How to replace the laser output optical cable. Replacing the laser output cable that is optical is important to maintain the reliability and durability of one's laser equipment. To stop the potential hazards, it is essential to improve performance. Let us talk about the advantages, innovation, safety, use, and application of replacing laser output optical cables.

Advantages

It is simple to enhance the transmission efficiency associated with the DMK laser beam welding, produce top-notch outputs and increase the duration regarding the optical cable when you exchange the laser production cable that is optical. A cable that is damaged is caused by worn-out laser performance, frequent downtimes, reduced productivity, and increased repair costs. Nonetheless, you can easily optimize the laser system's effectiveness and minimize outages with a laser that is a new optical cable.

Innovation

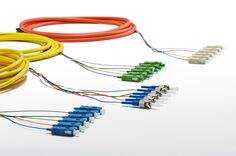

The innovation of the latest laser output optical cable is through utilization of high-quality materials to improved, durability, flexibility and compatibility. Laser output optical cable is a product of continues advancement of technology. The installation of the brand-new designs provides a connection, rendering it hassle-free when replacing the cable.

Safety

Safety should always be a priority, so in retrospect replacing the laser output optical cable is critical. A hazardous situation is a result of damaged or worn-out DMK fiber laser source repair cable that can be the reason to fail the laser beam. The threat of blindness is a severe injury that may happen. Ensure that the laser equipment is turned off when replacing the cable and should be followed by safety protocol.

Use of the laser output cable that is optical

A laser production optical cable is required in various applications, including surgical procedure, medical research, and production that is industrial. Medical procedures such as surgeries require DMK clean laser beams that are effective and adequate to perform precision incisions, reduced hastening and bleeding data recovery. Based on scientific research, top quality lasers that are optical give accurate information when laser beam interacts with environment and materials. Whilst industrial production can produce quality, top DMK laser cleaner optical cables are used to process materials.

https://www.pinterest.ph/

How exactly to use

Stick to the fundamental steps whenever replacing the laser output cable that is optical. First of all, laser equipment must be turned off and unplugged through the charged power supply. Next, Unscrewed the cable that is old the DMK fiber laser source source and the receiver end. Third, make sure that the fibre connectors are clean and free from any debris then connect the cable that is latest. Finally, make certain that the production is suited when you test the cable switching with the brand-new laser gears.

https://www.pinterest.ph/

Service and quality

You should always provide value that is best and a dependable service provider whenever replacing your laser optical cable. It is necessary that the ongoing company should have expertise within the laser industry and comprehend the particular requirements regarding the equipment. Are the warranties and guarantees once you need to research and compare different providers to obtain the deal that is better. A site that is dependable and cable that is top-quality you can be confident that your DMK clean laser cleaner gear will work effectively.

It is important to know the cable is new of high quality, easy-to-install and reliable. When replacing the laser manufacturing optical cable, it is essential part that the durability, reliability, and gratification associated with laser gear. Furthermore, it is important to aided by the safety and the protection is concern whenever laser is utilized. Utilizing the suggested actions, you’ll confidently replace your laser manufacturing cable that optimizes that optical laser’s performance.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR