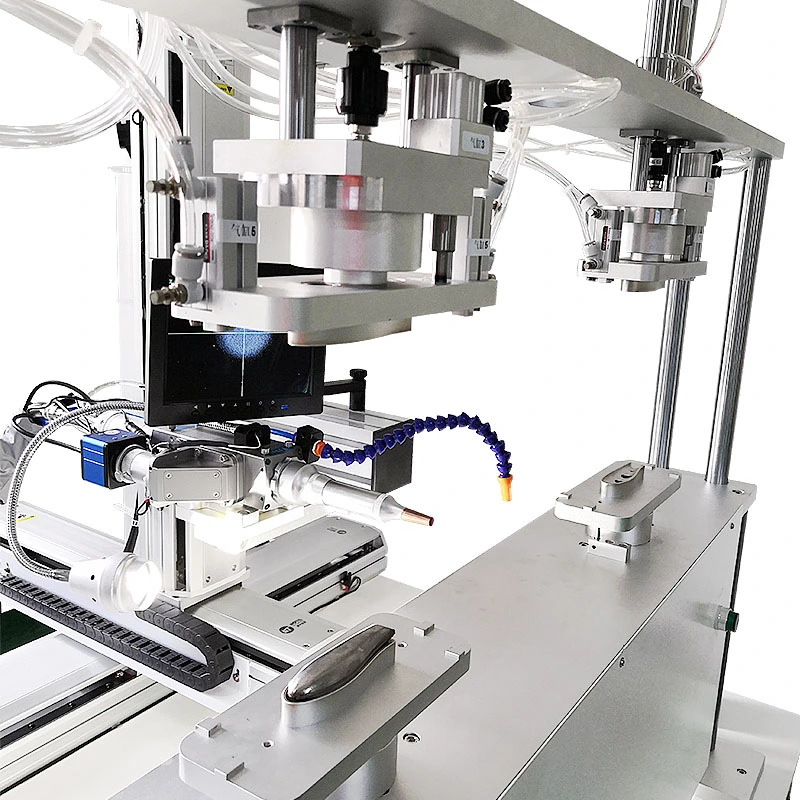

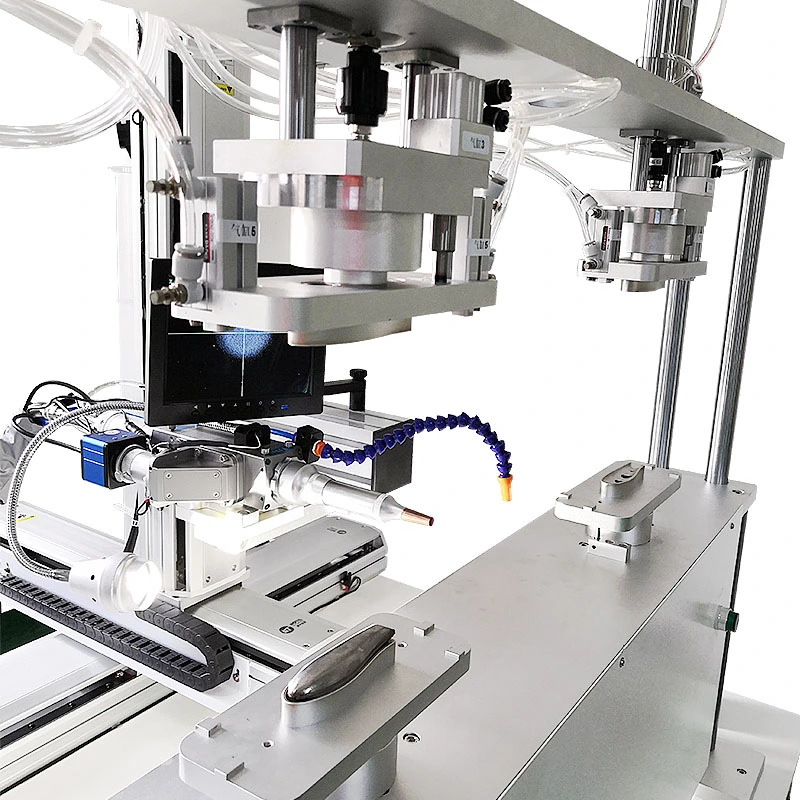

Multi-Axis Linkage Laser Precision Machining Technology: An Innovation for Quality Service

Laser cleaning machine for rust removal has built via the whole years, and also numerous industrial locations currently depend on it to ensure exact and also end results being specific. Among the most recent technologies is linkageDMKlaser rust removeraccuracy machining innovation that's multi-axis. This innovation is altering simply just how makers develop items, which is charm that's obtaining its lots of advantages.

Benefits of multi-axis linkage laser precision machining technology

Laser Cleaning Machine accuracy machining modern technology brings accuracy and accuracy that's high manufacturing. With this certain modern technology, many lasers can be used all at once in a variety of standards at numerous point of views to create a very precise and thing that's outlined. This modern technology gives higher end results compared to antique machining methods, such as as an example milling and machining. Another excellent aspect of multi-axis linkage laser accuracy machining modern technology is its price. This modern technology allows quickly and manufacture that's efficient can generate components in document time. Likewise, this modern technology can procedure a variety of products, consisting of steels, plastic products, porcelains, and compounds.

Innovation in multi-axis linkage laser precision machining technology

1000w rust cleaning laser accuracy machining innovation brings technology to manufacturing, making it possible for much far better efficiency and also accuracy. This innovation can possibly attain better amounts of accuracy (as much as 0.001mm), makings it perfect for intricate and also detailed layouts unlike various other manufacturing techniques. Moreover, it might create 3D types and also engrave intricate routines into various products, makings it an innovation that's excellent the production of customized elements and also models. This innovation has actually obtained the possible to improve production procedures in a variety of firms, consisting of aerospace, automobile, and also clinical.

Security factors in multi-axis linkage laser precision machining technology

Viarobotic laser welding machineaccuracymachiningmodern technologybringsadvantageswhich arelots ofit'simportanttothink ofprotectionwhenmaking use ofthismodern technology.Thedriverswillshouldhave actuallyeducatingthat'senoughsuitableprotectionprocedures,consisting ofutilizingsafetyequipmentsuch asfor instancehandwear covers,safety glasses,and alsofull-faceguards.Likewise,thegadgetsought tobe heldhealthyand alsoundertakeroutinemaintenancetoensuretheirsecurityand alsoperformancethat'ssuitable.Securitysystems,such asas an examplesituationfinishswitchesand alsolaserpoweradjustmentcapability,have tobeestablishapproximatelypreventcrashes.

Utilizing multi-axis linkage laser precision machining technology

Users of portable laser lust removal machineaccuracymachininginnovationought tohave actuallyspecificfinding outcomputersoftware programlaserand alsogrowthmachining.Theinnovationrequirescomputersoftware programthat'sspecifictocreatelayoutsand alsoproduceG-codestandards.Theinstructionswhichcan possiblybe g-codeafter thatsigned up withintothe system tostartthe machiningtreatment.Thedriverhave tomake certainthat theitemusedcollaborate withassistedby theinnovationto avoidinjuryto thetools.Ultimately,thedriverneed tocheckthetoolthroughout the machiningtreatmentandmakeadjustmentswhichcan possiblybeessentialmake surethat theseitemsare ofhigh qualityand alsoaccuracy.

Service and quality in multi-axis linkage laser precision machining technology

The caliber of the services and products produced determines the degree of solution to clients much like any production technology. Withhandheld fiber laser welding machinetechnology quality is assured. The technology utilizes computer software that is contemporary to make sure that items meet up with the desired requirements. Moreover, the technology permits the manufacturing of top quality components at an price that is efficient. This leads to economical production and helps to ensure that the clients get top notch items at a cost that is reasonable.

Applications of multi-axis linkage laser precision machining technology

Laser rust removal equipment precision machining technology has actually in fact applications which can potentially be great deals of. It could make a differ that is huge of, from aerospace elements to scientific things, as well as tailor them to satisfy the demands of countless organizations. The technology can potentially be made use to create electrical electric motor elements as well as turbine blades into the aerospace market. Into the car market, its utilized to construct components being numerous including devices as well as cams. Theportable laser rust removal machinecan potentially be made use to produce components for implantable things, scientific devices, as well as dental prosthetics within the scientific market.

Table of Contents

- Benefits of multi-axis linkage laser precision machining technology

- Innovation in multi-axis linkage laser precision machining technology

- Security factors in multi-axis linkage laser precision machining technology

- Utilizing multi-axis linkage laser precision machining technology

- Service and quality in multi-axis linkage laser precision machining technology

- Applications of multi-axis linkage laser precision machining technology

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR