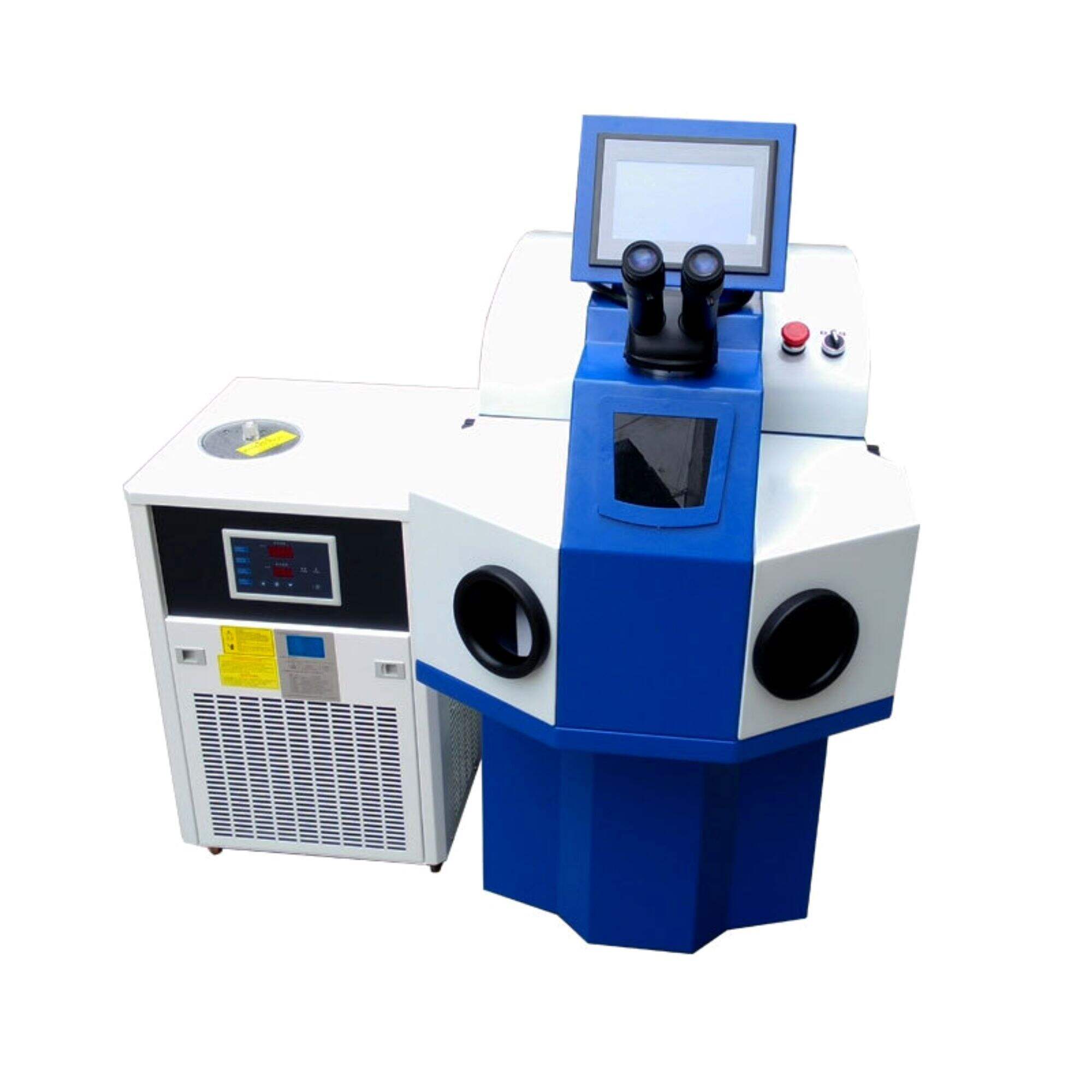

Discover the Top 4 Jewelry Laser Welding Machine Manufacturers in Australia

Have you been searching for the best jewelry laser welding machines on the market? Search DMK because Australia has got you covered. The following content a high four Jewelry Laser Welding Machine Manufacturers in Australia, their various advantages innovations, safety, use, services, quality, and application.

Advantages of Jewelry Laser Welding Machines

Jewelry laser welding machines are popular among jewelry manufacturers for different grounds. Firstly, they provide a level which is a lot of helps to make sure that jewelry repairs and customizations are done accurately. Secondly, they have a quick wedding which guarantees that jewelry efforts can be achieved effortlessly. Thirdly, they could weld metal of varying thickness that give them the versatility had a need to work and various types and diameters of jewelry.

Innovation in Jewelry Laser Welding Machines

Australia's top jewelry laser welding machine manufacturers are continuously innovating to produce laser rust removal gun better and more efficient machines. They incorporate the current technologies to enhance machine efficiency, accuracy, and safety. Laser welding technologies have continued to develop significantly, and the top manufacturers held up with the full days to supply the best machines with their consumers.

Safety of Jewelry Laser Welding Machines

Safety is very important to both the manufacturers and the users of this jewelry laser welding machine. These laser cleaning machine for rust removal machines come and integrated features make sure the safety of an individual. These features include LED lights, protective glasses, safety covers, and automatic shut-off. The manufacturers adhere to strict safety and conduct thorough evaluating before releasing the machines into the market.

Use of Jewelry Laser Welding Machines

Jewelry laser welding machines are employed in different jewelry-making procedures. These are typically well suited for fixing or customizing jewelry. These machines are also beneficial in producing new jewelry. They utilize various metals like gold, silver, platinum, copper, and metal. They can weld small parts, rocks and beads without damaging them.

How to Use a Jewelry Laser Welding Machine

Using the jewelry laser welding machine might seem complicated, but as soon as you learn the method, it is direct. Firstly, be sure that you place the cups, protective glasses and gloves. Secondly, prepare the steel parts with a soap that you need to weld by cleaning them. Thirdly, put the metal parts into the appropriate position adjust the settings in the machine. Fourth, start the machine, and the laser beam shall fuse the steel parts together. Finally, examine the right welded parts clean them if required.

Service and Quality of Jewelry Laser Welding Machines

The most effective 4 Jewelry Laser Welding Machine Manufacturers in Australia provide fiber laser cleaning machine exemplary service and top-notch machines. They provide an array of solutions like classes, tech support team, installation, preventative maintenance, and repairs. They also use top-notch materials and advanced technologies so that the machines are related to best quality.

Application of Jewelry Laser Welding Machines

Jewelry laser welding machines may be used in repairs, customization, and production. In repairs, these machines are used to restore the integrity of damaged jewelry parts. Customization involves using laser machines to create individualized jewelry consumers. In production, these machines are accustomed to fuse different metals together to produce intricate jewelry.

Table of Contents

- Advantages of Jewelry Laser Welding Machines

- Innovation in Jewelry Laser Welding Machines

- Safety of Jewelry Laser Welding Machines

- Use of Jewelry Laser Welding Machines

- How to Use a Jewelry Laser Welding Machine

- Service and Quality of Jewelry Laser Welding Machines

- Application of Jewelry Laser Welding Machines

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR