the laser machine follows.

2. Set the machine up: the operator loads the materials in the machine and sets the machine's parameters for cutting, welding, as marking.

3. Run the machine: the operator activates the machine, and it starts to cut, weld, or mark the components.

Quality Assurance and Service when it comes to Robotic Laser Machine

Quality is essential in production andRobotic Laser Cleaning Systemcan help ensure a greater level of quality control. Most machines are ready and sensors and computer software monitor the machine's performance and detect any defects. Furthermore, providers offering service is regular maintenance tools to ensure your machines continue steadily to operate efficiently.

Application of Robotic Laser Machine

Robotic laser machines can be used in a lot of industries, like:

1. Manufacturing: robotic laser machines is priceless hardware for cutting, welding, and marking materials in the manufacturing industry.

2. Automotive: robotic laser machines are employed to make car equipment, such as exhaust techniques and doors.

3. Aerospace: robotic laser devices are used to produce parts for aircraft, such as control areas and landing gear.

4. Medical: robotic laser machines are acclimatized to manufacture surgical instruments and products.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR